Joe C: What is going on in this picture?

I didn't want to muddy your thread, hope you dont mind me borrowing your picture, I was just curious about the notch your milling here.

Not Joe... but he is milling a ramp onto the rail for the head of the disconnector to ease onto the rail rather than be forced onto it over a squarish corner.

That's what I was thinking but why so wide? Is there an optimal angle? Is there certain situations where this cut is undesirable, or maybe more desirable? Are there features to this cut that aren't readily apparent in the pictures, such as chamfers or radii? I need details baby, details!

Donkey Hunter, details cost you in this life...

In all seriousness this is a cut that my mentor Bob Marvel invented many many years ago. It was one of his many secrets until just about two years ago when it was shared with Jerry Keefer who first shared it on here.

What Mgraff said is correct. It is an angle cut on the disconnector rail to allow the slide to go forward without stalling on the disconnector.

I use two different cutters for this operation depending on the caliber of gun. On the .45 I use a wider one than the 9mm/.38super/.40 because the rail is wider on the .45acp typically. Yes there is a specific angle that Bob and I prefer but I know that Jerry used a different angle for a while as he did not have the jig with the original angle until I sent him one... he is just that smart.

Yes, there are several features to this cut that you don't see here as this is just the initial machining of the slot. They are done at a later stage to finish the process after machining. And yes there are certain situations where this is desired, as in any time I build or rebuild a 1911.

This is a feature that greatly enhances reliability and accuracy on a 1911 style pistol.

Accuracy?

I can see that the ramp would allow the slide to cycle easier, but how does that affect accuracy?

Wouldn't beveling the edge of the rail and/or the tip of the disco accomplish the same thing?

Quote:

Wouldn't beveling the edge of the rail and/or the tip of the disconnector

accomplish the same thing?

I'm not answering for Joe but since I have done this trick for a while I'll explain my experience with it.

Even if you bevel the disconnector, you will still feel the resistance when it strikes the breach face as the slide cycles forward. This, although part of the original design, is rather hard on the disconnector. It causes wear that is almost cured with this cut. After a while without the bevel, your reset changes due to the length of the disconnector constantly changing length (shortening) over time.

This little detail provides a consistent reset and it also provides a much smoother action. The slide feels like it's on bearings throughout the complete cycle.

I'm sure Joe has his secrets for depth and angle which I'll let him share if wants to. For me, my cut is not as pronounced as his. As far as accuracy, I'm sure it has to do with his proprietary angle and depth.

Bob invented that? I've been playing around with that modification for years.

Could you clarify what you mean by 'the reset changes' after a while? And how would this affect accuracy?

Jim Boland did this to every racegun he ever built! (circa 1985-95)

It was so lightly sprung comp guns had 100% function and smoother feeding. It also helped disconnector reset.

Wow, so many posts so little time... I'll do my best...

@Armen, anytime you can improve reliability you have a chance to improve accuracy. In this case, by allowing the slide to travel forward smoothly instead of stalling against the disconnector you are allowing the rounds to feed into the chamber in the same fashion each time. Now, if everything else is correct, chamber, extractor tension and placement, etc, the gun is will be more accurate because there is no longer that particular interruption in feeding the round from the mag into the chamber.

@JMB1911, the answer to your question sir is no. WarriorSteel1 did a good a job of explaining I think. Several companies out there have tried to do it the way you asked about... it does not accomplish the same thing. It just beats the disco up and causes the trigger pull to suffer.

@Dave, Well, unless you have been doing it since about the mid 80's, I would say you were not the first...

@mamba911, it was my understanding that Jim got this idea from Bob somewhere in that time frame after seeing it on one of Bob's guns... I was led to believe they were friends years ago but have no idea.

Joe, so basically you're easing the disconnector onto the flat instead of slamming it into the breechface, very astute.Smoother action, longer life. Mr. Marvel was a genius.

My question; Doesn't this delay trigger reset?

Feeding Impact?

Joe C, I'm just wondering if this cut could cause feed problems since there is less metal to catch the round as the slide returns to battery? I suspect that is part of the secret - how to do the cut without creating feed problems?

Don't know much about how or why, but I got two firearms with that cut in the slide. Slickern a three year old's snot on a glass patio door!

Quote:

Joe C, I'm just wondering if this cut could cause feed problems since there

is less metal to catch the round as the slide returns to battery? I suspect

that is part of the secret - how to do the cut without creating feed

problems?

No sir it actually aids in better feeding. Think of it this way if you will... try pushing a ball along a straight line on the ground with one stick... now, get two sticks and put one stick in each hand and push that ball down the line...

Using hand tools (files and stones) I made a ramp on my slide simmilar to the one in the picture. I radiused the lead edge and polished the whole mess. I also removed the disco and stoned and polished the top of it. Definitely feel a difference in the smoothness of the slide action as I work it back and forth.

I checked to make sure I didn't make the trough too wide by blueing and working the slide and looking for marks made by the disconnector. Looks like a winner! Can't wait to shoot it and see how feels.

I'm just wondering how would machining the groove on the slide really help in better feeding, when you fire the 1911 and the slide cycles to chamber a new load doesn't the disconnector stay down by the frame? it does not even stick out.

Quote:

I'm just wondering how would machining the groove on the slide really help

in better feeding, when you fire the 1911 and the slide cycles to chamber a

new load doesn't the disconnector stay down by the frame? it does not even

stick out.

Ransom Rest testing soon teaches us, that the first round out of the magazine, from lock back, is usually not in the group... Why, normally it does not chamber with the same force as the rounds fed while firing. The disconnector has some effect, but not all on this process.

When competing in a 2700 bullseye match, you will fire 18 targets with your .45

Six of those are at 50 yards. Most knowledgeable shooters will only drop the slide on six magazines, via reloading on the fourth round fired, skipping a lock back. You can load ten at the 50 yardline, but ten rounds places more upward pressure on the slide than a magazine loaded with five. Not consistant, Not good. All in an effort to minimize the first loaded round syndrome... By cutting the slot in the slide, we are taking the disconnector as far out of the equation as possible. You will drop the slide 24 times at the 25 yard line... but the mechanical accuracy edge needed at 25yds. is no where near that of the 50 yd line.

Still, I don't think it has anything to do with the disconnector, as I said: when you squeeze the trigger then the gun goes bang, then the slide cycles to chamber another round, doesn't the disconnector stays down until you release the trigger again.

I have pondered this mod since the first picture appeared.

While I understand the theory behind it, I cant get my head around the fact that regardless whether you use your mod or the standard bevel, how does the disconnector factor in when the barrel is still loose (unlocked), and the magazine has some play?

I would think the magazine and barrel would be more useful areas of improvement than the disconnector "snick".

You still have over half the slides travel to go as the cartridge is feeding and bumping into the chamber, at which point the disconnector is only moving when the gun goes fully into battery(reset).

I am genuinely interested in your responses.

Joe, I read your response about the two sticks and I would repectfully counter that pushing a ball down an alley with two sticks is not the same as pushing the same ball down the alley with a paddle the width of the alley

Quote:

Still, I don't think it has anything to do with the disconnector, as I

said: when you squeeze the trigger then the gun goes bang, then the slide

cycles to chamber another round, doesn't the disconnector stays down until you

release the trigger again.

Yes, speed, but, it's not about the firing cycle. It's about the first round into the chamber from lock back. The disconnector is standing tall at this time...

Wouldn't holding the trigger depressed while locking and loading accomplish the same thing?

I am not at all familiar with BE rules, (my caffeine/nicotine habit rules out BE for me, picture a mongoose on crack) but the BE guys I knew always did that anyways.

I think maybe the impression is that this little slot magically makes a gun a super bullseye contender. It is but one of many modifications in an effort to glean that last micro bit of precision for the shooter. Yes, I agree with you that the barrel and magazine play a big part, and I do make a major effort to minimize their effect. Magazine flop is big on the older Colts, but those are dying off, as the newer frames become more predominate. In the previous post I tried explain the first round out of the magazine. It definately helps.. It's not a perfect cure, but I can see an improvement.

The slot has zero impact on cartridge base/breechface contact. So the sticks, paddles, and tow trucks cancel out. The cartridge base is setting very close to .180 above the frame bed. Most of the slots are only .050/.060 in depth. So the breechface still makes the same contact to strip the round from the magazine. I use a long gradual angle, Joey and Bob use one that is shorter.

When the command to load is given, and the slide release is dropped, the disconnector is easily cammed down by the slot, not jammed forward, and offers almost zero resistance to the slide going forward, almost identical to the firing cycle... consistancy wins bullseye match.

@ Bill, I have seen a number of the guns that Bob did this to early during his "development" process. Most all of them were filed into the slide. So, can it be done? Yes. How easy is it? Well, I reckon that would depend on how good you are with a file... Looks like another poster on here has already tired it. I can say this. When done the way Bob and I do it you need to slightly modify the top sides of the disconnector to get the full effect. Failure to do this can cause damage to the disconnector nose.

@ the rest of you guys, Jerry is correct about the first round feeding. However, on the five guns I checked here tonight that do not have the cut, on all five the disconnector sticks up above the frame during cycling when the slide comes fully back regardless of whether the trigger was forward or kept back. So, to me that means that as the gun is firing the disconnector can cause the slide to stall however minutely depending on the spring pressure of the disco. Case in point was the SS Springer I rebuilt recently that many of you saw pics of on here. When it came in the pressure was so bad that it would stall and fail to fully close during firing with light wad loads (although I will admit that the 7lb recoil spring that was in it probably didn't help!)

Is it enough to cause an accuracy issue?

Ransom rest testing has shown the answer to be yes. As the slide is coming forward to feed the next round in the magazine if it stalls on the disconnector it causes a slight interruption in the feeding cycle of the gun thus causing the round to feed differently into the chamber, this causes diminished accuracy. Now, if we are talking about your average gun at 50 yards, probably no big deal. However, if we are talking about making a .45ACP shoot sub 1.5" or a 9mm/.38 Super shoot sub 1.00" for 10 shots at 50 yards it can be the difference of as much as .250". That's a lot to people like Jerry and myself.

Does a guy have to have it? No. Do people that have it notice a difference? Yes they do, both in accuracy and the way the gun feels in their hand while shooting it. And again, to just make sure, I checked five guns of several makers tonight before replying to your posts to reassure myself that the the disconnector does indeed come above the frame and hit the slide during cycling whether you hold the trigger back while cycling or whether you let it go. In either case you can feel the disconnector hit the front edge of the rail on an unmodified gun.

Now to you Chuck Warner... why do you always make me think so hard? Always challenging me to get better with my reasoning and abilities without being condescending aren't you... thanks... The round does indeed stick slightly above the cut (at least the way I do it) while in the magazine. But the cut does, in my opinion, cause the gun to feed more reliably because the slide now never encounters the slight resistance of the disconnector as it is coming forward to feed the round. Now, I'll not abandon my "stick" theory regarding this until I have more time to study it. But, I guess the best way I can describe it is it allows for less interrupted feeding of the round.

What this can do for someone like you that typically builds "combat/carry" type guns is in my opinion wonderful. It allows you to have more reset tension if desired due to sand, dirt, etc. that may be encountered without the risk of the slide stalling on the disconnector. More consistent feeding, better reliability, better accuracy... might be the difference between coming home from the gas station or not...

I just checked my Kimber TLEII and it has some resistance when the slide hits the disconnector, even when trigger is depressed, as it would during the firing cycle. It is not as much as when dropping slide on fresh magazine, but the "snick" and resistance is there. I am pretty handy with a file, think I will do this modification.

A side benefit of this modification that comes to mind that I have not seen anyone expound upon is this: it seems that this modification would give the next round in the magazine a bit more time to get in front of the slide for proper feeding, in other words, the next round in magazine would have a bit of a "head start" in rising to the magazine feed lips, as it would start rising when the rim of case enters the cut, instead of having to wait until the square edge of slide pases by. Theoretically at least, this should also enhance reliability, if I am thinking correctly.

Quote:

When the command to load is given, and the slide release is dropped, the

disconnector is easily cammed down by the slot, not jammed forward, and offers

almost zero resistance to the slide going forward, almost identical to the

firing cycle... consistancy wins bullseye match.

As a competitive bullseye shooter, in slow fire @ 50yds, I always reset the sear after loading the first round and then reload with 5 after the 4th shot.

Today, when I read this post (you are a very good communicator) the light came on!

To the bullseye shooter the disconnector reset is everything! I can tell the difference between the first round reset and the other 9. Now I know why! On my 1911 (without the ramp cut in the slide) the act of closing the slide, the jarring of the disconnector and the play in the disconnector hole, slide-frame fit, the contact of the disconnector and trigger bow etc. all figure into how the disconnetor and sear feet re-engage which effects the "feel" of the trigger press (especially if it's a roll trigger).

I just did this with one of my slides. I scribed where the shell case sits and measured how high the disconnector is. Then I filed a chamfer just a little above the disconnector so the disconnector is a tad on the ramp of the slide when its at its point of entry. In running the slide before and after there is a different in the force to make the slide go over the disconnector. I made a very smooth pass with a fine file but I may polish it with simi chrome polish to smooth it out even more. We used Simichrome polish in plastic injection molds to remove the machining marks, besides on motorcycles to bring back the life on chrome and alumimum finishes too. Its a very, very fine polishing compound. It will make the mating surfaces have a break in smoothness ahead of time to cut down on the wearing in part of the process. I also lube that area with moly too.

I also use the Simichrome polish on stainless steel finishes on guns too to bring them back to there orginal condition too.

Quote:

Jerry if I may ask a very benign question... if someone is NOT a bullseye

shooter, like myself, but instead practices the art of combat shooting, will

these kinds of mods make any difference in that arena?

I don't think you would see benefit from them at all... Combat shooting is a different game/discipline, with different equipment requirements... Most of the readers and other builders on this forum fit into your catagory, or the custom gun group, but I enjoy the interaction of share and compare. Many of these questions/answers provoke thought which promotes learning. An old army Sgt. once told me, "you can learn from a recruit", because they force you to think.

Sorry for my delay here guys... it's been a long day. Anyways, as for machining the slot in SS, I have found no problems with that at all. I do it the same as with carbon. Same cutters, same speeds, works fine.

As to a radius cornered cutter, have you SEEN what those cost! Just kidding. While I know that a radius cut is typically stronger and I think someone before me mentioned this it does not seem to be something that is necessary considering where the cut is made.

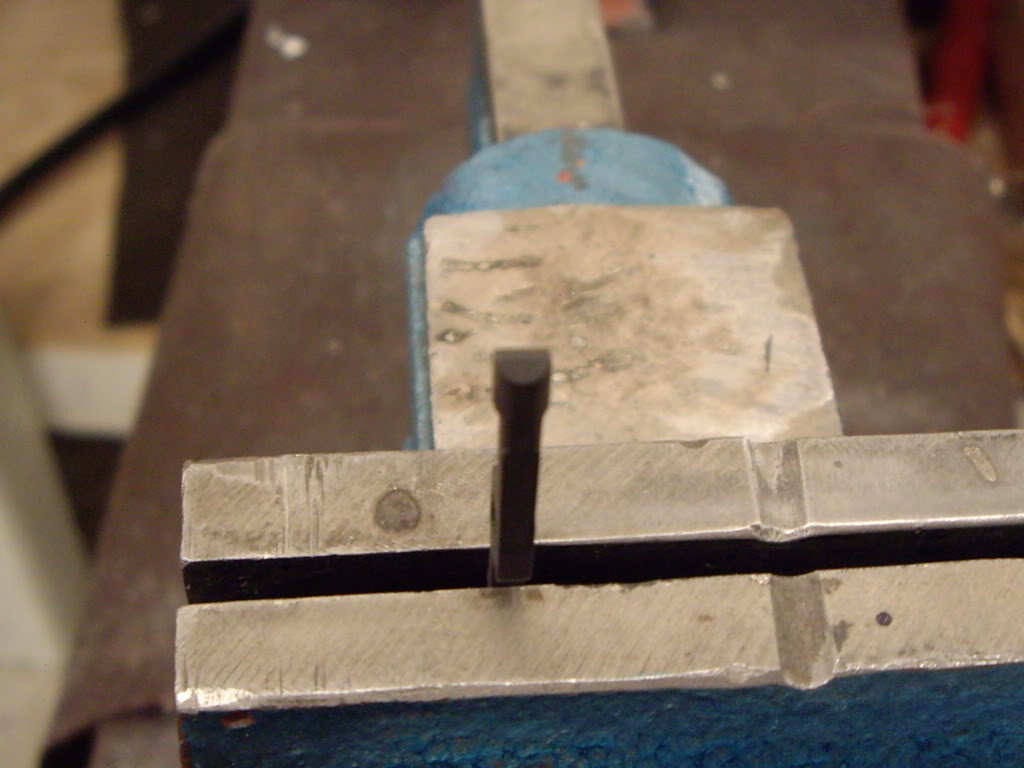

And finally, here are two pics for you of disconnectors. The first is a standard unaltered one as I'm sure most of you are familiar with:

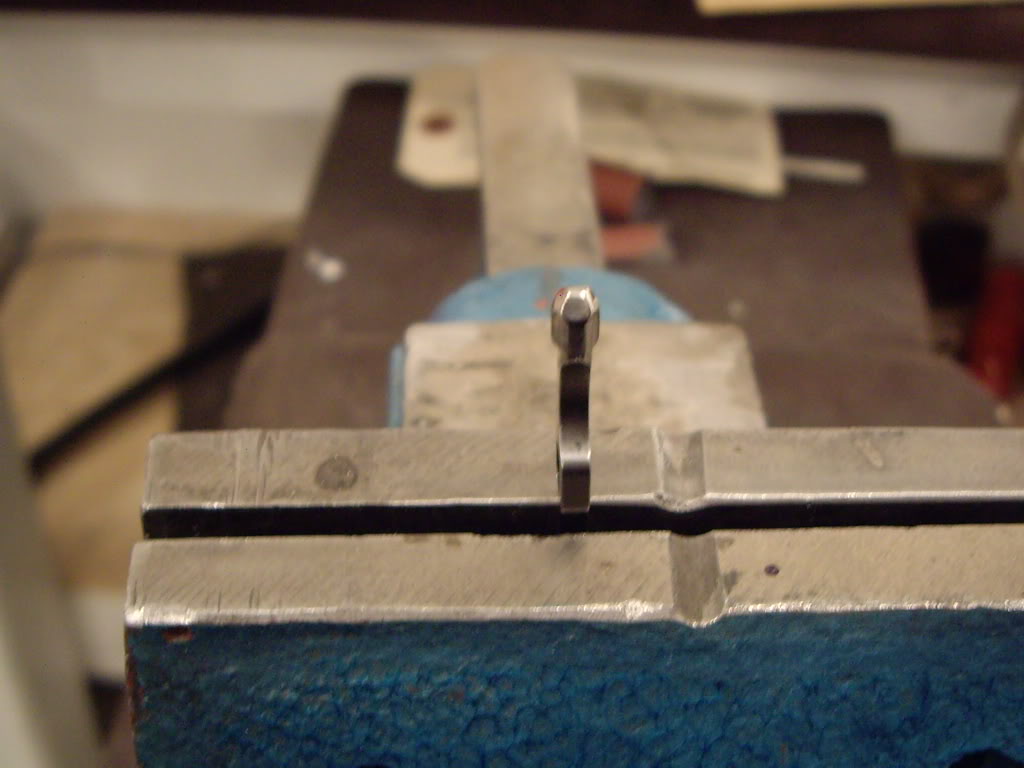

The second is one that was modified for the cut on a 9mm. The slot cut on the 9mm/.38 Super/.40 is narrower than the .45 for reasons I listed in a previous post. So, on a .45 it takes much less relief on the top sides of the disconnector that on this one for the 9mm.

I am by no means an expert on 1911's, but I have built one from a casting. While this being my first I have no other to compare to other than those shown on this great site. I've done quite a few modifications found here including this one, however I haven't seen it until now. It is nice to know that I didn't do something that far out there.

I was having a bit of trouble with the slide sticking back with the trigger pulled and held. I narrowed it down to the disconnector. Without knowing the "proper" way of dealing with this I added a small chamfer to the bottom of the slide in the same spot with a bull nose endmill. I haven't had it stick since and it cycles wonderfully. Whether I did it for the same reasons as above or not, I have done it and it has helped me with my issue greatly.

I can't say for sure if it has helped accuracy since I haven't even put a round thru her yet!

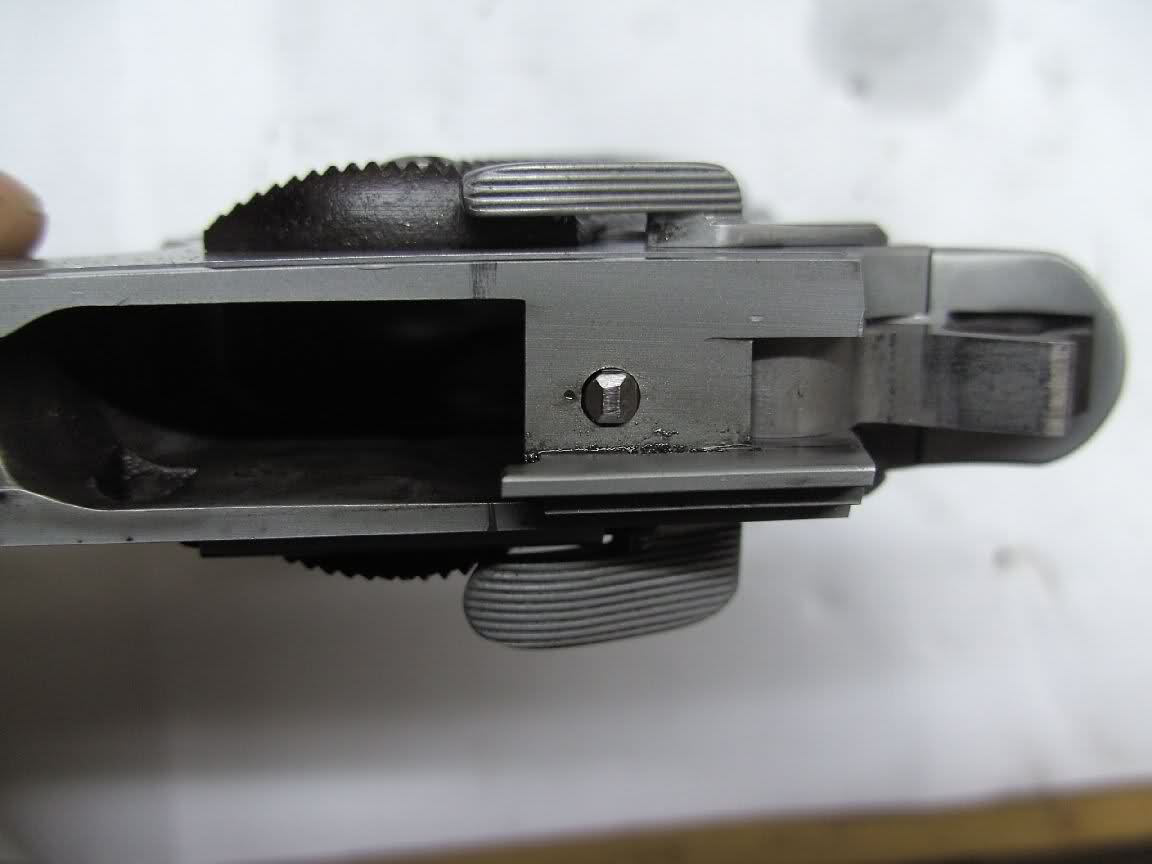

Today I stripped my Les Baer and you know what, my disconnector looks the same as the one in Joe C pictures.

Baer uses some kind of angle on the "bottom of the breechface"

and the Bear disconnector

These cuts are similar like the cuts from Joe C, think the cut on the Bear slide less effective but not that expensive for a semi custom...

If you cycle by hand you still feel the slide hitting the disconnector...

Yes, that is typical work... notice the roughness of the disconnector nose. Those file marks on the nose are not really a good thing. But then I just like things a certain way and I'm not building hundreds of guns at a time (not that numbers are really an excuse). If I were you I would be cleaning up the nose just a pinch.

The bevel on the front of the disconnector rail... well, I don't really know why guys do that because it doesn't really do anything to aid in feeding or smoothness of the gun in my opinion. As you said in your post you can still feel the disconnector hitting the rail during cycling. STI does the same thing to one degree or another... but I have seen it on Baer guns for some time now.

The bevel on the disconnector rail corner to breech face is specified to be .020" at 45deg and is for the same purpose as a door latch striker plate. You will also notice that if you dry fire and hold the trigger back, as will be the case in live fire, and pull the slide back you will see that the disconnector is down and barely rubs. Your Baer is fine.

Last week I had an old Thompson slide in my hands, there was no cut on the slide...

I saw a picture on the Belgians STI distributeur site of the stock STI disconector and there are no 'side cuts'... just a straight edge like in a previous picture

I guess it's fine if you don't mind file marks and uneven filing on the disconnector nose... As far as that bevel being "specified"... well, it wasn't done on Colt #305 made in 1912 that I had in my mits for a couple of weeks so I'm curious as to when that cut became "specified" and by whom...

That's true and an important point to learning. Here's a couple of disconnectors, the ball head type, and the bevel can be seen.

And this CMC shows it also.