On another thread, I posted photos of pistols that had port cuts done after purchase. As with many things I've learned to do on these fine ol' guns, a lot of what I learned was by trial and error. For example, here's the first one I ever did. Here's how it started...

[PICTURE 404]

And here's how it ended up...

[PICTURE 404]

I first got started building 1911s through an absolutely superb on-line course offered by Dave Sample, a retired pistolsmith in Arizona who recently passed away. Dave continued to help me after the fact, and I also have benefitted immensely from the kind assistance of true top-flight pros, such as Chuck Rogers, Dave Erickson, Pete Single, Bill Zollo, and others. One thing Dave and Chuck mentioned right off was that I had left the front, lower corner of the port at way too sharp an angle. As it was explained to me, that increased the odds that the slide would eventually crack right there in the junction of the angle. In the above photos, you can see how sharp the angle is at the front, bottom right of the port.

In light of that, here are photos of the second port I ever did (also by hand). You can see that I left the lower line more rounded and also that I left a soft curve at the front bottom of the port. I did that in an overabundance of caution to not make the hard-angle mistake I'd made on the earlier port...

[PICTURE 404]

So, as you can see, the first port is way too angular, and the second is way too soft. The ideal is right in between - a straighter lower line that is parallel to the bottom of the slide, and a lower, front right transition that is neither sharply angular nor softly curved. The ideal (at least for me) is shown in the following photos, which are port cuts done by Mr. Chuck Rogers. To say that he is a master machist would be an understatekment.

Jon, any way you can tell me what the exact radius is that he is cutting in the lower section of the port?

Hi, Short. From what I've read around the net, heard from more experienced folks, etc., I don't think there's IS a "standard" radius. Here is a link to a great link about how Bob Rodgers does it:

http://forums.1911forum.com/showthread.php?t=178790

As you'll see, he doesn't disclose the exact radius of his own cut, but again, the he explains the reason by saying that there is no standard, and that it's a matter of some "artistic license." However, if you read what he says about using the tool at an angle to determine the length of the front radius and his other steps, you can probably get a ballpark idea as to what mill attachment he uses for the initial cut. One of the key things I got out of the thread was that when making the front relief cut, the tool is set at a downward angle into the port, not straight down at 90 degrees to the flat.

A little more info (that you didn't ask for - lol!): As for the horizontal wall of the port, from what I've ascertained through reading around the web and discussions with smarter folks than I is that most folks tend to lower the side wall to somewhere in the neighborhood of .430 to .450 above the bottom of the slide. Some top pros (Bob Rodgers, for example) go as low as .400, but if slide has a rollmark below the port, he just brings it down only to the point that the area above the mark is in sync with the area below it - just sorta splits the difference at about .500. On the high side, I think Gold Cups run only down to about .475.

P.S. - Oh, and interestingly (to me at least), I picked up a couple of 1991A1s to practice on, and I found that they already had the front cuts done at the factory. Not as pronouced as those in the Rodgers photos, but still there. Cool!

Jon, any way you can tell me what the exact radius is that he is cutting in the lower section of the port?

Hi, guys. Sorry I didn't notice this question before. To answer it, no, I'm sorry, but I don't know what the exact radius is. I do it by eyeball, and actually, I did it a little differently on another pistol I've been working on - more like the way Mr. Chuck Rogers (www.rogersprecision) does it, with what appear to be mirror-image radii at the front and back of the port.

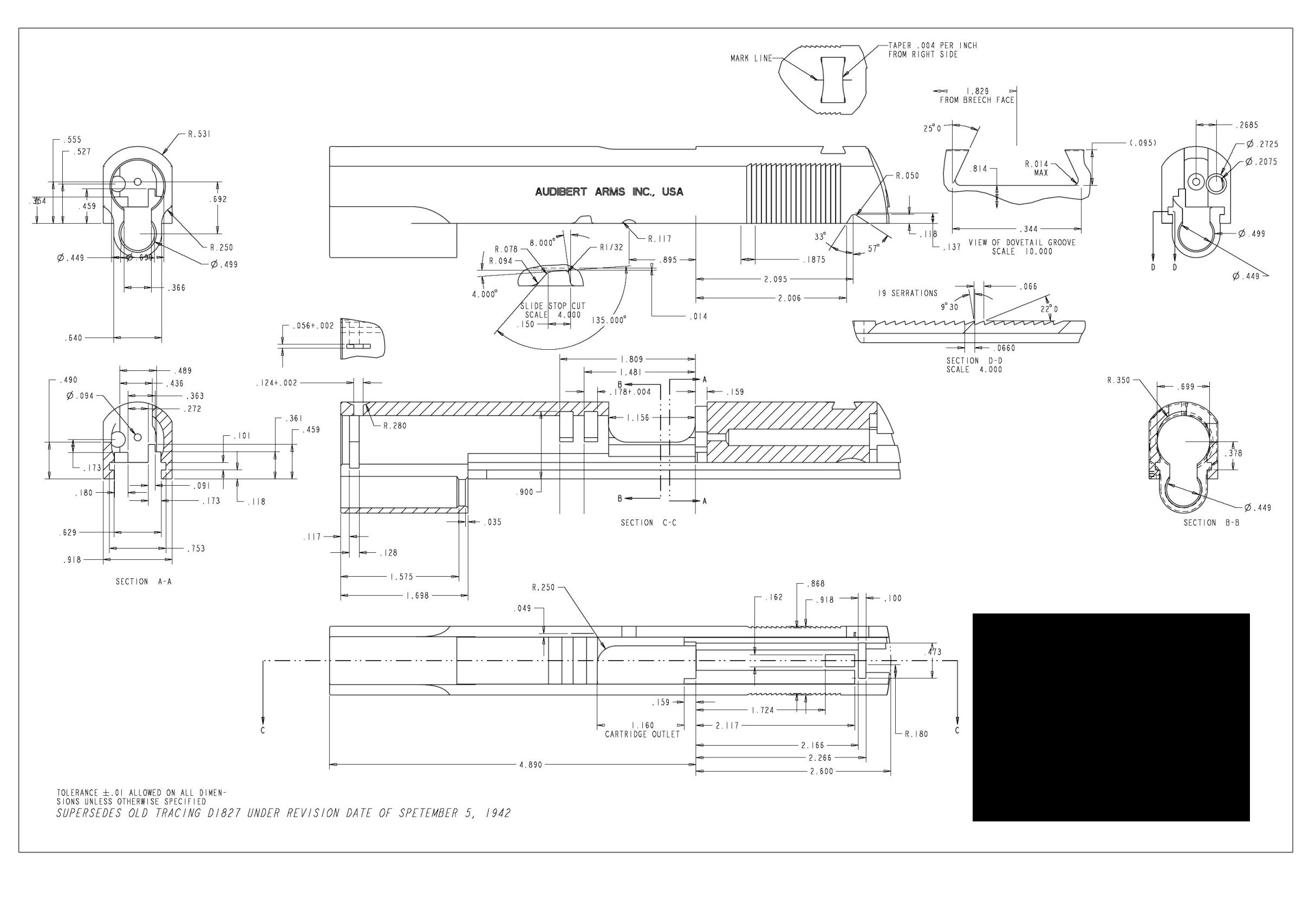

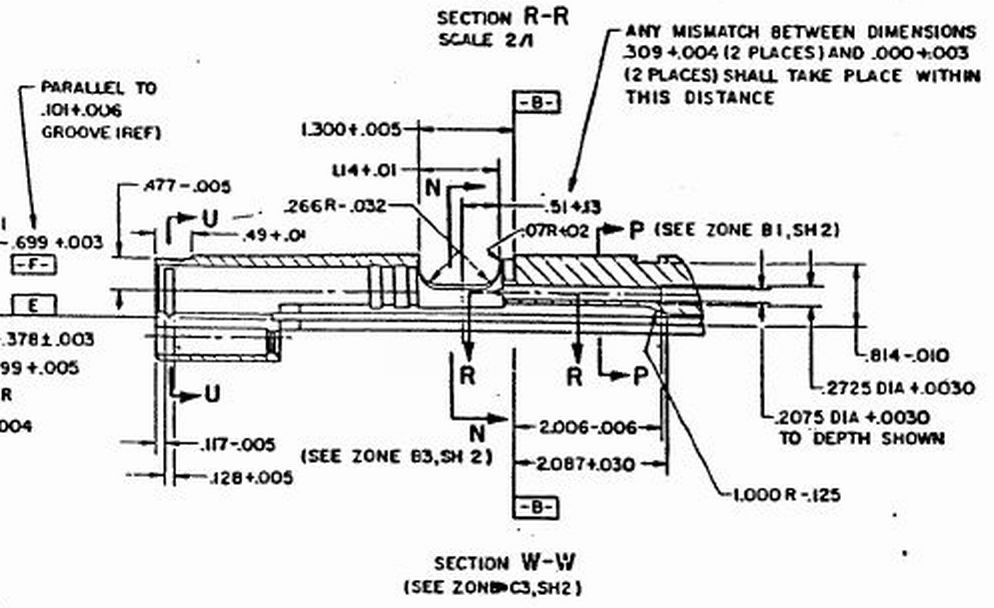

I'm posting the 1911 blue prints with radius data now in downloads...

And I have this. Quality ain't so great with this set.

and one more