Is there any one main causing factor for bullet set back to occur?

The nose of the bullet is driven into the feedramp during recoil.

With that being said, is there any way to prevent this from happening or is it perfectly normal?

Quote:

The nose of the bullet is driven into the feedramp during recoil.

Not to pic nits, Eric, (because I read your posts and "know" you know much more than me)... but you mean during "feeding"?

Because set back happens on chambering whether the pistol was fired or not.

Jn316, mags can make some difference... the position of the bullet in the mag makes a difference too.

The top round on a full round sets back the most.

Niemi has a pic here showing where the round bangs off the feed ramp at different places depending whether the round was the first or last rnd in the mag.

Some ammo sets back more than others too.

From my tests, Blazer (aluminum case) sets back the worst.

Blazer Brass is second worse.

Winchester white box (WWB) was appx half as much set back as Blazer (aluminum)

Federal American Eagle and Aguila are the ONLY rounds I've tested that showed virtually NO set back on multiple chamberings.

which is kind of interesting to me that Fed AE suffered no set back, cause Fed Hydro-Shok suffered an average set back of .006 on one chambering and it has a cannelure crimp grove on the case.

I notice that if you hand cycle to feed a round the setback is less than if you drop the slide. Particularly if the pistol cycles smoothly.

Quote:

...is there any way to prevent this [bullet setback] from happening or is it

perfectly normal?

It's prefectly normal for an M1911A1 to try to set the bullet back. And the only way I know of to prevent it is to use ammunition (such as GI Ball) with the bullet sealed to the case. That's for a setback of zero - essentially too small to measure if not actually zero.

As mentioned in previous jposts, setback can occur when the bullet hits the frame feed ramp if the top round in the magazine stikes it during recoil or when it's being fed. Some setback can also occur during feeding when the bullet hits the top of the chamber. Some tests I did showed the vast majority of setback (70 to 95% of it) occurs during feeding when (and if) the bullet hits the frame feed ramp.

If there is a single main cause of setback in the 1911 it's the angle of the magazine - and we can't fix that. Here's a few of the other factors:

* Number of rounds in the magazine (top round in full magazine will set back

the most)

* Magazines with feed lips deformed on their aft, undersides (tend to trap case rim and make slide torque the bullet down during feeding)

* Guns with frame feed ramps that are too steep

* Ammunition whose cases have a weak grip on the bullet

How much setback is too much setback? From the increased pressure standpoint, I don't know. But from the feeding standpoint it's when setback results in the cartridge causing an FTRB.

I save my ammo that's noticeably set back from repeated re- chambering/feeding, and every so often I put them in the kinetic bullet puller (only pull part way, not all the way out); then they go in station three of my press for seating, then station four to re-crimp.

I then use them as range ammo, and they work fine.

+1 for McC.

Also exactly what type of ammo are you using? Factory or handloads? Details on whichever you're using will also help.

If you chamber the same round over and over again it will set it back. Sometimes just as few as 5 times does it already and its noticeable when you put it side by side with another round that you havent chambered yet. I speak from experience of my stupidity

Quote:

Also exactly what type of ammo are you using? Factory or handloads? Details

on whichever you're using will also help.

Been using my reloads 200gr SWC @1.240

Just got done installing an EGW fps and HD extractor and while hand cycling noticed a bit of set back and ended up doing like Rick McC said with the puller

Measure the setback you get when the top round in your filled, highest capacity magazine is fed by slingshotting it.

Q: How much setback do you get?

I use a Clark Custom Gun 460 Rowland conversion on my Colt O1070XSE.

Clark requires conversion owners to discard any chambered rounds to be discarded if not fired. The bullet set-back with one chambering is dramatic and a second chambering would cause a significant increase in pressure to the point of possible catastrophic failure.

Here is a photo of a once chambered round in my Colt:

Notice the lack of a cannuler or crimp.

Check your COAL and chambering results in your weapon.

It could save your life, or finger!

Quote:

Q: How much setback do you get?

Did a three slingshot test starting @1.242

1- 1.241

2- 1.239

3- 1.2385

The brass I am using is Winchester (reloaded maybe four or five times) with a tapered crimped @.471 bullet dia..452. Mag is a brand new Checkmate 7rd Hybrid w/flat follower. The 1911 is a 70 series Govt. all stock except for the for extractor and FPS upgrades.

If those were with a full magazine, the setbacks are zero for all practical purposes. The Winchester brass I've measured has some of the thickest walls and provides a good grip on the bullet. You'll get more setback with thinner brass such as CCI, CBC and Speer - and crimping more probably won't help.

But with the same round repeatedly chambered, the setdback simply adds up. Chamber one of those rounds the same way 10 times and the bullet will probably get set back about 0.025" to 0.030". But I've seen some handloads set back 0.030" in a single chambering!

I have not posted about my setback issues with my Rowland in a long time, but I did blow a round and slide and magazine years ago due to bullet setback. Sounds like you have a handle on it, but I thought I might throw out a couple of things just in case (and this can pertain to the op).

Obviously bullet shape makes a big difference here, as well as oal. I have also found that the original Colt taper style feed lips are the most forgiving across the boards for all bullet shapes, including 250's. And most importantly for me, I am running the fps mod, heavier mainspring and a 20# ISMI spring. No 24's in my gun anymore, period. The ISMI chrome silicon takes less of a oal set, and does seem to have greater "closed" pressure, if you are concerned with this. And none of the potenetial grief of the very heavy and fast slide cycling speed with the 24.

If you have not played with the various feed lip styles in magazines, it might be worth a look. I have tested quite a few, with some pretty wide and crazy bullet shapes, and the worst for me are Wilson mags. They do work, don't get me wrong, but I am talking about not just feeding but smooth feeding. It does not surprise me that Wilson would suggest discarding any unfired fed round, one as a general safety precaution, and two as in my Colt their mags are the ones most likley to cause setback with certain bullet shapes. I never see first round setback like you have depicted, anymore.

Quote:

Notice the lack of a cannuler or crimp.

Please don't get the idea that the lack of a visible crimp contributes to setback. Get yourself a 460 Rowland crimp die and crimp away. Bet you a dollar to a donut any crimp will increase setback!

Have you ever seen any commercially loaded jacketed bullet automatic pistol ammunition with a visible crimp?

Have you ever wondered why you haven't?

The Rowland uses 45acp dies, so us "Rowlanders" don't need custom dies. For the record I do tend to crimp just a tad heavier than acp rounds, a taper (obviously) right around .469 to .470, depending on whether or not I am using .451 or .452 bullets, and what construction.

What I can say is that trying to mondo crimp will goof things up accuracy wise, case wrinkling wise and not make a bit of difference towards bullet setback. With the Rowland, I feel that setback seems to be related to gun tolerances/construction, bullet shape, magazine feed lip style then oal, mostly in that order. All compounded by the 24 lb spring that most use. That should sound suspiciously similar to a 45acp list, winky winky.

What I also feel is accurate is that the kind of setback that Browning posted, if just from one feed, is totally unacceptable in any 1911. Mostly tollerable in a 45acp if you are lucky, headed for case failure (and potentially a life changing event) in a Rowland. Fortunately for me, my life changing event only wrecked one slide, and forced me to get my head around some things that I had been obviously missing. Thankfully all of the good folks here, yourself included, have been great to help me change my 1911 life. And I can still type with all 10 fingers

The most setback he had was 0.0035" and you feel that's unacceptable? Hmm-m-m- m.

I thought it was real good, especially if it was on the top round in a full magazine. Just for comparison, here's some setbacks I've measured when fed as the top round in a full 7 round magazine, (HL) = handload:

* (HL) 200gr cast LSWC in Winchester case = 0.000" (my usual handload)

* Federal American Eagle 230gr = 0.003"

* (HL) Hornady 230gr JRN in Winchester case = 0.004"

* Winchester USA 230gr JRN (WWB) = 0.008"

* Remington-UMC 230gr JRN (green & white box) = 0.013"

* Speer Lawman 230gr JRN = 0.018"

* (HL) Hornady 230gr JRN in R-P (not R.P) case = 0.020"

* CCI Blazer Brass 230gr JRN = 0.022"

* (HL) Speer 200gr LSWC in R-P (not R.P) case = 0.028" (but as only round in magazine)

Anyway, when I'm thinking jn316's 0.0035" is pretty good, that's what I'm basing it on - because I've seen lots worse!

Craig, thanks for the input. I have found a few interesting facts about the 460 Rowland and a stainless steel (slide and receiver) set-up.

First the 24# provided recoil spring was inducing FTF and FTRB issues at a 80%+ rate and my cell calls to Renee at Clark became a speed dial function.

Here are a few idiosyncrasy's of the conversion kit that are not covered in the Rowland FAQ section.

The coefficient of friction of stainless is way different than that of carbon steel and when you're throwing 200 grain led downrange at 1,500fps, physics dictates the original JMB design slide timing is thrown off a tad. When you add in the "new" alloy of stainless steel some modifications to the original/contemporary 45 ACP criteria are needed.

The extractor was functioning to spec.

The first thing I did was to use the Wheeler Engineering Lapping Compound Kit (220, 320, 600 Grit Compound) on both the barrel bushing and slide rails. This helped a great deal but did not eliminate the FTE/FTRB problem. It did reduce it to about 50%.

My next observation was that the FTE cases had no witness mark where it was suppose to be hitting the ejector. The slide was not fully cycling rearward. Too much recoil spring.

I too am a big believer in the technology used in the ISMI springs and had heard about Marc Cosat and his springs while I was a design engineer at General Motors. (Before Barack owned them)

I started to step the spring pressure down in search of a running 460.

Well when I got to 16# and was still having FTRB issues, Clark told me they "could not tell me to go lower" wink, wink. Well when I reached 14.5#s the gun was running flawlessly. I was using Rem Oil (always do) and found out that Clark has a recommended lube for SS Rowland kits?? They sent me a sample of Firepower FP-10 CLP. NOOOO, I couldn't have got that suggestion 2,000 gray hairs ago! Spring pressure is back to stock 45 ACP 16# and after another 250 rounds I think I'll step up to 18#.

In conjunction with the spring testing I also switched from Wilson Combat ETM (p/n500B) mags to Tripp Research Gen II Cobra Mags.

The Tripps have CNC finished feed lips. This is not the only improvement they incorporate into their Cobra design.

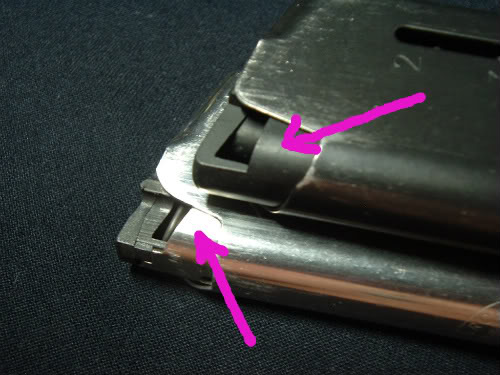

Find the weld seam on the Tripp:

Look at the fluid form of the Tripp and the seating of the round against the mag back:

This shows the difference in the followers. The Tripp hybrid has a metal interface where it engages the slide stop. The Wilson only has ~300 rounds downrange and you can see the witness wear mark on the poly follower interface

What a difference this change made. Both feed and setback issues were significantly reduced.

If you're going to modify, be prepared for the high maintenance!

Should have mentioned that all those setback figures in Post #18 were for 45 Auto ammunition in a M1911A1 with either a 14 or 16 pound recoil spring. The magazines were either a Colt hybrid lip or an original long tapered GI lip modified to a hybrid release point. [Edited: Setbacks were from a single chambering.]

I think we missed each other in our earlier threads. I was posting in response to Highpowers picture of the Rowland setback which is way more than 0.0035. Heck, you can get 0.0035 variability in seating depth with the wrong combination of bullet hardness/shape and seating plug. Just the act of chambering a hollowpoint can give that with nose deformation which can confound measuring. So, 0.0035 should not be problematic in an acp or even a Rowland. Thanks for your testing, as I think proves that you can eliminate setback, but I think we all can see that as we are talking about a system, everyones mileage will vary. And I think this is the value to a thread like this, everyones mileage WILL vary, as their 1911 system is not identical to yours or my 1911 system. Dang, if we could figure out how to get your testing and measuring results mixed in with my cad abilities we could do some pretty fine graphics. Well, perhaps not, I actually like your drawings

Highpower,

Thanks for the detailed reply and experiences. I have been Rowlanding for

many years, currently having 4 kits (unless you count my 5th with sheared

lower lugs) that I have experimented on quite a few frame/gun combos. Your

information on the stainless is very intersesting, as my current setup is a

stainless Clark on a new Series 70 repo.

With my stainless Colt, I have seen nothing like you experienced. It ran from day one perfectly, with the 24, albiet with the dreaded 24 pound return velocity. No galling type issues. If I were to install a 16lb spring, I would likley have brass landing in the next county. I have used a version of FP10, but for quite some time mostly Tetra.

My decision to go to the 20 ISMI was made a few years ago, after getting my head around how and why the 1911 feeds, magazine feed lips, and most importantly understanding the EGW fps and assorted mods. Mark at ISMI told me that he felt the 20 cs spring would likley hold a better/higher locking spring rate compared to the Wolff 24, as both springs were used for a moderate number of rounds (spring set). A couple of years of testing over several kits sure seems to bear this out.

Back to the op track, I have never tried the Tripp mags as a way to deal with bullet setback, as I was fortunate enough to have found the older threads here by Tuner, Niemi et.al. talking about original Colt taper design v. all of the newer "high-tech" designs. I dug a couple of old original Colt mags from the safe, and presto bango perfect feeeding. Go figure. So now I am content to order factory Colt mags from Brownells. problem solved. That and avoiding 250 grain semi wadcutters...

And to the op, sorry for the Rowland drift, but the one thing the Rowland does is magnify many of the issues that acp users have. Especially things like attempting to fix feeding problems by tossing in heavier springs which can cause other issues. I suspect that many many folks have setback "issues" but due to the lower operating pressures either get away with it, or do not even notice it. With the Rowland you really have to notice everything.

Back to a proper Rowland hijack, Highpower, I performed some interesting wet newsprint penetration testing a few weeks ago with 3 different Hornady XTPs and 3 different "solids". Saw some things I thought were kinda interesting. I have been meaning to start a thread, but I need to get my noodle around picture hosting with my new phone.

Quote:

I think we missed each other in our earlier threads. I was posting in

response to Highpowers picture of the Rowland setback which is way more than

0.0035.

Yeah, I had a suspicion we were referring to different things, but wasn't sure. Thanks to the inclusion of the rule in his 460 Rowland pic, it's pretty easy to see BrowningHP's got about 1mm or 0.04" of setback there. That's quite spectacular!

But when you consider the 24lb recoil spring - maybe not so spectacular after all. I fuzzily recall getting about 0.032" with a soft Speer LSWC in a R-P case one time and with only a 14lb recoil spring! And that was the only round in the magazine!! Most ammunition tested shows about a 7X increase in setback between the only round and the top (7th) round, so I'd estimate the Speer would have set back about 0.2" as the top round in a full magazine.

0.2"? Now that's spectacular! Wish I had some more of those squishy-soft things to find out for sure.

jn316, I too am sorry for the 460 hijack but must echo Bearbait that the Rowland experience is like looking at your 45 ACP issue under a microscope.

My sole purpose is a knowledge transfer to assist you in resolving your problem.

When looking at bullet set-back, the "Usual Suspects" are generally the bullet's meplat (nose geometry) and the mag's ability to maintain design timing of the cartridge release from the mag's feed lips to the slide's breach face and extractor capture.

Quote:

Thanks for the detailed reply and experiences. I have been Rowlanding for

many years, currently having 4 kits (unless you count my 5th with sheared

lower lugs) that I have experimented on quite a few frame/gun combos. Your

information on the stainless is very intersesting, as my current setup is a

stainless Clark on a new Series 70 repo.

With my stainless Colt, I have seen nothing like you experienced. It ran from day one perfectly, with the 24, albiet with the dreaded 24 pound return velocity. No galling type issues. If I were to install a 16lb spring, I would likley have brass landing in the next county. I have used a version of FP10, but for quite some time mostly Tetra.

I'm thinking my Colt was to blame. I built the Rowland along with a friend who converted a Kimber. As I went gray fixing my issues his fell together and was running in the first week! My Colt ran flawlessly as a 45 ACP and my concern was I inadvertently had done something to the piece. A quick return to 45 showed no issue in the stock configuration. Now the gun is running well I can fire both 460 and 45 with no spring change. (I don't do that much but the engineer in me wasn't happy until I knew it would!)

Quote:

My decision to go to the 20 ISMI was made a few years ago, after getting my

head around how and why the 1911 feeds, magazine feed lips, and most

importantly understanding the EGW fps and assorted mods. Mark at ISMI told me

that he felt the 20 cs spring would likley hold a better/higher locking spring

rate compared to the Wolff 24, as both springs were used for a moderate number

of rounds (spring set). A couple of years of testing over several kits sure

seems to bear this out.

I too have spoke to Mark and am impressed with his use of CS springs over music wire. And trade secrets keep me from disclosing his customers but it's safe to say you are probably using his ISMI springs in products branded differently.

Quote:

Back to the op track, I have never tried the Tripp mags as a way to deal

with bullet setback, as I was fortunate enough to have found the older threads

here by Tuner, Niemi et.al. talking about original Colt taper design v. all of

the newer "high-tech" designs. I dug a couple of old original Colt mags from

the safe, and presto bango perfect feeeding. Go figure. So now I am content to

order factory Colt mags from Brownells. problem solved. That and avoiding 250

grain semi wadcutters...

Interesting you mentioned original Colt mags. As I waded through my issues I was picking up tips here and there. One I found helpful was with regards to friction again. It seems if you have a 1911 with timing problems, each improvement you can make helps return to design form. Case in point was the tip to try using magazines with metal followers. It appears that poly followers induce a drag on the round as it's stripped from the feed lips and slows the timing a tad.

Quote:

And to the op, sorry for the Rowland drift, but the one thing the Rowland

does is magnify many of the issues that acp users have. Especially things like

attempting to fix feeding problems by tossing in heavier springs which can

cause other issues. I suspect that many many folks have setback "issues" but

due to the lower operating pressures either get away with it, or do not even

notice it. With the Rowland you really have to notice everything.

Noticing everything is important! In a rush to get my Rowland running I neglected to swap out the firing pin spring to the kit provided HD version. There is a tremendous amount of physics happening with the 460 when you pull the loud switch.

The combination of the lighter spring and the violence of the round going high order, it was mushrooming the primer on the factory loads. The velocity of the slide recoiling managed to keep the FP spring compressed and as the case engaged the ejector, it was shearing part of this mushroom. With the FP spending this much time zen with the primer, I'm not sure how long it would have gone without failure.