...being referred to in this from TheFiringLine's "SW1911 External Extractor Adjustment" thread, Post #6, third paragraph

Quote:

(Nor, as mentioned above, is the tension checked in the same manner as is

done with an internal 1911 extractor, meaning that slipping a dummy round

under the hook and shaking the slide is not a relevant test).

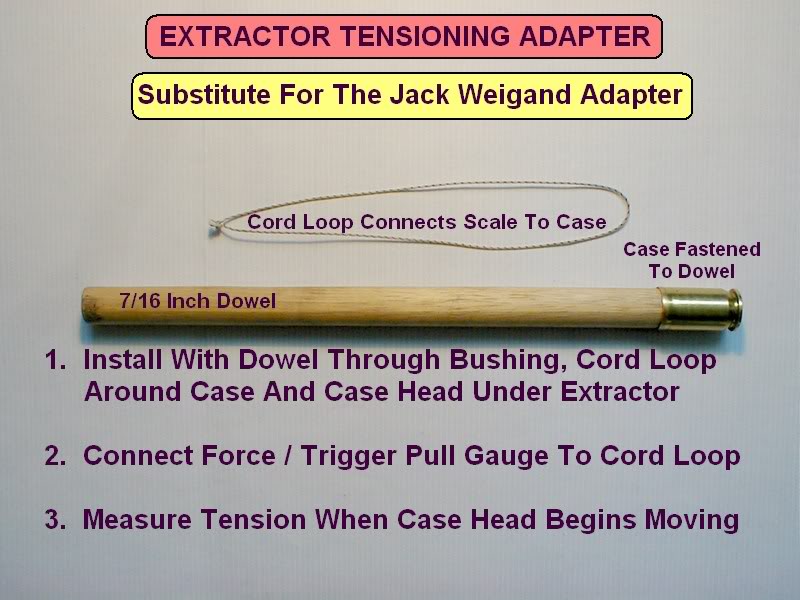

implies the tension of the SW1911 external extractor can/should only be checked with a force gauge connected to an adapter like this one...

...but I'm wondering why?

Does anybody know why the "shake test" (or maybe even the Jack Weigand dogbone adapter) shouldn't or can't be used to check the tension of a SW1911 external extractor?

P.S.: Here's a link to the whole FiringLine thread: http://thefiringline.com/forums/showthread.php?t=386404

Just a guess: the claw of the extractor is much 'taller' (too big, vertically), allowing much less up-down play.

The PXT extractor in my 9mm Para allows absolutely no play. The gun definitely doesn't have too much extractor tension.

I've seen pictures of Para's Power Extractor and know what you mean - it's a monster! But even though its claw is taller, I think a loaded round will still be shaken loose if the case rim opposite the extractor moves forward and off of the left hand breechface guide block. And after a little experimenting, shaking the slide vigorously in its horizontal or vertical planes won't get the round to drop out. But shaking in between - so the bullet heads in the direction of the open ejection port - does make the round drop free.

That's why I'm not too fond of the shake test. The tension assessment depends not only on how hard the slide is shaken but which direction it's shaken. Even the sights come into play. My wadcutter gun has high, sharp-edged front and rear sights which make it quite uncomfortable to grip tightly with a bare hand for a vigorous shake.

Wish I knew somebody with a SW1911 for a look-see.

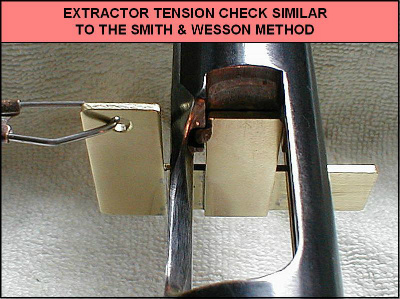

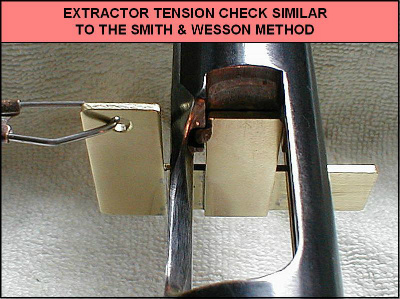

FWIW, with Petunia's internal extractor set to the average Weigand recommendation of 26 to 27oz using the Weigand method, a check using the S&W method sees a tension of about 8lbs.

That's 1lb above the top of the S&W range according to the thread on TheFiringLine - and twice the minimum! Maybe S&W external extractors do a better job of holding on to cases at lower tensions. Or maybe the acceptable tension in real life can vary a lot more than Weigand's 25 - 28oz range would indicate.

Oh goody. Now there's 4 different ways to check extractor tension.

Quote:

can/should only be checked with a force gauge connected to an adapter like

this one...

Do you pull that sideways? How does that measure extractor tension, or am I looking at this wrong?

Yes. It's pulled straight to the left in the photo with a force gauge via the fishing line snap-swivel shown. What gets measured is the sideways force the extractor exerts directly on the case rim (8 lbs by the S&W method) instead of the resulting force required to pull the case straight down and out from under the extractor (about 2 lbs by the Jack Weigand method).

Just a different way to skin the extractor tension cat. Besides, I just love making little things out of brass!

Interesting.

I can see the validity in measuring the sideways tension. Is the idea just to pull until the extractor begins to move? I assume any difference in breech face dimensions makes little difference in force--buried in the noise.

Interesting idea. I wonder why you couldn't simply attach the line to be pulled to the bottom of the plate which is slid up under the extractor? Still getting the sideways pressure, and would seem a lot simpler. Set the depth with a small cross piece.

As a gadget guy myself, I think I may have to make one that I can pull sideways from the bottom--at a set distance, and work up my own set of data.

Even though (as reported in the FiringLine thread) that's how S&W checks tension, I don't know if it's any better or worse than the Jack Weigand method: http://www.brownells.com/.aspx/lid=...ctor_Adjustment One possible flaw in the Weigand method might be that it measures how difficult it is to pull the case rim down and out from under the extractor. But the operation of the 1911 depends on the opposite - how hard it is for the case rim to move the extractor outboard and then slide up and underneath the extractor.

So with a different non-rotating adapter...

...the push-in force measured about 44 oz which is 12 oz more than when using Weigand's pull-out method. The additional 12 oz needed to move the extractor outboard about 0.010" to accept the case rim.

Course, you could flip that around, and measure the force to pull it up in there under the extractor - it would be easier with that device than with the Weigand device.

I've used the Weigand device (like I said, I am a gadget guy); it seemed to function fine.

I still find the full case shake to be adequate - but imprecise.

I think if the pistol is put together right, there is a very wide margin of acceptable tension, but I do prefer to have a method that gives more precise results. Not because it is needed, but because I am neurotic that way.

Quote:

'Course, you could flip that around, and measure the force to pull it up in

there under the extractor--it would be easier with that device than with the

Weigand device.

Only problem with that method is the coupling to the, say, trigger pull gauge, would likely be flexible and that flexibility might allow the adapter to roll its way up under the extractor.

I had a hard time keeping my home-made adapter...

...from rotating when pushing it up using my push-pull force gauge, and that saw the banjo-shaped adapter get made. In rotating, the case rim rolled on the extractor but slid up the opposite breechface guide block. In this, my experimenting gun, the case doesn't rotate when fed after firing. Whether pulled down or pushed up (and allowed to rotate), the required forces were virtually identical at about 32 oz. But with the non-rotating adapter on the force gauge the push force increased by 12 oz (almost 40%) to 44 oz. The increase due, I guess, to forcing the case rim to slide along both surfaces instead of just one - just like after firing.

I use the Weigand-like adapter and method because I don't check tensions often enough to get a good "feel" using the shake test. Besides, I've got a set of four push-pull force gauges with ranges of ½, 2, 4 & 15 pounds that need to earn their keep!

But I don't have a 1911 with an external extractor and started this thread mainly to find out if the shake test was a valid check for them. Both the FiringLine thread and Spyros' reply indicated it wasn't. For the S&W 1911 that leaves the first, S&W style, adapter shown and probably the Jack Weigand method. I underlined probably because all Weigand's website says about its use is:

Quote:

Brass, 2" long Works for most semi-auto pistols with exposed extractors and

open breech faces.

Note the "most". But I don't see why it wouldn't give a valid check provided an acceptable range of force values could be derived (see Post #4).