I'm getting D shaped brass out of my GI. I have a working theory. Any opinions please?

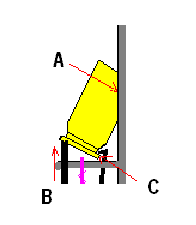

The brass is hitting the ejection port hard enough to flatten it into a D shape (point A). I think it is hitting the ejection port because it left a good build up of brass on the inside lip of the port (point A). The extractor is putting a pretty deep scratch in the rim of the cartridge shell. Point C.

So I'm thinking that the extractor (point B) pushes on the spent cartridge. But the new extractor is sharp and grabs the rim (point C), the cartridge is hung on the extractor and pivots at point C and the ejector drives the cartridge into the side of the slide at point A (I don't have a lowered ejection port).

What do you guys think?

Background:

So I have a GI spec pistol without lowered ejection port. The pistol feeds

fine but the ejection is not consistent. The last round out of the clip's

brass comes straight back and will put a nice dent in my forehead. The brass

also likes to go straight up, bounce off the ceiling and peg me on top of my

head. I guess If I had a thicker head of hare this wouldn't be a problem. Or

maybe I should wear a hat?

What you're experiencing is commonplace with GI-spec 1911s, and has been since the very beginning. The small GI ejection port is barely large enough to ensure good ejection, and the brass often hits on the way out. If it doesn't hit the edge of the port it invariably gets flipped end over end, and gets dinged as it smacks the outside of the slide during recoil. Lowering and flaring the ejection port is the most common cure for this issue. You *could" play around with the extractor hook shape & tension, and possibly the ejector shape and angle as well to help "train" your pistol to always throw the spent brass clear without hitting on the way out. However altering the ejection port is the faster, simpler, and more sure means of correcting the problem.

I don't know why I get such a kick out of looking at brass marks.

But, give this photo a look please. Look how deep a chunk the extractor removed from the ring. It's deep, and the D shape, it's just a lot more deformation then I've seen out of the 1945 GI I shoot, its interesting to me.

That's nothing compared to the brass that came out of my Colt GI back in the late 80's. Where your brass is flattened, mine would crease the brass and put a big V in the brass.

I took it back to the shop I bought it from, since they were also known for their smith work, and they lowered the ejection port and re-blued the slide. That fixed the problem for me.

I agree with DSK, That would be the fastest and easiest way to solve your ejection problems and add some reliability to your pistol.

I don't doubt you guys, I came to the same conclusion. I got the stripped down pistol so I could figure out all the mods a really needed.

But getting the slide machined is not in the near future. Any advice on the type of things I could do to mitigate the issue. we reload, and my brass is getting a bit chewed up?

I have a year old Colt Series 70 reissue (non-lowered port) that dented the brass mouth similar to yours. When I converted to 460 Rowland, the dents were like yours or worse. I just removed some material on the inside of the slide and the problem went away. I could have fiddled with the extractor as well, but the brass goes mostly straight up, perhaps 1:00 o'clock, and this is handy with the Rowland, as the brass does not go far. As to the chunk out of the rim, I would say that you other issues going on as well.

460 must be rad.

The chunk on the rim is related to the smashed mouth of the brass. Can't have one without the other. In my mind the extractor and/or the eject has an issue which is throwing the brass to the right. With a lowered port they just wouldn't be running into a wall, but they would be flying out the side.

A heavy recoil spring would reduce the speed that the ejector hits the brass. which might change the dynamics of things.

The extractor is obviously getting abused. Its stronger then the brass, but each chuck it takes out of a rim has to be either wearing it down or bending it.

You can 'machine' the ejection port with a couple of sharp files. Does your pistol have an extended ejector? Ejectors are cheap and you can play with the angles on them to get a cleaner ejection.

Sevenl4 has the solution that I would likley try first, after checking the extractor. As you seem to understand the geometry of things, it is pretty easy to play with the nose of the ejector to tweak the directions of things. I would certainly first make sure the extractor is shaped and tensioned properly. You would be amazed at what a little bit of filing does for things. And this assumes you have or can put in an extended ejector. If you ejector is milspec style, things will be harder, as I have tried the geometry adjustments on a standard ejector with little luck.

With the gun I mentioned, my brass did not exhibit rim problems, and ejection was perfect otherwise. I had clear marks of brass rubbing on the inside of my port, my gun is stainless, so attacking the inside wall was easy.

Heavier springs, IMHO, are only needed to keep the slide from travelling rearward with excess force due to hotter loads. And even then there are better "fixes". Using springs to fix problems that are not spring related may appear to "fix" a problem, but will more likley mask things, and perhaps inject unwanted consequences, that may not be readily apparent.

I called Springfield. To port lower and install extended ejector is $90. not a bad price.