I posted about these in another thread and instead of hijacking that one with all the replies, I thought I'd start a new one. I also wanted to show what could be done on a Sieg X2 mini-mill with a little determination and imagination.

I recently finished a pair of Colt 1911 clones for myself and my father-in- law, who helped. I built the frames from aluminum and black anodized them, the slides from stainless steel, sights, MSH, and a few other parts completely on a Grizzly mini-mill that I converted to cnc. I bought the barrel and some of the other important parts that were easier or cheaper (or safer) to buy than to make. I made the grips on a cnc router I built a couple years ago, but made some fancier one's since these pics were taken. I will also do some fancy engraving on the slides when I decide what I want on there.

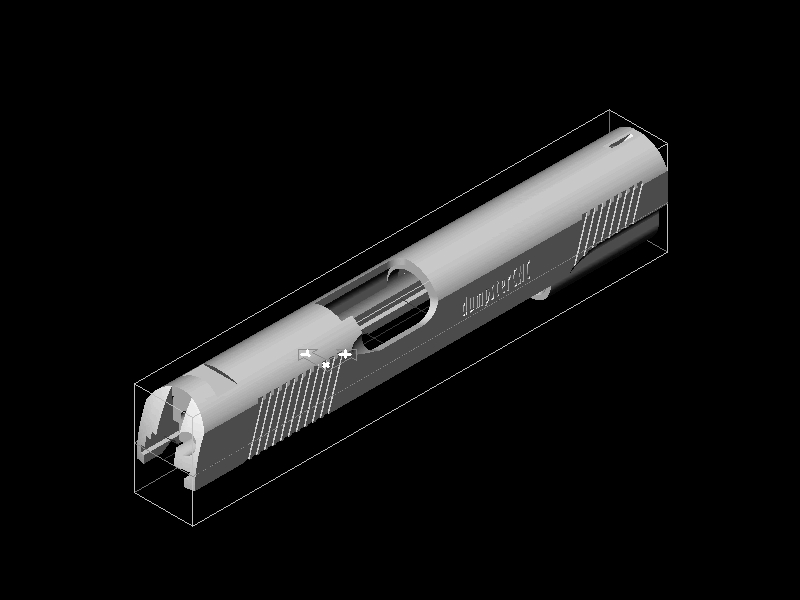

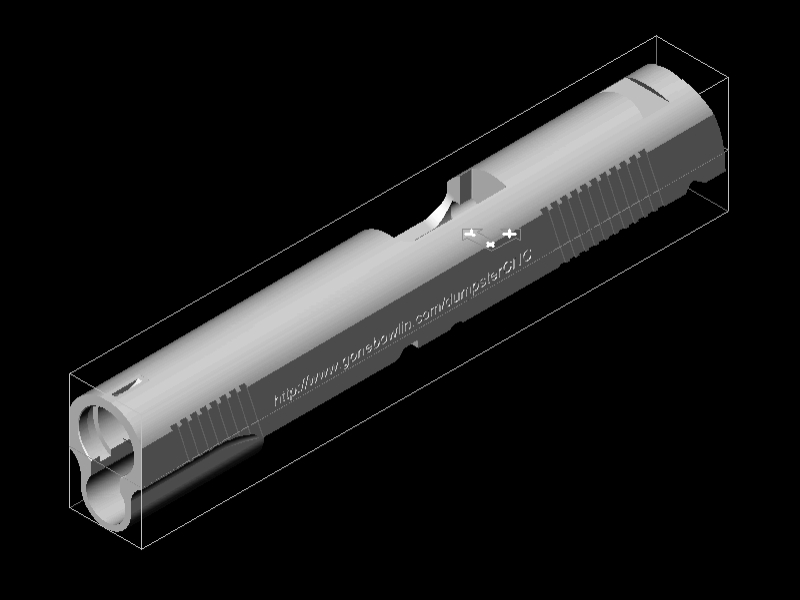

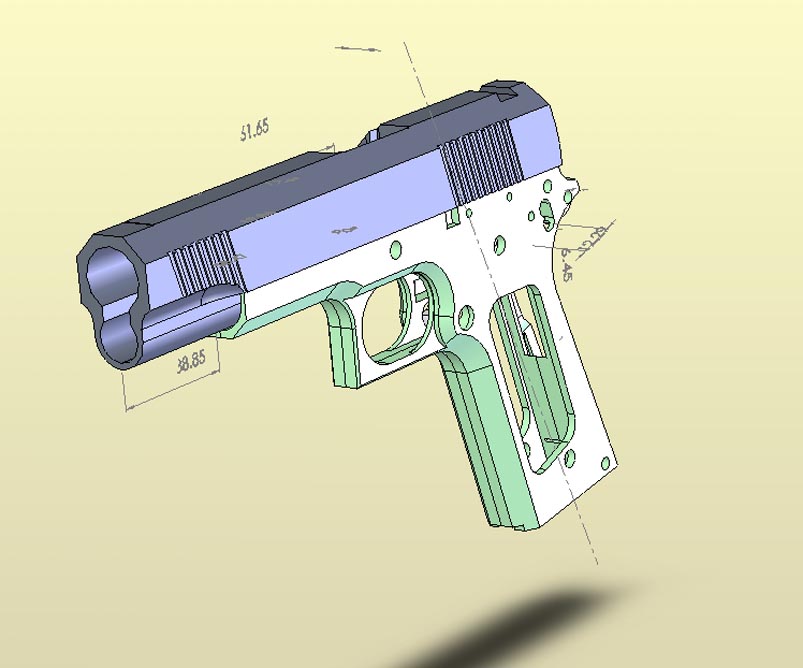

I found a solid model of the frame at cncgunsmithing.com and made a model of the slide myself.

We have over a hundred rounds through each of them and after the initial tuning, they function great. Anyone wishing to take on a project like this feel free to ask questions, I'll be glad to help if I can.

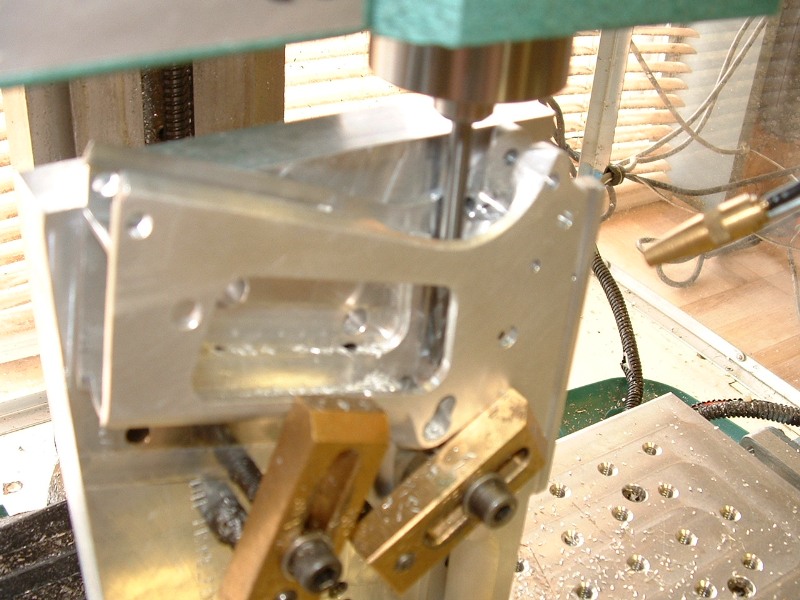

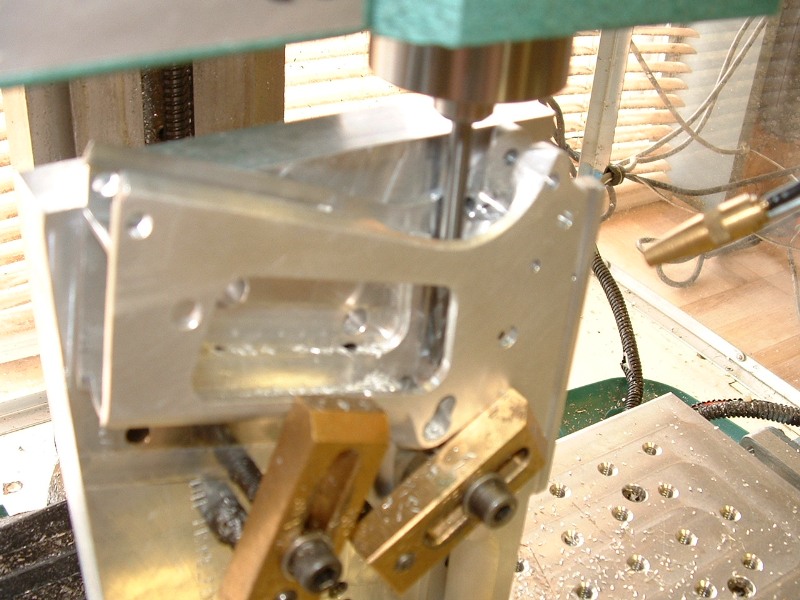

Here's a couple pics I took of the frame and slide while machining. The 3rd pic is with a new set of grips I made from Ebony.

How did you take Jasons solid model and covert it to g-code for your machine? I'm just getting started and would like to know how to do that. I'm using bobcad 21 and mach 3 but eventhough I can import the dxf files or model files, I can't make heads or tails out of them for cutting purposes. Do you chop them up into surfaces, unstitch them or what? Is there a short and not too detailed description for my tiny little mind?

You'll need to import the model into a cam program and program it from extracted geometry before posting out the g-code, I'm not familiar with Bobcad so not sure how that works. Those are some beautiful guns you built, I really like that race gun. I'm using my home-built router for the engraving to get the higher RPM, plus its more accurate than the mini-mill, no backlash which is very important for engraving small letters.

This gun was an undercutting nightmare! I used at least 10 different undercutters, the smallest being .187 dia x .03 thick for the mag release lock in the frame and the largest being 3" dia x .29 thick, not to mention the .625 dia x .19 thick x 5" long for the barrel locking lugs inside the slide. Fortunately I have access to a grinding shop since I had to make most of them.

Here's that 1911 slide model in .igs format for any of you guys that want it. I can't guarantee that it's perfect, but it's pretty danged close... I built mine from it and they came out great... and where else are you gonna find one?

I did have to do some serious hand filing on the inside to fit the barrel, but that was mainly due to the long endmill flexing. This model has the factory rounded top and standard sight cuts, front staked and rear dovetail. Be sure to get those blueprints from cncgunsmithing.com before starting this project.

When I first got the model of the frame and started this project, the first thing I wanted to do was to make it easier to build. Building it in 2 parts was something I dwelled on for quite awhile, splitting the model in half and going at it every way my little pea-brain could imagine. Screwing the 2 halves together was my first choice since welding or brazing is not really an option for me. I think it can be done with screws, the frame doesn't take any of the explosion, although every moving part on the gun gets punished pretty bad from the cycling, if you've ever shot one, you wonder how it stays together very long anyway.

The wall behind the mag well would be a problem, you'd have to add a tab at the botton below the MSH for a screw to keep it together there, or completely redesign the MSH. I just decided to build it in one piece, it's not really that hard if you have the means to make the cutters.

"There's a lot of snobbery in the 1911 market, sort of like jeans and athletic shoes; if a product doesn't fit the popular conception of fashion/"what's right" then it has an uphill battle to get and keep market share."

Tiger, you just said a mouthful and are completely right. That's why aluminum frames aren't catching on, who wants a gun made from aluminum??? (I did) I've read on some of the 1911 forums that the aluminum frame can crack after 6000 rounds or so... ok, but I'll never get close to that number and if it cracks, I'll make a new one.

I didn't think I had much of a point with this post, but I guess I do... If a frame "fails" that would generally mean that it developed a crack that may or may not prevent the gun from functioning, but we're not talking about blowing yourself up. I consider myself a pretty safety oriented guy and don't take chances. If you buy a "real" barrel (I did), this gun will not blow up. That very first shot I made after completing the guns (now called the "adreneline shot") was alot easier to make knowing that I didn't make the barrel. If you ignite a round in the magazine, you're in trouble regardless of how the frame was built, those wooden grips aren't there to protect your hands.

Ok, I forgot what my point was... oh yeah, we're DIY cnc'ers, try it, if it doesn't work, try something else.

I've always made my cutters of this sort on the lathe. Just chuck up oversize oil hardening tool steel and turn the shank and head to dimensions, then mill the teeth in the cutter head. Heat carefully with a torch played on the shank until the whole thing is at hardening temp, quench, then draw to useable hardness. Touch up the cutter teeth with diamond files and stones and yer good to go.

Tell us a little how you made the cutters!I use GibbsCAM licensed from work, not familiar with many others but I bet they work about the same. You extract geometry from the solids, extract an edge and it becomes a line then you write the program to cut that line. Programming an undercutter is the same as a regular endmill, just make sure you have clearance when plunging and pulling up the tool.

I made the cutters at work on a Cincinnati Monoset grinder. Like Tiger said, starting with standard endmills except the largest one. I hope to get a tool post grinder of some type for my mini-lathe eventually so I can make and sharpen tools at home.

could a frame and slide be made with a bevel cut design insted of all the curves.(i have a lama 1911 clone) i thought that it would look really cool with bevel cut slide and frame.

No reason not to that I can think of. That would probably look pretty good, make it look a little more modern. Its good to make a "one of a kind" by adding custom touches, I added the flat on top and custom fitted dovetail sights, it makes them stand out from others.

Like so?

I already have those 1911 files from cncguns. The trouble is i can't get the CAD file from cncguns.com of his to work in Solidworks, and the e-drawing isn't dimensioned. I would like to generate g-code from the model, but i am having problems in doing so.I hope this works