Looking to add more tension to my extractor on an original 70 series colt government model. Too much brass in the forehead. Read many of the threads here and I think I don't have enough tension on the case.

However the extractor tunnel doesn't look like it would allow any more curve or tension against the case. There is no play in the tunnel where the extractor tip and hook come out. Looks like the cylinder is perfectly shaped for it not to be tuned.

Is it tunable in this slide or am I missing something? Please forgive the lack of experience.

First when you slide an empty case up under the extractor does it flex outward a little? if so the tension can still be increased. If the tip is not flexing at all then the pad of the extractor can be filed/stoned to allow it to come in further. Don't get confused thinking movement equates to tension, it doesn't.

No flex. There is still a gap between the rim of the case and the extractor. Didn't realize you had to remove material on the extractor pad, but that would be the only way to have tension on the case it appears.

Regarding movement. I was not looking at travel. Just that it would hold a case which it does not.

Also have had this pistol for ever and never modified. Do the older pistols just have wider tolerances? Not tight?

It might look like the extractor tunnel is too tight to add tension, but unlikely that it truly is.

You don't have to bend the extractor much to add or decrease tension.

Matter of fact, you generally can't tell any "eyeball noticeable" difference because the amount of bend you put on it is small.

They makes fixtures to adjust tension , but I do it by "feel" and test fitting a round

We'll assume we're working with a clean extractor tunnel.

(it's a good idea to clean it if you haven't in a while)

I pull the extractor appx 2/3 out of the tunnel then put pull/push the extractor in the direction I need tension (either more or less).

It's a pretty stout piece of steel and will need a fair amount of pressure to bend it... but it doesn't need bent much at all.

So little bend actually, that your eye won't perceive any difference.

So don't go McGilla Gorilla on it... start with very small adjustments.

Just a little pressure on it, then push it back in, slide the firing pin stop (FPS) back in... leave the firing pin out for now, but use the FPS so you know the extractor is in the correct position.

Then test tension with a round.

If more or less tension is needed, pull the extractor 2/3rds out and tweak as needed until you have the desired amount of tension.

To me that's enough tension to hold the round securely, but not a death grip on it.

Extractor tuning tuning instructions can also be found in our Tech Issues section http://www.m1911.org/technic2.htm and many find the following to be a good way too tell if the the tension is too great:

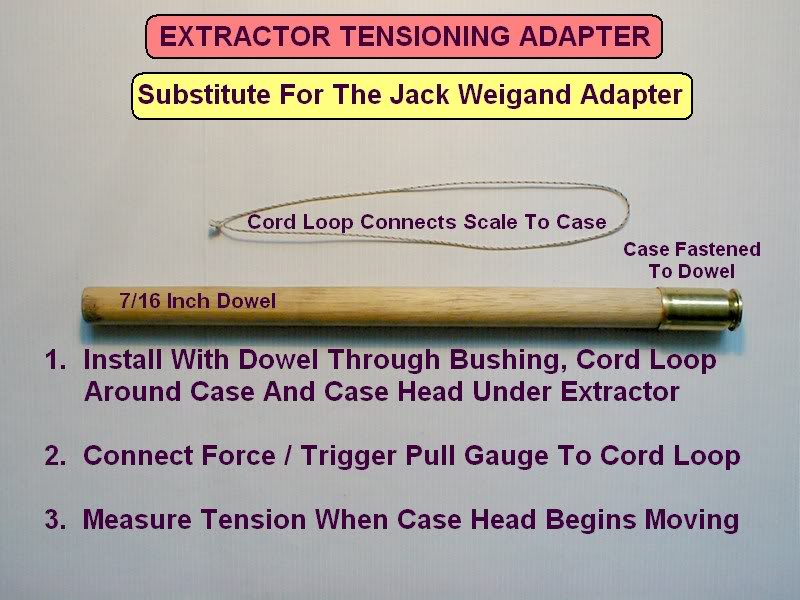

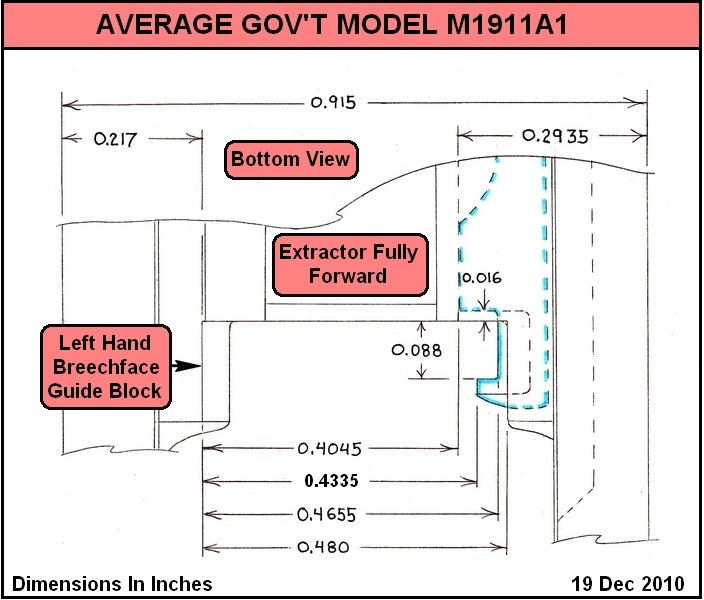

But about the only way to get scientific about adjusting its tension is to use the Jack Weigand method outlined here http://www.brownells.com/.aspx/lid=...ctor_Adjustment which requires the use of a force gauge or trigger pull gauge and an adapter. In lieu of Weigand's brass "dogbone" adapter, I use this...

..and read the tension the instant the case begins to move, sensing its movement with my fingertip. And FWIW, an extractor bent enough to provide sufficient tension can be a little difficult to install because it's "pre- loaded" by the slide.

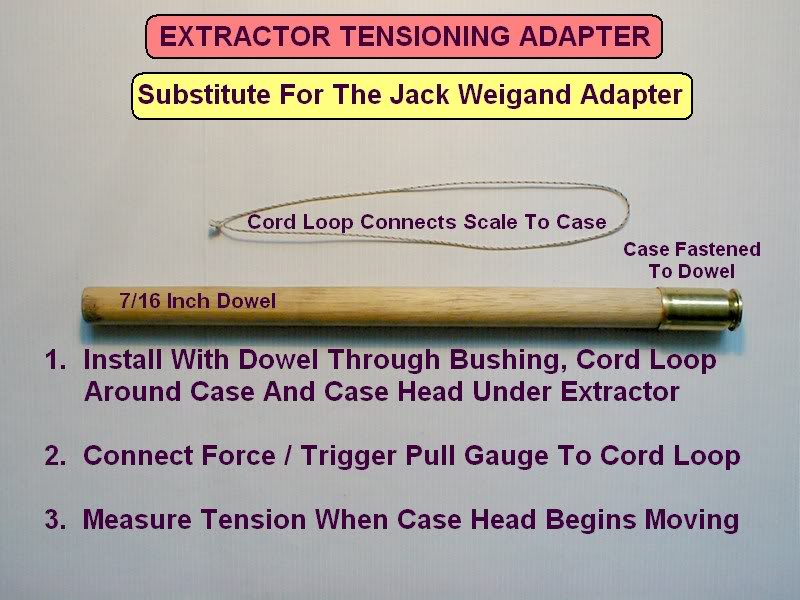

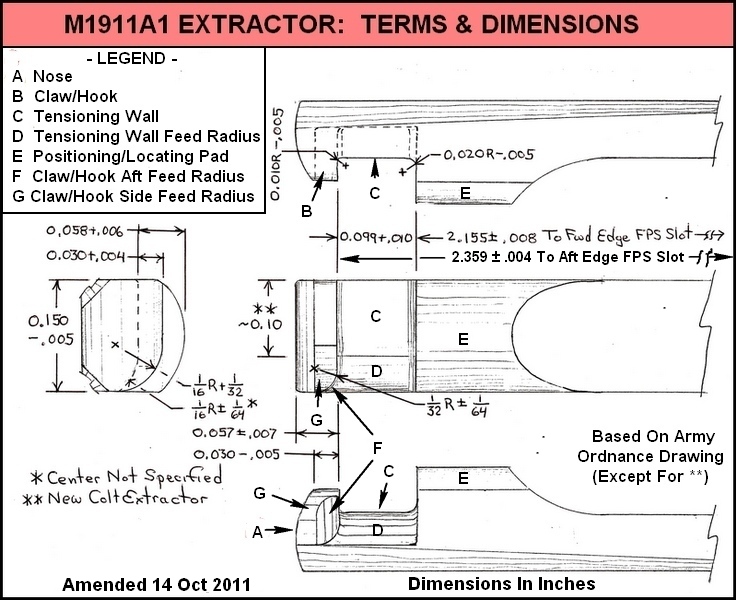

And if you suspect your extractor or slide may not be made to the proper dimensions, Ordnance blueprints for both are available in our Tech Issues section, 14th link down. Here's a clearer version of the extractor's business end and one of the extractor and slide:

Looks like I will have to remove material from the pad to get it to hold a case. I'm wondering now if it isn't broke don't fix it. Again probably the same extractor fit from when it was purchased in late 70's.

If, as you mentioned in Post #3, there is a gap between the case rim and the extractor's tensioning wall (item C in Post #6) that gap can result from:

* Extractor tunnel drilled too far to the right

* Distance from the pad to wall exceeds 0.064"

* Left hand breechface guide block too far to the left

* Extractor tunnel diameter is too small

* Dirt and crud have accumulated between the pad and tunnel wall which does not allow the extractor tip to go as far to the left as it did when the gun was new and clean.

I've heard Colt produced some 1911's years ago that were way out of spec in some areas. Before assuming yours is one of them...

...Q: When was the last time you removed the extractor and gave both it and its tunnel a good scrubbing?

I've cleaned the tunnel within the last 500 rounds. Although a bit dirty right now. I'll try and take some pics.

Some pics. Sorry I don't have any calipers.

Based on your photos and this..

Quote:

No flex. There is still a gap between the rim of the case and the

extractor.

...it looks like the only cost-effective way to get some extractor tension is to remove material from the extractor's positioning pad. You may indeed have one of those guns from what's called "Colt's Dark Ages".

When reducing the pad, all that's necessary is for the smallest case rim (SAAMI says 0.470") to push the pad a teeny bit away from the tunnel wall. Assuming the extractor and its tunnel are otherwise made to spec, the bend in the extractor holds the pad against the tunnel wall with some force - perhaps several pounds of force.

Quote:

"Too much brass in the forehead."

You may want to take a look at the ejector profile.

What should I be looking for with the ejector profile?

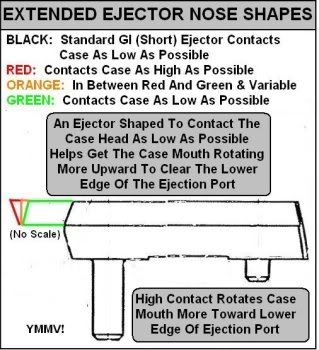

Generally, the ejector profile should be such that it contacts the case head down as low as possible, like the green one in this:

But don't start changing that until you get the extractor tension issue fixed. This may well cure the case on the forehead problem. One of the reasons why cases can be ejected straight back at you is because the case mouth hits the lower inside edge of the ejection port. This contact deflects the case mouth straight up and the rest of the case follows.

Take a good close look at the lower inside edge of your ejection port and look for a brassy-colored deposit/mark a case's length forward of the breechface. If you can't see anything, coat the area with typist's correction fluid to reveal any contact. I've a hunch you've got case mouths hitting there. But it's hard to say whether that contact is due to the extractor tension or ejector nose. Anyhow, don't do both at the same time: then you (and the rest of us) won't know which one cured the problem.

Wanted to give range update -

After reading the replies and those to another similar thread I put more tension on the extractor so that it was very tight in the tunnel. Thought maybe I would give this one more try as I am not comfortable taking material off the extractor pad yet. This of course did not produce any different results with holding a case in the slide. It would not hold a case with a little shake. Since this didn't do anything I took the tension back out of the extractor so that it was relatively loose again in the tunnel. Didn't feel it was necessary to have the extra tension since it did not change the position of the hook on the extractor.

Also above someone replied with ejector info. To clarify I have done nothing with this yet.

Went to the range today and put 200 rounds thru. The ejection pattern has changed. Seems to go straight up and well over my head. Indoor range so some coming off the ceiling. Only one ended up in my face and I think that was after rebounding off the ceiling.

So my theory is that even though I don't believe I ended up changing anything. My meddling cause something slight to change. Therefore before going after more extensive smithing sometimes it may be worth just playing a bit and seeing if anything happens. Slight changes even at the range can result in change...

Before taking it to a gunsmith, I would invest in a trigger pull scale and a set of Weigand extractor tension gauges from Brownells. If there is an actual gap between the face of the extractor notch and the edge of the case rim, the extractor cannot be properly tensioned, because (as you have discovered) no matter how much bend you put into it, it doesn't allow the extractor to contact the rim.

The extractor MUST make contact with the rim. You need to shave down the positioning pad a little, then (and only then) can you adjust the tension.

http://www.brownells.com/.aspx/cid=...extractor_gauge