I'm having a problem that's driving me nut so maybe it can drive you nuts to. I got a 1911 70 Series Remington-Rand on an Essex frame, internals are stock. Fired good, shot about 100rds though it no problems. The problem I'm having is that I can cock the hammer by hand with no problems and fire it no problems but when I cock the hammer with the slide or with the slide off and pressing down on the disconnetor the hammer with not fire. It just locks up and I can't get the trigger to squeeze and the disconnector stays stuck down. I have to take off the main spring housing to get the hammer to release.

Right now I have the slide off and grip safety off so I can see what's going on. It still locks but with the grip safety off I can over cock the hammer and get the hammer to unlock and get the disconnector to pop up and then fire.

I've changed out the sear, diconnector, hammer, sear spring and so on and tried the old ones with the same problem. The only thing I haven't tried out yet is changing out the trigger and mag release for the stock ones. I'm thinking that the hoop on the trigger may be longer and causing the disconnector to hang up.

Obviously the disconnector should go up and down as you push it at the top of the frame. If the sear spring center leaf is too long it will ride to the top of the wedge and hold it down. The correct length of the center leaf is in relation to the wedge to be just below center of the wedge when the disconnector is up and just above the center when it's down, even with the frame. The wedge surface must be smooth and flat without grooves or wear marks. The tip of the center leaf should have a bevel on it's bottom corner that contacts the wedge and be polished.

Remove the slide and hammer, then slide the MSH back in to hold the sear spring in its proper place.

When you push down on the disconnector, does it go down smoothly or roughly?

When you release the disconnector, does it pop up all by itself?

Does the aft end of the trigger bow (the stirrup) extend back past the mag well partition when the trigger is fully forward? If so, by how much?

I don't know if this is the cause of your problem, but I had this exact issue a few years ago. It drove me nuts. Turns out the trigger bow was out of spec -too long. Seems strange that such a simple issue led to so much frustration at the time (I was new to the 1911). It'd be easy to find a trigger with a shorter bow and see if it makes a difference.

Quote:

It'd be easy to find a trigger with a shorter bow and see if it makes a

difference.

Or, maybe first root around in the curved forward part of the trigger channel with a screwdriver to see if there's any crud keeping the trigger from going all the way forward.

Then too, this particular trigger bow might have mis-adjusted pretravel tabs doing the same thing - maybe?

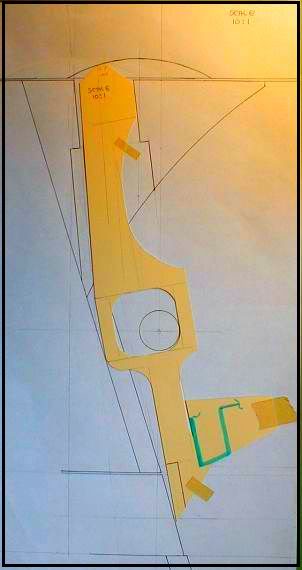

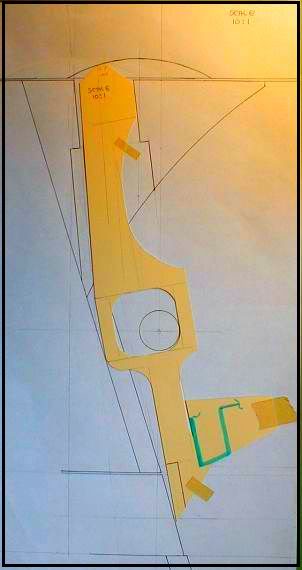

FWIW, here's what a mid-spec GI 1911 would look like with the disconnector up:

While you've got it apart (again) check to make sure interference between the sear pin and aft surface of the square hole in the disconnector isn't keeping the disconnector from popping up. Shown here:

I usually just polish that surface as it's kind of hard to tell if there's any interference once the parts are in the frame.

Whether or not there's any contact there depends mostly on the length of the trigger bow.

Got the chance to work on the gun and here's where I'm at. I completely checked over the trigger and that's not the problem. I have the gun down to the trigger, shear, disconnector, shear spring, and main spring housing. When I press down on the disconnector it sticks and doesn't pop back up. I checked the shear spring disconnector leaf and it has no burs and has the correct bevel. I've found that when I press down on the disconnector and it sticks that if I very lightly press on the top of the sear that catches the hammer it allows the disconnector to pop back up ever time.

Where did you get the sear spring? I have had two pistols that exhibited an odd behavior. They would shoot fine for one round. Then the next time I pulled the trigger, all I'd get was a "click." Pull the trigger again, and it would fire. Pull the trigger again... "click."

The click was the disconnector resetting. It should reset by itself, but something was slightly out-of-spec and it took the movement of the trigger to knock it loose and make it move. The culprit was a sear spring with the middle leaf (the one that presses on the disconnector) that was too long. Instead of resting about at the mid-point of the angled "wedge" portion of the disconnector, it was making contact very near the top, so it was pushing the disconnector more forward than up.

Solution: genuine Colt disconnectors from Brownells cured both pistols' problem.

I assembled a Ceiner .22 / AR Sales LW GM pistol and had the exact same problem. The disconnector would stick. Drove me back and forth.

Dropped in a stock Colt trigger in place of the Greider and it worked fine.

I do think that some triggers may have a slightly longer bow. But I think that the AR Sales frame was a second, the finish was rough.

It would only take a few thousandths of an inch to do that too, and maybe the trigger slots were short a few thousandths.

Although it's not a very good pic, here's about how the center leaf of the sear spring should sit on the disconnector when the disconnector is up:To see if the sear is preventing the disconnector from resetting (popping up) remove the sear and see if it still sticks down.

Ya know that makes me want to ask it the trigger has any pre-travel and enough pre-travel. If it has take up tabs and they are over adjusted, well it won't re-set.

The trigger resets every time. From that picture my sear spring seems a lot higher on the disconnector but I don't have the gun in front of me right now to really see.

While the trigger may reset (go fully forward) every time, it needs to go forward enough to also allow the disconnector to reset. That's was Log Man was asking/wondering.

Trigger pretravel is the distance the trigger moves aftward before it pushes the bottom of the disconnector (its paddle) into contact with the forward surfaces of the sear's legs. This with the disconnector reset (up).

Check your trigger's pretravel with the hammer fully cocked and the disconnector reset (up) by measuring how far back the trigger moves before it encounters its first amount of significant resistance - just as it pushes the disconnector paddle against the sear legs.

[Edited: Refer to the pic in Post #6. Your pretravel should be about 0.035"]

Also note that Niemi's photo (he said) is with the disconnector in the UP position. I would like to see a similar photo of your pistol, with the disconnector in the DOWN position.

Just double-checked it. Yup, it's up!

Not the greatest pic, however - lotsa glare.

OK the pic was a lot of help. What I found is the disconnector leaf was about twice the height as in the pic. I started by removing the sear and putting just the disconnector in. When I do this the spring sits at the right height and the disconnector works beautiful. Once I put the sear back in though the spring sits twice as high and the disconnector won't reset. Also I don't know if this is wrong but when I push the disconnector down the sear springs pushes the sear ahead of the disconnector and doesn't allow the disconnector to reset. I didn't know if this is a problem or was just because the hammer isn't in and doesn't stop the sear.

Quote:

OK the pic was a lot of help. What I found is the disconnector leaf was

about twice the height as in the pic. I started by removing the sear and

putting just the disconnector in. When I do this the spring sits at the right

height and the disconnector works beautiful. Once I put the sear back in

though the spring sits twice as high and the disconnector won't reset.

This sounds to me like the middle leaf needs to be bent forward or the left leaf bent back a little. They both need to exert tension on their designated part, 1# of tension on each leaf when both sear and disconnector are installed would be a place to start and get function back. Realize that during normal function the leafs are always in contact and under tension with their respective parts.

Quote:

Also I don't know if this is wrong but when I push the disconnector down

the sear springs pushes the sear ahead of the disconnector and doesn't allow

the disconnector to reset. I didn't know if this is a problem or was just

because the hammer isn't in and doesn't stop the sear.

This is simply as you say due to the hammer not being in place to keep the sear from going too far and what's happening in this regard is normal.

Quote:

OK the pic was a lot of help. What I found is the disconnector leaf was

about twice the height as in the pic. I started by removing the sear and

putting just the disconnector in. When I do this the spring sits at the right

height and the disconnector works beautiful. Once I put the sear back in

though the spring sits twice as high and the disconnector won't reset.

Forgot to mention that when doing this with the sear removed, the sear pin does need to be installed.

Without the sear pin and without the sear, the disconnector can move up much higher than normal.

Was the sear pin installed when you made the observation in the second sentence?

If it wasn't, please put it in and recheck. Sorry for the inconvenience.

And here's a better pic showing the sear spring center leaf's position on the disconnector wedge:The differences between this and the previous pic are: this is a new Colt sear spring; slide is installed in the battery position which holds the disconnector down a little bit; sear & hammer removed for clarity.

Quote:

Forgot to mention that when doing this with the sear removed, the sear pin

does need to be installed.

Without the sear pin and without the sear, the disconnector can move up much higher than normal.

Was the sear pin installed when you made the observation in the second sentence?

If it wasn't, please put it in and recheck. Sorry for the inconvenience.

The sear pin was installed

Quote:

This sounds to me like the middle leaf needs to be bent forward or the left

leaf bent back a little. They both need to exert tension on their designated

part, 1# of tension on each leaf when both sear and disconnector are installed

would be a place to start and get function back. Realize that during normal

function the leafs are always in contact and under tension with their

respective parts.

This would make sense to me, looks like the sear is putting to much pressure on the disconnector not allowing it to reset.

Quote:

...looks like the sear is putting to much pressure on the disconnector not

allowing it to reset.

The sear doesn't put pressure on the diconnector. It's the other way around. The disconnector puts aftward pressure on the sear while the trigger's being pulled to fire the gun.

The disconnector also applies upward pressure to the sear under the following cirmcustance.

After firing when the hammer gets cocked and while the trigger is still pulled back, the disco paddle's "ears" are under the tips of the sear legs and the center leaf of the sear spring pushes the ears up against the bottom ends of the legs. This holds the disconnector down and prevents it from resetting until the trigger is released. Releasing the trigger allows the center leaf of the sear spring to move the disco paddle ears forward of the sear legs, allowing it to move up and reset.

Recommend you remove the thumb safety and grip safety and observe the operation of these parts. Knowing how they interact will help us help you get your gun running.

I understand that. I was referring to were they come in contact that they are pressing to hard together casing to much friction for them to slide.

OK, good point. Either too much pressure or perhaps the correct amount of pressure but the contacting surfaces are too rough and don't allow them to slide easily.

Take your hard Arkansas and stone them smooth with no sharp corners first. Whether the pressure's too much or too little, they've still got to slide freely for an easy, sure reset when the trigger's released.