Is it normal to see a small crescent shaped marked on the breech face from it contacting the portion of barrel hood right above the extractor cutout?

The crescent is silver, not to sure if it is the bluing that is worn away, or the chrome from the barrel hood.

Yes, it is the the way it works, when a round is chambered the slide/breech face hit the end of the barrel hood and push it forward into battery.

The hood is not supposed to touch the breech face since that would affect headspace.

The sides of the breech face should contact the rear of the barrel on each side and close the action.

A very small clearance (barely a few thousandths) is normally used in a well fitted barrel, along with some bevel to allow for barrel tilt down.

Oops, That's something you may have observed, but is way off in thinking and practice. Headspace is the distance from the breech face to the shoulder when the barrel is as far forward as it can be in the slide and where it will be when fired.

The closer the hood end is in contact with the breech face, it can be, to hold it there, the better. You're mentioning the breech guide blocks and barrel chamber faces and they should not contact, but may in some factory drop-in barrels. Wrong.

There is no need for a bevel on the end of the hood as the 1911 barrel does not tilt down, it tilts up at the chamber end when in battery 52' and the breech face is also cut to the 52' angle so they are square to each other, tangent, and when it links down there is clearance. In a well fitted barrel the clearance is as small as possible as to allow the barrel to link down .0005" -.001". In other words the hood end's responsibility is too control the position of the barrel relative to the slide upper lugs so engagement is aligned with as little clearance as possible.

I am even more confused now.

LogMan, so you are saying that it IS normal for the barrel hood to rub, and leave a mark or scratch around the breechface?

Absolutely!

The rear of the hood is NOT supposed to touch so that it will NOT have any effect on headspace.

While the barrel lugs and slide recess will ulitmately set headspace under firing, having the barrel hood participate by actually touching the breech face is not desirable.

Quote:

There is no need for a bevel on the end of the hood as the 1911 barrel does

not tilt down.

Funny, but the barrel tilts down pulled by the link every time the gun cycles.

Last time I looked the slide could not move up to unlock.

The barrel tilts down by the depth of the locking lug engagement.

The last thing you want is an area as small as the hood being used to apply any force to the barrel.

I think the statement that the barrel "does not tilt down" means that the barrel is tilted at an angle when it's locked, and it's more-or-less horizontal when it's unlocked; it tilts up, it doesn't tilt down.

RickB beat me to it.

1911's feed with the bore axis parallel to the rails. The breech end rises during lock-up.

Glocks are parellel while locked-up, and do drop the breech end during feeding, below parallel relative to the rails.

This has an effect on cycling if some type of weight is on the end of the Glock barrel, say a silencer. As the slide moves back it must lift the weight, slowing the slide more then it would on a 1911 type.

Did that help, or just cloud the water?

Just too funny weird. Okay brickeyee you say the hood shouldn't touch and that the sides of the breech should touch the sides of the barrel, if the hood touching the breech face would affect head space why wouldn't the other contact have the same affect?

How many barrels have you fit and have you ever even read the barrel fitting instructions by many?

When the slide is closing and chambering the breech face makes contact with the hood end and pushes the barrel forward, this arrangement aligns the barrel upper lugs with the slide lug recesses so engagement is accomplished smoothly, in other words the lugs are perfectly aligned by the hood's contact before engagement. Now when the gun is shot the barrel is pulled forward by the bullet and the slide is pushed back by the case. The minimal clearance between the hood and breech face has a positive affect, as the amount of clearance is used up when the barrel slams forward and the slide jerks back, if there was .001" of clearance between hood and breech face the barrel and slide will move in opposite directions until the .001" used up and is stopped by the barrel and slide engagement. The hood cannot affect head space, which is the distance from breech face to chamber shoulder when the barrel is as far forward in the slide as it can be, the tighter the hood is to the breech face the closer it is to that. And the better!

Quote:

The last thing you want is an area as small as the hood being used to apply

any force to the barrel.

The force at the end of the hood is a small area, but even smaller is the lower lug feet that stop the barrel and slide(by virtue of the hood contact) against the slide stop pin. It is enough however.

Quote:

Funny, but the barrel tilts down pulled by the link every time the gun

cycles.

Last time I looked the slide could not move up to unlock.

The barrel tilts down by the depth of the locking lug engagement.

This was addressed in this earlier post. And will add that the barrel at link down drops the amount of engagement plus a minimum of .010" at the .250" point of slide movement during recoil.

Quote:

The hood is not supposed to touch the breech face since that would affect

headspace.

All of my pistols, of 1918-2003 vintage (including USGI guns) have barrels that contact the breech face. I guess they must all be defective.

Quote:

The sides of the breech face should contact the rear of the barrel on each

side and close the action.

All of mine vary from slight to no contact on the left side, and no contact on the right.

I'm with Log. Hood contact is very desirable and does affect headspace.

Quote:

I'm with Log. Hood contact is very desirable and does affect headspace.

This sounds like a contradiction, to what I've stated, but isn't, the point of affecting head space is if the hood is short the static head space will be shortened, but will not affect the dynamic head space which is the measurement to cut head space to. A tight hood to breech face fit will keep these two numbers very close. Many will measure head space by measuring from end of hood to chamber shoulder as they know the hood to breech face clearance is .001" or even less and head space can be a variable of .898"+.010". Check some brass and you find quite a variable there, should be, .888"-.898", but you will find shorter is common.

Semantics. Or I was clumsy in my writing. But we agree.

Headspace in the 1911 is the distance from the bottom of the chamber to the breechface, with the barrel as far forward as possible.

When a hood is nicely fit, there will be insignificant difference with the above vs chamber depth as measured from the end of the hood.

Brickeye may have a different technique for barrel fitting. There are many ways to skin the rabbit. What works for you is what counts... to you.

Quote:

Is it normal to see a small crescent shaped marked on the breech face from

it contacting the portion of barrel hood right above the extractor cutout?

I would equate this to the marks found on a Smith & Wesson revolver's recoil plate - the right side (gun pointed away) - in which you can over time see the outline of the cartridge head caused by repeated recoil. If it's a slight shadowing on the 1911 breech face I wouldn't be concerned, if it is a distinct impression that can be felt I would be concerned.

Anyone who'd like an explanation of the relationship of hood-to-breachface contact and headspace might like to read the following staring with post number 7.

http://forums.1911forum.com/showthread.php?t=228525

It's a nice, slow explanation. Why? Because log man had to spoon feed it to me in a way I could understand.

Quote:

Many will measure head space by measuring from end of hood to chamber

shoulder as they know the hood to breech face clearance is .001" or even less

and head space can be a variable of .898"+.010".

Bad method.

Use the correct gauges, and shim them if you want.

When the action closes I want the sides of the breech face pushing on the back of the barrel, not a small area like the hood. Since brass is always shorter than the chamber, pressure from the breech face on the round and then to the front of the chamber is not going to happen.

Those nice two shoulder on the breech face are there for a reason besides simple controlled feeding.

For anything except a bullseye gun you should not need real contact with the hood on either side either. A very small clearance is just fine.

Quote:

Use the correct gauges, and shim them if you want.

When the action closes I want the sides of the breech face pushing on the back of the barrel, not a small area like the hood. Since brass is always shorter than the chamber, pressure from the breech face on the round and then to the front of the chamber is not going to happen.

Those nice two shoulder on the breech face are there for a reason besides simple controlled feeding.

For anything except a bullseye gun you should not need real contact with the hood on either side either. A very small clearance is just fine.

The funny thing about this discussion is once the round is fired there isn't any pressure on either the hood or the guide blocks against the barrel face (where can one get barrels with that much meat on the barrel face anyway, besides being wrong) as the barrel and slide are pulling in the opposite directions.

Quote:

Since brass is always shorter than the chamber, pressure from the breech

face on the round and then to the front of the chamber is not going to

happen.

Okay, maybe this is where you totally miss the point about my reference to the barrel and slide going in opposite directions. As I would agree the brass isn't going to do it, unless the head space is really short, and specs. call for the head space to be greater than brass specs.

What does cause the barrel and slide to go in opposite directions is the explosion of gases at ignition, the pressure builds forcing the bullet out of the case. The case has no where to go as it is now against the breech face exerting the full force of the explosion against it. While the bullet is being swagged into the rifling with the same equal force. The slide/ breech face/case and bullet are literally blown in opposite directions and the bullet is trying it's best to take the barrel with it as it is expanded against the side walls of the bore, stopped only by the radial lug engagement. This battle is what keeps the action closed until the bullet exits, but the slide and barrel does move to the rear about .100" during the time the bullet is still in the barrel, due to the fact the bullet is losing the tug of war and is being expelled, while the breech face is holding the case in check. Once the bullet is expelled and no longer holding on to the barrel by friction the case takes over with it's momentum and we have full recoil.

It is this slamming affect of the barrel going forward and the slide/breech face being slammed back and their separation only being stopped by the radial lug engagement that makes the hood length so important. Think of two identical trucks face to face and whose bumpers are touching and both are in Drive, when the drivers hit the gas, no damage to the bumpers, just spinning tires. Now separate the two by 12" and hit the gas. Bent bumpers. The biggest cause of radial set back is a short hood. A closely fit hood, which bears none of the force of ignition, but positions the radial lugs as close as possible so as to reduce the slamming affect. A good thing.

Because the recoil spring is pushing the slide as far forward as possible, stopped by the hood and if over cut then the breech guide blocks and chamber face or the forward face slide lug recesses bearing on the rearward barrel lug walls. So the clearance between the hood end and breech face is always less in appearance then it really is. To determine how much slam there is when your gun is fired, insert progressively thicker shims between the breech face and hood end when the slide is back ¼" or so and close to battery, when it won't close anymore you'll know how much your barrel and slide's running room is before the slamming of the barrel and slide radial lugs occur.

I have a 9mm barrel hood that is .005" from the breech. Is this excessive?

What is the ideal distance from the breech face?

rich - the way I understand it, that .005" is neither excessive nor not excessive. Instead, it is a progressive thing. In a nutshell, the reason the back of the hood should be left in contact with the breechface does not have to do with setting headspace. Instead, it has to do with how long headspace stays set. Leaving the back of the hood in contact can help keep the upper lugs from setting back as quickly over time and degrading headspace because the gaps between the upper lugs and recesses are minimized. Now, having said that (and also admitting that I've never fit up a 9mm and so can only go on .45 ACP), the Kart EZ instructions say a gap of .003 is fine. While that's not "in contact" or "in soft contact," if .003 presents no real problems then I can't see that just another .002 would make any appreciable practical difference.

He did raise an interesting point about the breech blocks. In the earlier thread I mentioned where log finally turned on a lightbulb I could see, I had couched the original question as, "What are these blocks for?" Am I correct in still understanding that that they are only there to help guide the cartridge head up the breech face and under the extractor, and that they are not supposed to contact the back sides of the chamber (e.g. provide additional support as the barrel goes back to battery)?

Quote:

He did raise an interesting point about the breech blocks. In the earlier

thread I mentioned where log finally turned on a lightbulb I could see, I had

couched the original question as, "What are these blocks for?" Am I correct in

still understanding that that they are only there to help guide the cartridge

head up the breech face and under the extractor, and that they are not

supposed to contact the back sides of the chamber (e.g. provide additional

support as the barrel goes back to battery)?

A big yes, the left side as I mentioned before is how the extractor has the ability to extract by pinning the case against it. So it is very important in it's function and of course the right side houses the extractor. Also how the radius is cut so the case can't go too high up the breech face when it's being extracted and get pushed up by the cartridges in the mag and get missed by the ejector. Sorta like.

The idea that the barrel needs additional support is an unfinished thought as the hood only correctly positions the barrel for radial lug engagement, and once the barrel rides up the slide stop pin on the lower lug or rides the link into battery, the radial lugs give the barrel all the support it needs.

Quote:

I think he is wrong, and he has presented no real factual evidence to the

contrary besides his own words.

I am in the same boat to some extent, but have done plenty of Bullseye work over the past 25+ years.

I am he who you believe to be wrong. How ever I have presented factual evidence in regards to the operation of the 1911 upon firing and the consequences of a short hood. These are not ideas that I conjured up or developed through fantasy, but are the culmination of developing an understanding of how the 1911 best functions.

Your arguments haven't any merit as you haven't explained how a short hood is a benefit, as your reasons to date are not true or relative to the function of the 1911.

Jerry Keefer is the consummate bulleye gun builder, and I will suggest to you that you have nothing in common with him or his knowledge of the 1911.

25 years for you and 5 years for me since I first purchased and fired a 1911, catch up. I don't voice opinions, but share an understanding about which I have focused. You surprise me to be in such disagreement, not with me, but the likes of Chuck Rogers, George Smith, Fred Kart, Wil Schuemann, Irv Stone, Ed Brown, DSK, Big Jon, LogicGS, and many, many others, I love to learn teach me something as these people have.

Quote:

rich - the way I understand it, that .005" is neither excessive nor not

excessive. Instead, it is a progressive thing. In a nutshell, the reason the

back of the hood should be left in contact with the breechface does not have

to do with setting headspace. Instead, it has to do with how long headspace

stays set. Leaving the back of the hood in contact can help keep the upper

lugs from setting back as quickly over time and degrading headspace because

the gaps between the upper lugs and recesses are minimized. Now, having said

that (and also admitting that I've never fit up a 9mm and so can only go on

.45 ACP), the Kart EZ instructions say a gap of .003 is fine. While that's not

"in contact" or "in soft contact," if .003 presents no real problems then I

can't see that just another .002 would make any appreciable practical

difference.

Big John, man did I need to read this! I did a hard fit on one of my project 1911's, and somehow, I wound up with approximately .001" of clearance between the hood and breech face. Can you believe I have actually lost sleep over this? I have.

The gun is shooting 1.25" at 25 yards (on a really good "trigger finger day") so there isn't much room for improvement.

Quote:

Big John, man did I need to read this!!! I did a hard fit on one of my

project 1911's, and somehow, I wound up with approximately .001" of clearance

between the hood and breech face. Can you believe I have actually lost sleep

over this? I have.

Lol! I'm with you, schmeck' - My brow was furrowed for the better part of a year, or maybe even more, wondering whether or not the back of the hood should be in contact with the breech face or not. Some said yes, and some said no, and I could never seem to find anyone who'd explain WHY that was his opinion. Actually, I did find that the Kart booklet, and it had a good explanation, but then I'd read "hard contact!" by some guru, sho' nuff pros who post here and be back to square one.

Your thanks is most appreciated, but misdirected - it needs to go to the log man. If it weren't for him I'd still be in deep confusion about that. I'm glad my post helped, but if it weren't for his unique ability to patiently drive water into a rock I couldn't have posted it.

Next questions ...

Assumptions:

* The gun is in battery

* Frame and slide are in spec

* All parts are in spec, including the thickness of the lower-lug feet

* The front face of the lower lugs is in contact with the slide stop

* The back of the hood does not touch the breechface

* Factory barrel

With those assumptions, ...

Question 1: Are the breech blocks in contact with the sides of the back of the chamber?

Question 2: If so, is forward pressure from the breech blocks against the sides of the chamber what's keeping the barrel forward and in battery?

quote:

Jerry Keefer is the consummate bulleye gun builder.

I have been watching this exchange, but had decided to remain silent. There isn't much I could have added to your excellent explaination. I also felt it impossible to dissuade those with antiquated, beliefs/myths, to the simple, basic facts that most all notable smiths have known for decades.

Camp Perry is in full swing as this is written. We can safely bet the farm, that nearly all 1911s on that line of any merit, are making full, hard contact with the breechface, with known static headspace, and clearanced at the chamber face sides.

Quote:

Question 1: Are the breech blocks in contact with the sides of the back of

the chamber?

Question 2: If so, is forward pressure from the breech blocks against the

sides of the chamber what's keeping the barrel forward and in battery?

Oops, I just buzzed right past, thinking you where making a statement.

Kinda funny trick question really.

1. Maybe, depends, but most likely, if not, then the forward lug recess walls of the slide would be pressing against the rear lug faces of the barrel.

2. If maybe of 1. is yes, then 2. would be yes.

Does it really matter?

Probably got your attention there, at least I hope. Let me clarify that a bit.

In battery, round chambered, you want the front of the barrel lug(s) in contact with the front of the lug cutouts (rear of the lugs) in the slide. Or with minimal clearance (0.001?) to prevent battering.

Question 1:

Does it matter if

a) the breechface blocks provides/barrel chamber side the push into lockup OR

b)the breechface/barrel hood?

As long as the headspace, breach face to chamber shoulder, is within sped.

Question 2:

Once in battery, wouldn't the ideal be to have no clearance in the lug

engagement?

Question 3:

Wouldn't it provide even better lockup and headspace control to have both the

hood and chamber sides in contact with the breech face and breech blocks,

respectfully?

I'm just trying to understand why one is preferred over the other, they would both accomplish the same thing it seems to me? Isn't the goal is have the consistent headspace when the barrel/slide is locked and minimal lug clearance?

Quote:

I'm just trying to understand why one is preferred over the other, they

would both accomplish the same thing it seems to me? Isn't the goal is have

the consistent headspace when the barrel/slide is locked and minimal lug

clearance?

Here's something you have to realize, most 1911s and their parts are within a set of specs. and the barrels are made to fit. Since the 1911 was designed to have the barrel closed by contacting the hood end, barrels are made with a little extra hood length so it can be fit. Rarely, if ever do the breech guide blocks contact the chamber face and hold the barrel far enough forward as it wasn't intended too. The funny catch is there is normally .005" or a little more between the blocks and the chamber face, so when a drop-in barrel has a hood that is designed for not fitting it must be short and guess what the blocks take over. Is that okay? No! It isn't because the radial lug engagement is sloppy in battery and gets battered at every shot. No argument Colt and others have shipped thousands of guns set up this way, but it's not right. It's expedient. Can you shoot thousands of rounds through it? Sure. Will it be as accurate as a correctly fit barrel? No.

Fitting the hood fills the bill, fitting the blocks and chamber faces does not, that would really be awkward. To get 99% or more of the barrels made to give a good lock up in respect to the radial lugs they would have to be welded up, as they don't have enough material to hold the barrel forward enough by registering on the blocks. That's the way it is!

That should really answer all three of your questions. But just in case.

1. The hood is the correct choice as it can be fitted to hold the barrel as far forward in the slide as possible with minimal fitting.

2. Yes, it would and a bolt action or a true locked breech gas operated action is the answer for that. The 1911 semi-auto requires that the barrel chamber end be capable of dropping down to extract and re chamber. It can be done with less than .001". And .002" is just fine also.

3. No. Setting one, the hood is as good as it gets, if the blocks could be fit to exactly the same contact it would not be an improvement it would just be the same!

And lastly it isn't a choice it's a design. I like it!

With regard to your first two questions, here's a key point that we seem to be missing: whether a gun has rear-hood to breech face contact and whether it locks up on the slide stop are not issues of "good" or "bad." Instead, they're either "necessary" or "unnecessary." Which it is depends on what performance you expect out of YOUR gun. Contact is a necessary step only if you want headspace to last as long as possible and for the radial lugs to engage as smoothly as possible. Lockup on the slide stop is only a necessary step if you want the most in accuracy from your gun. In either case it depends on whose gun it is and his performance expectations.

As for the 1911 not being designed for Camp Perry, that's like saying that factory hunting rifles aren't designed for long-range competition, or passenger cars aren't designed for the race track, or even I'm not designed to pay income taxes. In each case, the stock example can be modified to perform the assigned task extremely well if the incentive is there.

'I think the statement that the barrel "does not tilt down" means that the barrel is tilted at an angle when it's locked, and it's more-or-less horizontal when it's unlocked; it tilts up, it doesn't tilt down.'

Tilted at an angle to the reciever? No. It's level when locked and down at the rear whenthe slide is open. How can anybody say such a thing when it's right in front of your face? Look at the animations - the bushing has to allow the barrel to tilt down so it can unlock. At this point the chamber is visibly lower than the muzzle. As the barrel tilts back up to lock, it comes parallel to the slide rails. I mean it's obvious! How can it not be?

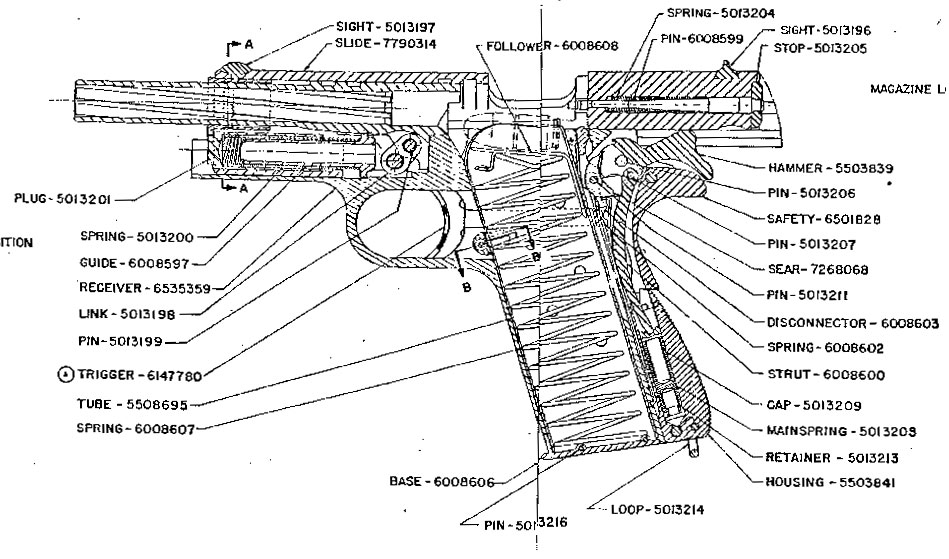

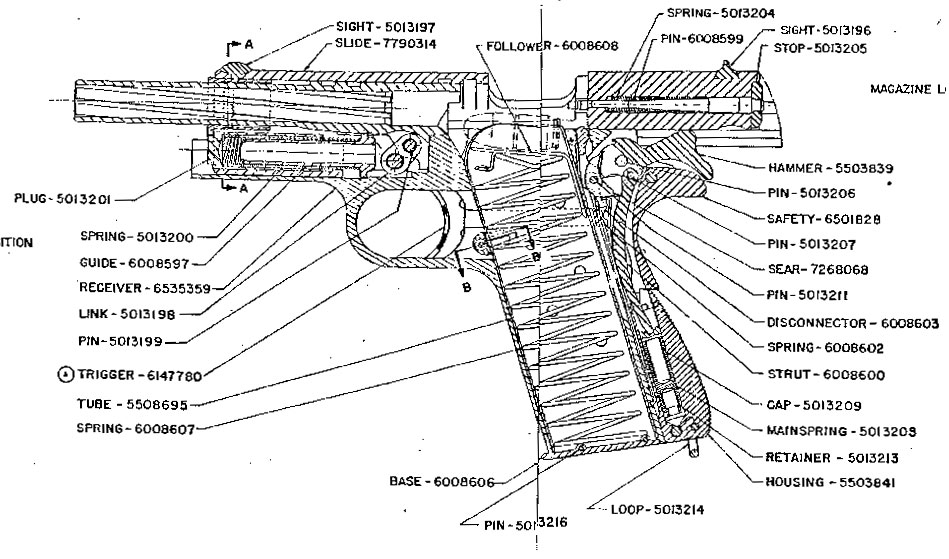

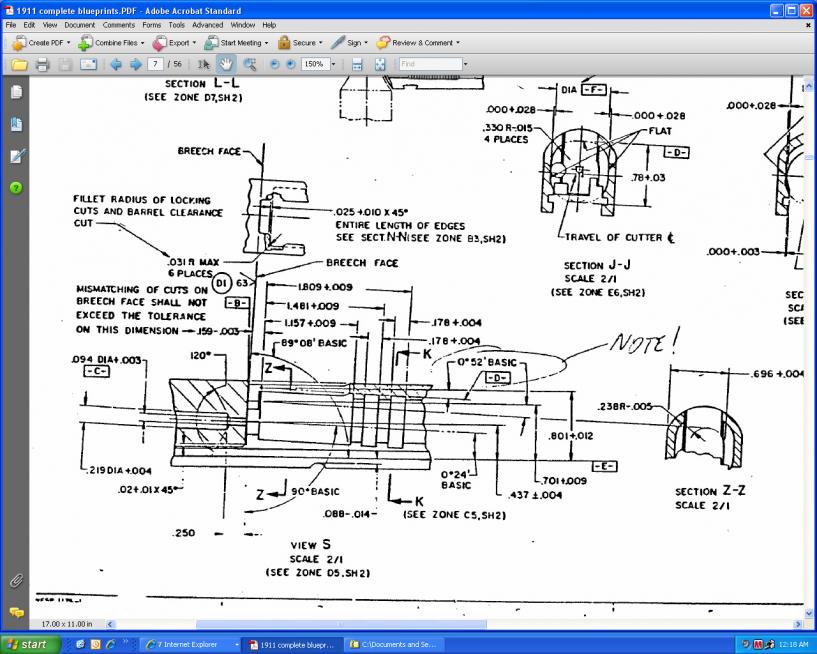

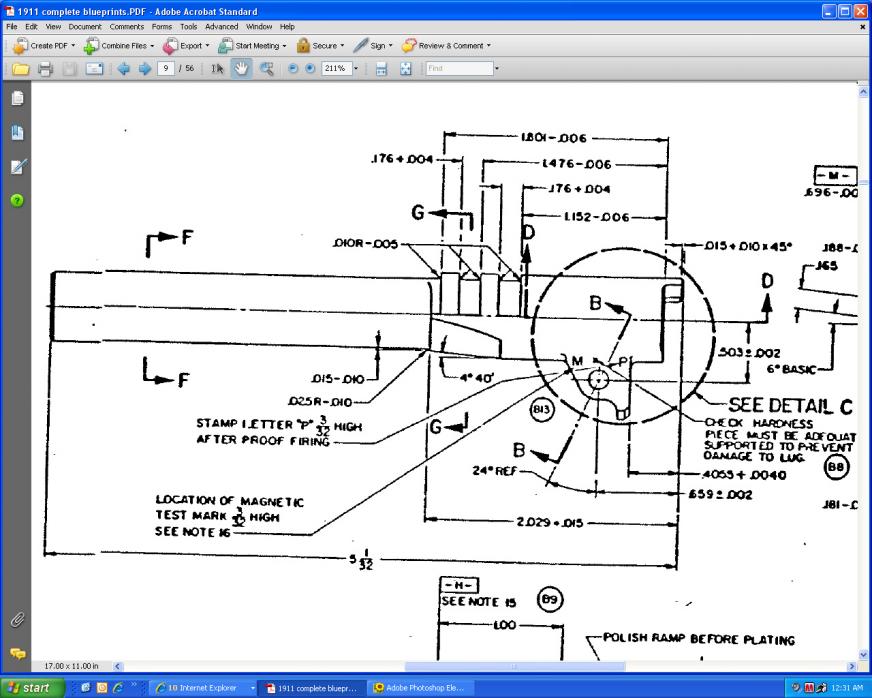

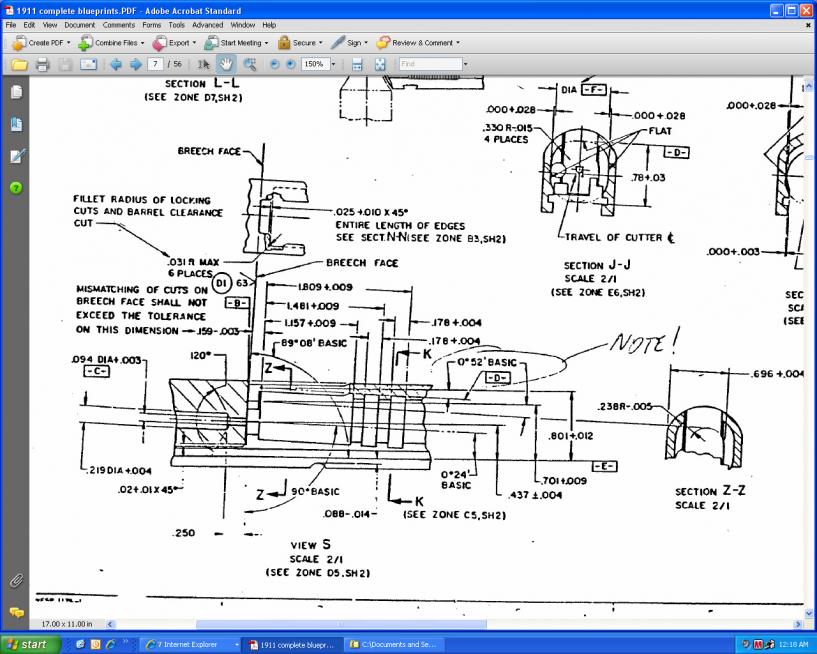

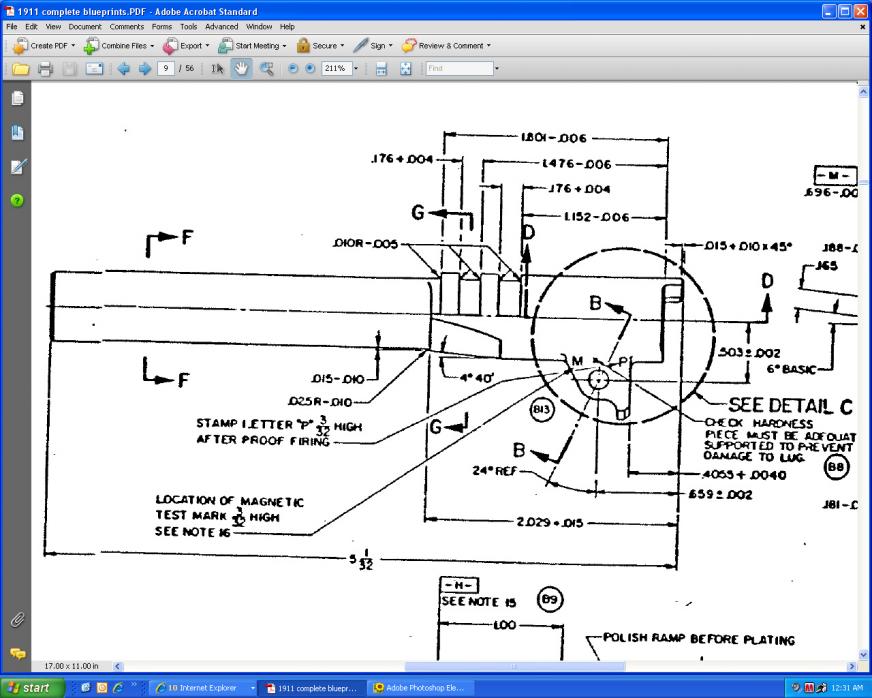

I can settle this right now, for I have in my possession blueprints.

Observe:

Unlocked

Notice how the inside bore of the slide and the barrel are parallel in that pic? That means they're both horizontal when the works are unlocked.

Locked

See that little angular dimensiion shown on the centerline of the bore? That's telling you that the barrel is tipped chamber up in relation to the slide when everything is in lockup (Zero Degrees, fifty two minutes up, or just shy of one degree, if you can read it).

That's it, and that's all.

In a 1911, the barrel tilts up at an angle to lock, while it unlocks and tilts back down to horizontal to feed.

You are all saying the same thing. With the slide on a level horizontal plane, the barrel is tilted about a degree when it's in battery and parallel to the slide when it's linked down. What's causing the confusion is that you're defining "tilted" in a different way. If everyone starts with the assumption that the slide is level horizontally the issue will clear up I think.

Quote:

I think the statement that the barrel "does not tilt down" means that the

barrel is tilted at an angle when it's locked, and it's more-or-less

horizontal when it's unlocked; it tilts up, it doesn't tilt down.

Tilted at an angle to the reciever? No. It's level when locked and down at the rear whenthe slide is open. How can anybody say such a thing when it's right in front of your face? Look at the animations - the bushing has to allow the barrel to tilt down so it can unlock. At this point the chamber is visibly lower than the muzzle. As the barrel tilts back up to lock, it comes parallel to the slide rails. I mean it's obvious! How can it not be? BECAUSE IT ISN'T! OUCH!

On this forum we're talking about 1911 pistols not Glocks which are parallel to the slide and frame rails when in battery and the chamber end does tilt down from horizontal during recoil and chambering. However the barrel in a 1911 is parallel to the slide and frame rails when unlocked and the chamber end is up, 52' or nearly 1º when in battery, ahem and is why as you pointed out the bushing is clearanced front lower and rear upper. The breech face is also on a 52' angle so it is square with the barrel when in battery.

I mentioned awhile back that I'd been trying to get the answer to the hood- rear to breach face question for years. Well, while researching something else just now I ran across one of those old threads. Thought y'all might like for several reasons - brickeye explains his position in post 16. Also, it includes information from some folks we haven't seen in awhile, such as our departed friend Mr. Bob Brown and also Mr. Bob Marvel. In post 11, Mr. Marvel explains why he advocates leaving a .001 gap* between the hood rear and breech face. Seems to me that if you fit the hood with soft contact you'll be at .001 after you've shot the gun just a little bit.

http://forums.1911forum.com/showthread.php?t=183182

* Marvel does not advocate leaving a gap (See Keefer, Post 71).

Interesting. Everything that Marvel said is correct as I understand it. What he didn't explain is why it's important in regards to what happens when the gun is shot and the slide tries to recoil and is held by the bullet dragging the barrel forward.

I'm confused... again!

In this thread brickeye says:

"The hood is not supposed to touch the breech face since that would affect headspace.

The sides of the breech face should contact the rear of the barrel on each side and close the action.

A very small clearance (barely a few thousandths) is normally used in a well fitted barrel, along with some bevel to allow for barrel tilt down."

and:

"The rear of the hood is NOT supposed to touch so that it will NOT have any

effect on headspace.

While the barrel lugs and slide recess will ulitmately set headspace under

firing, having the barrel hood participate by actually touching the breech

face is not desirable."

And:

"The hood is not supposed to touch the breech face since that would affect headspace."

Yet, in this thread:

http://forums.1911forum.com/showthread.php?t=183182

He states:

"Both of my Bullseye guns have only enough clearance on the sides of the hood

for operation, and less than 0.001 from the rear of the hood."

Uhhhhhh...?

I'm not intentionally attempting to embarrass anyone that is here to help.

But this is a 'technical forum' that should deal in facts.

Maybe my reading comprehension has been compromised by the Lead Azide by-

products from small arms primers.

Quote:

Yes, I'm with you. He mentioned several times the matter of smoothly and

consistently getting the upper lugs into the slide and repeatability but not

minimizing lug battering (one of the big eye-openers you laid on me back on

that thread earlier this year).

He did, though, mention something else that I don't think (?) has been tied

in here with repeatability and headspace longevity: whether leaving a slight

gap* that is neither hard contact nor greater than .001 (Marvel #20) might

provide virtually the same benefits on headspace longevity and repeatability,

plus "operating clearance" (brickeye #16) which I take to mean the elimination

of tolereance stack (brickeye #8) and/or firing crud (Bob Brown #10). This

will be getting into somewhat uncharted territory for me.

It was fun finding that old thread. I understand so much more than I did then

(but I still have so far to go.)

As mentioned, a great thread, if one can keep the terminology for all the

parts and pieces straight to understand what's being imparted.

The most surprising bit of info to me is the barrel angle in lockup, I always

assumed it was parallel to the slide axis at lockup. So it shoots down!

I have a Colt that locks up on the breach blocks and has 0.001-0.002 lug

play. Another, none Colt, locks up on the hood and has ~0.0045 lug play.

Clarification please, the diagram showing lockup, what is the "headspace"

range shown, I can't make out the numbers clearly, perhaps 0.904 to 0.0923?

Quote:

The most surprising bit of info to me is the barrel angle in lockup, I always

assumed it was parallel to the slide axis at lockup. So it shoots down!

I have a Colt that locks up on the breach blocks and has 0.001-0.002 lug

play. Another, none Colt, locks up on the hood and has ~0.0045 lug play.

Clarification please, the diagram showing lockup, what is the "headspace"

range shown, I can't make out the numbers clearly, perhaps 0.904 to 0.0923???

Thanks for all the info.

The print says:

Breeching Space

It does get confusing, as terms are not always understood the way the author

means them. Oh really! For instance, this was clarified by Bob Marvel in the

linked post, but wonder if all caught it. And then brickeeye says something

similar, is he saying the same thing. When it's announced that I have .001" of

clearance between the hood and breech face, what exactly does that mean? I

know what it means to me, but suspect others see it differently.

What I mean when saying that I can slip .001" in between the hood and breech

face, means when the slide is back, it will just close to battery on it, any

more and it won't close. That means when the gun is in battery there isn't any

clearance between the hood end and breech face, as the recoil spring is

holding the slide forward and that .001" is now in between the radial lug

faces.

While I'm afraid that some who may believe the slide should rest against the

guide blocks and chamber face and will say that they have .001" between breech

face and hood end and mean that's the way it is when in battery, and the

amount of clearance between the radial lugs is... a lot.

There are many thousandths of difference between these two examples.

Jon...

Please read Bob's post again. He does not advocate .001 clearance... he

states it should not "exceed " .001. I would be unhappy with .001 clearance.

It's not fatal as Bob states, but that's not our goal, and a failing as a

machinist.

There's no real mystery to it. It's the same principle of ballistics adhered

to by the rifle gurus... ballistics are ballistics regardless the barrel

lenght.

May I trouble you guys with another question to try to get this wrapped

together in my brain?

Assuming we're talking about a typical factory gun, if the rear of the hood

is not in contact with the breech face when the barrel is in battery, what's

holding the barrel forward? Is it the breech blocks pushing against the barrel

faces, or the the front faces of the of the upper lugs pushing against the

rear faces of the slide recesses?

Am I correct in my belief that it has the former? Or is there enough

tolerance range for it to be either one in a particular pistol?

The breech blocks /chamber faces are the next in line in most, as the slide

lug recesses are .020" over the barrel lugs, but it could happen.

Great. That's what I thought, and that confirms that I’m on the right

track.

I understand what you wrote in post #70, and I said earlier, it’s starting

to come together for me in chunks now. Based on what I believe to be a correct

understanding, here's how I'd answer some of the questions that have been

posted about this here and in other threads. Let me know if I missed the boat

anywhere!

quote:

No. The only way to tell is to shim between the hood and breech face to find

out exactly how far the radial lug faces are apart. The following graphic

shows how the hood may still be overcut even though its rear is in contact

with the breechface when the slide is closed:

quote:

Within reason (taking other factors such as case support out of the

question), the radial lug distance (thickness of the last successful shim) is

neither good nor bad. Rather, it is a progressive thing in that the negative

effects on cycling smoothness, repeatability and headspace longevity increase

the thicker the shim is. It only becomes “bad” if the gun will no longer

performs up to the accuracy and reliability (and longevity of accuracy and

reliability) requirements the owner of that particular gun expects from his

pistol.

The key to understanding this, I think, is to understand from the get-go that

rear-hood contact with the breech face is not a goal unto itself. Rather, it

is one of multiple, interdependent steps toward some (but not all) goals in

building some (but not all) pistols. It only matters IF you are building

toward the goals of optimizing the pistol's cycling smoothness, repeatability

and headspace longevity.

I still have a tenious grip on the idea that a bit of space isn't necessarily

a bad thing. Since its unlikely that we'll be in the trenches of WW1 again, I

don't guess it much matters.

Maybe I missed it, but is/was there a max allowable gap where the QC

Inspectors would reject the pistol before it was deemed ready for issue?

Let me try to re-phrase my question a bit better.

Wartime Colt patent sidearms were made by various folks and were subject to

QC inspection. The inspectors final 'stamp of approval' was displayed on the

product. and was required before the product was deemed Ready For Issue. No

break in period. It had to work.

So, just asking, was the barrel hood-breech face area subject to inspection?

...and if so, what was the max allowable distance?

Kinda sorta like go/no go tolerances.

I looked through the MEU SOC Pistol.pdf and

didn't see any ranges given for the hood to breech face distance in the

maintenance instructions. Maintenance steps that seem to require the greatest

degree of skill, including other matters relating to the chamber, are

addressed in the "Fourth Echelon" maintenance steps (Fifth Eschelon apparently

being send the pistol in for a rebuild), and those don't address hood length

or the gap.

But, wouldn't that make sense? I assume (?) that since these are war guns

they're designed to lock up with the barrel faces pushing on the breech

blocks, and if that's true then the size of the gap is really irrelevant up to

a huge gap size that would compromise case support.

"assume war guns case support"...

Why is it more logical for the guide blocks to make contact, except for the

fact that they are second inline if the hood doesn't. Something to think

about, the bullet and cartridge do not pass by the hood end when chambering,

the cartridge/bullet and case mouth is introduced in front of it, however the

barrel face is the sides of the barrel ramp and can catch the bullet or case

mouth. We have seen barrel faces that where peened and could raise an edge on

the barrel face/chamber entry corner, so if we're "assuming" I'd assume that

the hood would always be preferred. Just from a mechanical standpoint, war

guns or not. Don't know for a fact, but theory.

Case support is not proportional to hood or barrel face position, in relation

to the slide. But rather the amount of case exposure when the barrel is as far

forward in the slide as it can be when fired controlled by the radial lugs.

This will not change by changing the hood to breech tolerances, it will only

change through wear or through moving the barrel ramp forward.

Quote:

No, I'm not talking about what's preferable. I'm making a practical guess that

just as true drop-in (zero modification required) barrels are designed to work

in the most guns possible, old war guns had to be assembled (rather than

built) from bins of parts, and also have parts swapped around in the field, so

their parts tolerances are probably narrower toward the middle range.

Quote:

Same thing - was not trying to suggest any proportionality but was just trying

to simply this point: if the back of the hood isn't in contact with the breech

face when the barrel is all the way forward, what's holding the barrel there

are the breech blocks pushing on the barrel faces. That being the case, you

could cut the hood forward to the point the case fails without affecting head

space.

Log and Salty - here's what I'm getting at to try to simplify (which means

that up front I know that I'm making some gross overgeneralizations and

leaving out disclaimers such as "other parts are involved" and "most but not

all" etc.):

1. The upper barrel lugs on all 1911s fit up into grooves in the slide.

2. When the gun is fired, the barrel goes forward and the slide goes

backward.

3. Barrels designed to drop in with no modification are meant to "function"

(put bullets out) in the greatest number of guns. To do that, they have to be

sized toward a somewhat narrow middle range in critical areas.

4. Because true drop-in barrels are designed as per number 3, when you stick

them up into the slide there probably won't be contact between the back of the

hood and the breech face.

5. If that's the case, what's holding it forward is the breech blocks pushing

on the barrel face.

6. If that's the case, it's likely (unless you just get lucky) that no radial

barrel's lug's front face is in contact with the rear face of a slide lug.

7. The only way to know for sure that at least one of the upper lug faces is

in contact with its slide recess is to push the barrel as far forward as it

can go. A great way to check is to take shims, unlock the gun, stick one

between the breech face and hood, and try to lock the gun back up. Once you

get a shim large enough that the barrel won't go back into battery with it in

there, then you know how far the lugs are from contact with the slide

recesses.

And as log said, the breech blocks are "second in line" to hold the barrel

all the way forward if the hood isn't long enough to do it. That's why super

accurate bullseye guns are built with the barrel hood cut to push the radial

barrel lugs forward to contact with the slide recesses.

P.S. - So we don't get off into headspace, number 5 assumes an empty chamber.

I wasn't disagreeing with you at all, just trying to get my arms wraped

around a bit of understanding.

See your last post, item number 7.

That's what I was asking when I refered to a Gov't QC Inspectors' oversight of

the mfg of small arms intended for military purchase.

Was a shim, feeler gauge, etc., used to determine how much space was, or

wasn't acceptable prior to acceptance and issue?

Dang near everything else has min/max tolerances, I was just asking what was

too much.

A little space is good, a lot of space is too much, and none is just right.

With that in mind, it does seem that it'd be measured and judged against some

sort of yardstick.

1. Okay

The breech guide blocks are going to be hard put to ever hold the barrel "all

the way" forward as you state, but will pick up after .005"-.008" of over

cutting the hood and will hold it in that position relative to the slide.

I think what got salty and me salty, was;

Quote:

Doesn't make sense to me that it was a design feature, but I don't think any

of us really knows. And isn't relative to today's guns and the accuracy that

we wish for. I'm not sure but memory serves me that the requirement was an 8

inch group at 50 yds. and an over 8# trigger pull. That's not the goal today.

Yea, looks like we're all on the same page (and no, Salty, I know you're

just gettin' deeper in this, and I didn't see that you disagreed with

anything).

As for salty's question about a gauge for the old guns, I haven't looked to

see whether or not the "allowable gap" is stated in the prints, but if it

isn't I can think of a couple of reasons why. One is that that gap is a

dependent figure - the size of the gap doesn't affect operation in and of

itself, and it can calculated from the stated specs for other parts that do.

As for a yardstick such as a guage, I have no idea if the blueprints include a

gauge for that or not. Seems like there wouldn't be much point to one since

the gun would have to pass the go/no go headspace gauges and if it does that

on a gun with any gap at all the size of the gap wouldn't make any difference.

Interesting stuff.

Quote:

Yep. That's gotta be it. Here it is re-stated after a little more thought:

There would be no reason for the early armorers to need a gauge to

specifically measure the gap (between the back of the hood and the breech

face) becase there is no reason to state a tolerance range for that in the

first place.

1. You already have stated specs for the slide, so you know where the breech

face is supposed to be.

2. You already have the stated specs for the barrel, so you know how long the

hood extension is supposed to be.

If 1 and 2 are satisfied, then the issue is headspace, not the size of the

gap since it does not determine headspace. You already have stated specs for

headspace so you know what that's supposed to be, and you check that with

go/no gauges - and those ARE set out in the blueprints.

Howzat?

Pretty good, I'm not an armor nor know an old one, but know that barrel

face battering was a problem to look for, J.K. does address this and as far as

military armorers go the good ones knew when to try a different barrel. Parts

where only interchangeable to a point and they knew it. Should be the

armorer's creed to know when and when not.

Yep. And it seems that you've just come up with a reason why the following

statement is not limited in application to only folks with fancy, modern

pistols with slick trigger jobs:

An educated 1911 owner is much less likely to drop the slide on an empty

chamber when it's his own gun.

Dumb me, I still don't get it.

If barrel hood/breech contact isn't important, then we have wasted about 4

pages and 90 posts.

It was interesting to try to follow, and I will read and re-read it a few

times.

If I can offer a Cliff's Notes version of my understsanding it would go like

this: Drum roll with rim shot

Regarding QC measurement, maybe its kinda like... if A equals B, and B equals

C, then there is no need to measure A to C?

Within reason, lack of contact isn't importand as to reliability... it may

even enhance it (I added that last part hoping for yea/nay.)

It is important regarding posssible accuracy potential and longevity.

Is that about right?

Simply put: Minimal hood to breechface clearance is preferred?

Quote:

What is the ideal distance from the breech face?

While some might consider 0.005" too large for a competition gun, it may be

too tight for a combat pistol:

Aiming at less than 0.001" may give you the longest lug life due to the

shortest "slamming distance", but any lint or dirt that gets in between the

hood and breech face, or in between the locking lugs will tend to prevent the

gun from going into battery and jam the gun.

As such, it is a balance between reliability when dirty and the number of

rounds you can fire before requiring a re-build. In battle, reliability is

more important than part life - you can't carry enough ammo to break your

pistol, but you can shoot it enough in a dirty environment to gum it up to the

point of jamming, if the parts fit too closely.

Just like the truck analogy, think of a one pound hammer driving a nail into

a block of wood. If the hammer is almost resting on the nail, you cannot get

enough of a swing to generate an effective blow. If the gap is 6 to 12 inches

you can whack it.

The slide is a little lighter than that one pound hammer and while it is

accelerated by thousands of pounds rather than your hand, we are arguing the

difference between 1 and 10 thousands of an inch - not much of a running

start.

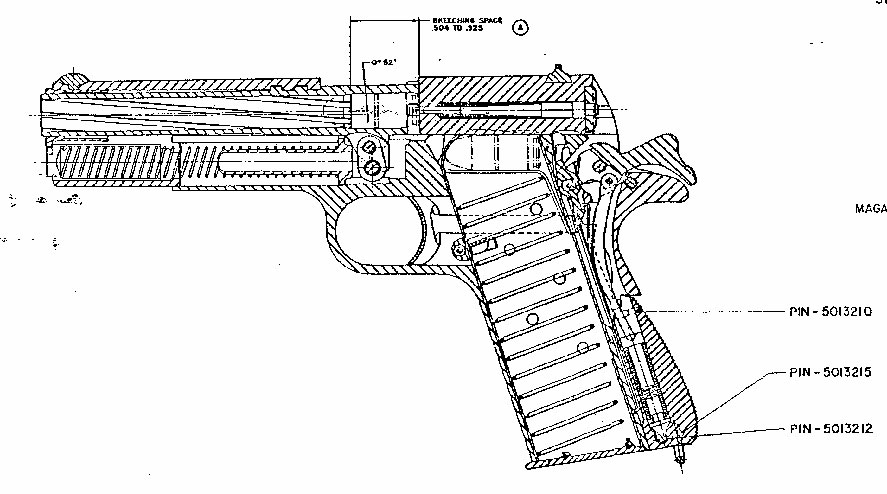

On edit I have calculated the side velocity that would be achieved as a

function of hood to lug clearance, based on the stated assumptions:

Slide velocity achieved as a function of hood to lug clearance

Distance d ....................... Slide Velocity

From: Slide Velocity = SQRT(2.a.d) and F = m.a

This calculation assumes a worst case in that peak pressure acts throughout

the distance the slide moves while taking up lug clearance.

Note that peak pressure occurs when the bullet engages the rifling, but that

all headspace and some lug clearance would have been taken up at lower

pressures before peak pressure is reached. As such, the actual velocities

would be somewhat lower than the calculated values.

Peak pressure .......... 18000 ....... PSI

Bore Area .............. 0.159 ....... SQ inch

Force .................. 2863 ........ lb ........ 12765 ... N

Slide weight ........... 0.78 ........ lb ........ 0.3545 ... kg

Slide Acceleration ..... 3670 ........ Gs ........ 36005 .... meter per second squared

Excel file available on request

I have heard from a reliable source that loose breech should never be more

than .008. The slide recoils and really slams the lugs at this distance. I

like the hood and breech face touching for accuracy and longevity.

Quote:

Based on my calculations in the post above, a clearance of 0.008" should

result in an impact velocity of about 12 feet per second. That is like

dropping the slide form 2'1" and having it stop on the locking lugs.

subscriber - First, it's very, very clear that you are WAY farther along

the learning curve than I am. That being the case, may I pick you brain a bit?

First, I'm not sure I understand why having a gap between the hood and

breechface would help keep lint and mud out instead of allowing it in. Seems

like having the hood fit to the breechface would help keep foreign matter

(from external sources) out, and as for internal sources, wouldn't most of the

fouling (from firing) be nearer the front of the port, and go more out and

down (especially because of the hood), for instance into the rails?

Also, I don't understand this part: "If the hammer is almost resting on the

nail, you cannot get enough of a swing to generate an effective blow. If the

gap is 6 to 12 inches you can whack it. The slide is a little lighter than

that one pound hammer and while it is accelerated by thousands of pounds

rather than your hand, we are arguing the difference between 1 and 10

thousands of an inch - not much of a running start." But, the hammer IS

already against the slide when the slide starts back under recoil. That being

the case, I don't see how the slide makes a "blow" on the hammer to start it

back, but only builds pressure until it (and the hammer) start to move

together. Am I readin' that wrong? (If not it won't be the first time I've

missed the boat. lol) [/QUOTE]

Jon, he's speaking about different hammers I think. Using an analogy to

illustrate the difference in forces when the hood is hard fitted vs "a gap".

No gap, the slide doesn't have free movement to batter the lugs, a gap, the

slide has a little bit of free movement so it can gain momentum. When that

momentum hits the lugs on the barrel, some of the energy gets taken up by the

lugs, potential battering of either the barrel or the slide. The nail part,

picture a framing hammer sitting in contact with the nail, try to hammer the

nail in. Very difficult. But raise the hammer 12 inches and let gravity pull

it down to the nail, you generate lots of force. The second part of that,

substitute "slide" for "framing hammer" and "lugs" for nail.

Your other question, perhaps think of it this way. A minimum sized chamber

will work, but if you get a long but still in tolerance case, it may not go

into battery. Shoot a few thousand rounds without cleaning, you may get gunk

buildup that effectively shortens the chamber more, leading to greater

potential for problems.

So yes, a gap may let stuff in, but it may also let stuff out.

This is just my understanding of what he's written, I could be completely

wrong in the way I interpreted it.

As usual subscriber likes to consider the hypothetical instead of the

actual. I do also like to consider the hypothetical when the actual doesn't

exist, but in this case it does. Less than .001" clearance between hood end

and breech face when barrel is as far forward in the slide as possible is

goal. The barrel going into battery rises on the breech face with zero

clearance and has a self cleaning action. Have never seen anything be able to

block closing to battery during live fire. Consider the point if the gap is

greater, then a bigger piece of lint will block it also. Silly huh!

From what I read, I think I need a new barrel fit because the gap between the

bolt face and barrel hood is about .015". Quick question, will it help to seat

the bullet longer so that the base of the case is against the boltface? I know

this is not the ideal, but this pistol is not a target pistol, but my defense

weapon. It functions very well and the barrel locks up tight with no wobble.

Good thought, just don't do it. Seating a bullet long to tighten up the breech

to hood gap isn't a good idea. For this to have an affect the bullet would be

contacting the barrel lands and holding it forward in that manner. Pressure

spiking would be my first concern. If the gun shoots fine and you're happy

with it that's fine. Production guns are loose, it gets them in a box and out

the door quicker. Besides the possible battering, accuracy suffers as the

barrel is bumped by the slide coming back and making that contact with the

radial lugs before the bullet has left the building. It isn't unsafe just not

as accurate as it possibly could be.

Quote:

Jon, it is normal for the breech face to contact the end of the barrel hood

when in battery because the recoil spring takes up the "slop" and transfers it

to the locking lug engagement. The gap at the hood opens up on firing and

results in the slide's locking lugs impacting the barrel's lugs with some

velocity - the larger the slop, the larger the impact velocity.

As such, there is no difference in the propensity for external dirt to get in

between the hood and breech face on a tight gun than on a sloppy gun when in

battery. The difference comes in to the ability to handle dirt that comes in

during the firing cycle, generated inside the gun and from the environment.

If you cannot close the slide on a small shim between the breech face and the

barrel hood so that the hood to lug gap is essentially zero (stated as ideal

by many here), the gun risks jamming from being fired rapidly just due to heat

expanding the barrel so that the alignment of the barrel lugs no longer

matches the slide lugs. Yes, the slide heats up too, but the barrel heats up

first because that is where the powder is burnt.

The hammer I confused you with is not the gun's hammer, but a hammer you

might use to drive nails into wood.

Thanks for the comment LM. I figured as much. Guess I will send it in this

winter and have it fixed. In the mean time screw my seater down a little.

Quote:

Log, the gap between the barrel hood and breech face is 2 inches every time

the gun is fired. This could allow in some pretty large pieces of crud, should

you have to fire from a position where you are immersed in leaf litter or

other dirt.

Now if the leaf fragment that just got caught between the barrel hood and

breech face of your gun is much thicker than the 0.001" you advocate, your gun

will not go into battery and if this is a "live fire exercise", that could be

a real problem. To check for this, create a leaf fragment analog by placing a

piece of paper 3/8" square on your tightly fitted gun's oily breech face

and notice that it does not fall off. Now, close the slide. If you have a

0.001" potential gap at the hood, the gun will not go into battery because

the 0.004" thick paper won't allow it.

No matter how large the lug battering gap discussed in this tread opens up to

on firing, the hood should be in contact with the breech face when going into

battery. As such, the self cleaning action you describe is not lost - with a

larger hood to lug clearance the gun can wipe at the same piece of dirt

several times rather than jamming on the first try. Also, as the "gap" at the

hood is closed when in battery, it can't allow in a larger piece of lint with

a "loose" gun.

As mentioned above in another response, if you rapid fire your gun, that

0.001" closes to nothing when the barrel is 100 degrees Celsius hotter than

the slide. Calculated from coefficient of thermal expansion obtained from http://www.engineeringtoolbox.com/linear-expansion-coefficients-

d_95.html, assuming the distance from the barrel hood to the locking lug

with the tightest gap is one inch.

Quote:

So, you are suggesting that when you force locking lug contact on production

guns, a gap much larger than 0.001" between the barrel hood and breech face is

normal? Why then this insistence on an unrealistic standard?

While a tightly fitted custom gun may loosen up a little initially, why would

you take a combat pistol and potentially compromise its ability to work in its

expected operating environment; unless you are turning it into a dedicated

bull's-eye gun for shooting at paper target only?

So the point that this response is based in hypothesis only and not in actual

experience doesn't mean any thing except that you have an opinion that is

contrary in nature to actual experience.

You think or state that .005" is better, so if an object would block a .001"

gap from chambering why wouldn't an object .004" larger block a .005'' gap and

are those object really that much less likely to be in the environment?

The larger gap serves one purpose, it's easier to produce, and why production

guns have up to .015" gap.

I have yet to hear of or experience any stoppage based on a foreign material

entering the hood end to breech and stopping function. And to suggest that

.004" greater will alleviate this fictitious bogus concept is down right

funny. Keep it up I'm laughing myself into taking you off my ignore list as

these concepts based solely on conjecture are very entertaining. But then no.

I think the point of all this conjecture is to make a distinction between guns

used for competition and guns carried for defense, especially in actual combat

environments. It is the difference between a gun that is fired a lot in

competition and not carried, and one that is carried a lot, but fired only a

little.

If you want experience to bear on the subject, ask WW2 vets how much slop

their guns had in every dimension and how robust they were to jamming in the

worst environments. Now explain to them that the 8 inch grouping standard at

50 yards for the GI pistol wasn't good enough, and that their combat pistols

should have been accurized to National Match standards.

I understand the perception that tightness represents value. If I had my car

engine rebuilt I would want the bearings and the piston to bore clearances so

tight that they are on the edge of risking seizure, thereby promising the

longest possible wear life - why rebuild and engine with so much slop in it

that it starts its new life already "worn out"?

I could just as easily accuse you of being overly theoretical with your

insistence on less than a 0.001" gap when practically speaking this is not

only expensive to achieve, but has the potential to tie up the gun when the

chips are down. I have never heard of a 1911 pistol failing in any way due

solely to a hood to lug gap that measured 0.01". Have you?

Considering your high standards, what do you think of the fact that the

average production pistol only has locking lug contact between barrel and

slide on one of three lugs? I consider this more than a theoretical problem.

Quote:

Accuse if you wish, but the tight fit is a point in accuracy, and that isn't

theoretical, but proven on the firing line. You make a good point, no, 8" @ 50

yds. isn't acceptable. The cost of a barrel is the expense, fitting tight or

loose isn't, it's the same. Albeit the desire and patience and knowledge that

it does make a difference. What isn't defensive about accurate?

Quote:

No! And good point, nor any failure attributable to .001" so, I'll take

accuracy over a sloppy production fit.

This thread is a lot to read and some is difficult for me to visualize and

comprehend.

If this was previously stated forgive me - I didn't see it and thought it was

pertinent. I've had excellent accuracy and durability with the Kart EZ fit

barrels.

Here's what Fred Kart has in his instructions for the Kart EZ fit barrel.

"As the hood starts into the recess. observe that there is clearance on both

sides of the hood. If there isn't, remove material from that side of the hood

until there is a minimum of .003" clearance. There is no maximum clearnance,

except that it probably shouldn't be more than about .010". The hood merely

guides the barrel into position so the pads can do the final positioning just

before full lockup."

Later it goes on to say:

"File the end of the hood to match the breechface (some aren't square) until

the barrel can be moved in and out of lockup position without force. A

clearance of .001" to .002 is ideal. The feeler gauge (the feeler gage that

comes with the barrel fitting tool kit is .003") should not go between the

hood and the breechface, but it is important that the barel can be moved in

and out of lockup position without "sticking". "

There you go and I haven't heard of a single barrel maker say otherwise in

regards to an oversize barrel fit. Better is always better. Today's guns

differ from the mass produced war guns in that being able to swap parts in the

field with a reasonable certainty that it will work without any fitting,

needn't be the controlling factor, thankful for that.

A 'zero tolerance' and sticky fit will open as the lugs seat. Usually

within 100rds.

I fit to achieve non-sticky, full contact and expect it to be .001" or so

after test-firing.

Log Man; Thanks for posting the drawings. I worked as a draftsman and

engineer for many years, and drawings I get! I finally see what you're saying

about the 52 min. angle. In fact, I can see the angle at the muzzle; looking

across the muzzle (side view) and drawing the slide back, the muzzle is

parallel to the bushing - as the slide returns to battery, the slight angle

becomes apparent as the lower edge of the muzzle is closer to the bushing than

the upper edge. As for barrel hood contact, three of my four 1911s will grab a

very thin piece of paper between the hood and breech face when slowly closing

the slide on it, including the Taurus! The only one that has a little more

clearance is a 1953 Gov Model with a new Colt barrel from the correct time

period, and it will grab a strip of typewriter/ printer paper. Very

interesting stuff! Checking out the 1945 Remington Rand, 1953 Colt and 1983

Colt, I see that the top of the rear sight is slightly higher than the top of

the front sight, resulting in a counter tilt of the slide and frame, canceling

out the tilt of the barrel and making it more or less parallel to the line of

sight (with the correct sight picture). There is probably more 'tilt' built

into the sights so the trajectory crosses the line of sight at a reasonable

pistol range, maybe 25 yds. Now I can't wait to get back to the range and find

out where that near-zero is on my pistols.

Well I'm glad the penny dropped and it makes more sense to you now. It was

LogicGS that posted the picture after my verbal explanation. So thanks to him.

Quote:

"File the end of the hood to match the breechface (some aren't square) until

the barrel can be moved in and out of lockup position without force. A

clearance of .001" to .002 is ideal. The feeler gauge ( the feeler gage that

comes with the barrel fitting tool kit is .003") should not go between the

hood and the breechface, but it is important that the barel can be moved in

and out of lockup position without "sticking". "

Yes, you can remove metal with a file, but you cannot put it back...

I am sure that a barrel with such a close fit will last a very long time -

assuming that you have solid locking lug contact on more than one lug.

Otherwise, this tight fit will tend to open until greater lug contact is

obtained by peening the tallest barrel lug down to match the others.

Quote:

Sweeny said in one of his books that expedited wartime manufacturing meant

making slides soft, in other words, those guns weren't expected to hold up to

50K rounds, probably 20 rounds total would justify their expense as that would

mean someone was still alive. Any gun that got worn out could be replaced, or

repaired by an armorer in theater. So, I sincerely doubt that anyone spent

much time worrying about longevity.

This thread, folks, took me hours to read and understand. I read it last

night, and realized I'd have to come back to it. Today I read not only every

word but also every related thread listing. I also spent some time with J.K.'s

books, trying to visualize the geometry involved. I had no idea how little I

knew about the subject! A totally awesome thread folks!

On the subject of hood versus barrel face to breechface fitting, it occured

to me that with the hood in contact eliminating excess play in the locking

lugs the angle of the locating line is longitudinal to the lug surfaces, or

very nearly so, that is to say that if the hood pushes the lugs into contact

or near contact with the rear of the slide lugs it does so on the same plane

as the opposing movements, whereas if the barrel face is used for the purpose

then the push is at an angle, at least at a much greater angle than can be

gotten from the hood contact.

I'm not sure what effect that would have except that intuitively a straight

line setting seems more sure than an angled setting, probably because it

eliminates any barrel springing (from a tight bushing at the front of the

barrel) from effecting the lockup.

Uhhhhhhh... so, do you propose clearance, Clarence? If so, how much?

Quote:

Don't you mean peening "the next closest barrel and slide lug combination

together" not "tallest down?" - horizontal movement, not vertical?

I have only 6 1911's in my safe. I decided to check them all with shim stock.

Go No go

RIA 1911A1 (New) .0025 .003

The Colts did very badly, I was amazed. And I was surprised by the RIA, I

thought it would be sloppy, considering what I paid for it.

4 pistols from 3 different manufacturers within .0005" of each other?

What are the odds?

Yeah! I recognized that too. Those were done with shimstock noting the last

size that the action would close up on, and then the size that it wouldn't.

That Officers kinda freaked me as I kept trying larger and larger shims. I

guess I shouldn't shoot it until I replace the BBL. Same with the other Colt.

Quote:

"Down" here is meant in the sense of a reduction or towards a smaller value,

rather than towards the center of the earth's.

Quote:

You were perfectly happy shooting these guns until you measured them. Do the

barrel lugs show any unusual peening? If not, what is the rush to change the

barrels?

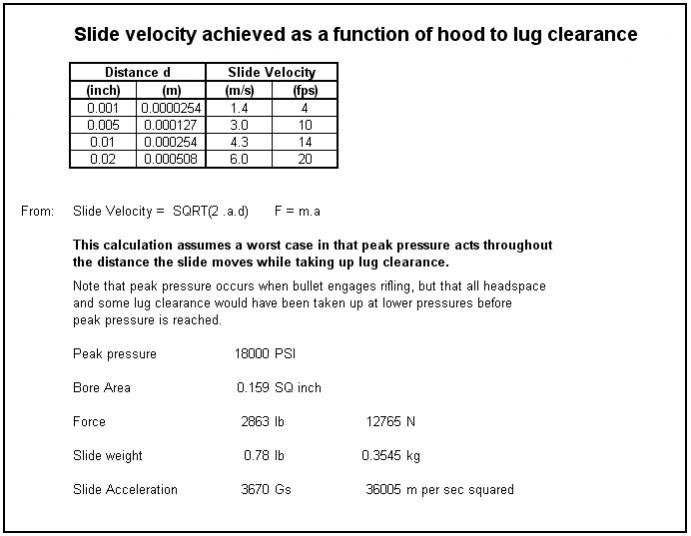

How do these Colts' slides and barrels compare to the original blueprints?

See screen captures below from

www.m1911.org/blueprints/blueprints.zip

One level up at

http://www.m1911.org/technic.htm

Also at

http://files.weaponryonline.com/blueprints_scans.pdf

I don't have a Rolex either, Sub. Just trying to say that over a period of

time, with the lugs slapping, damage can occur.

Quote:

Well, I can't agree, can't keep my mouth shut, and I am with Log. As he said

once already "hypothetical, rather than actual".

Over 30 years in LE were torture testing various weapons for evaluation

involved ridiculous extended periods of sustained fire, never, did I witness a

pistol sieze or experience a stoppage from "thermal expansion"... For 20 +

years our agency utilized Sig pistols, which are manufactured with hard

contact between the hood / breech face, and a single locking lug. I never

witnessed stoppages from any kind of debris, firing residue, or excessive

heat. True fighting pistols... with tight tolerances...

Camp Perry is a proving ground that precision pistols are extremely accurate

and reliable.

Quote:

I didn't buy either of these Colts new, I assumed the Commander was near new

as I was told that, but now I wonder. The owner had changed out the grips and

was a gunshop owner, he may have swapped out the barrel.

I bought the Officer's from an old guy, no idea how many rounds or the

history. Buy hey, that .017 is way excessive! So, Now I'm wanting a set of

headspace gages, and probably a new barrel, and I'll swap barrels on the

Commander, but where can I find bargains on a stainless barrels?

Quote:

Bargain stainless barrels... aren't bargains. While Bar-Sto and a couple

others are quality, the best, IMO, are the Wilson barrels as they are made

from 17-4 PH stainless. So stainless, I buy Wilson. Carbon, I buy Kart.

Well, I can't believe this, I took the Commander apart. The assumption was

that if the bareel hood accepted .011 and failed to lock up with .012 that

there is .011 slop in the locking lugs, but no! This gun does contact the LH

side of the side of the barrel face against the breech block side, the RH side

shows about .002" light (Guessing) while the hood has all or almost all of

that .011" gap showing even if I push the barrel back hard. It appears that

whoever set this gun up did it Brickeyee's way! Yep! The Officer's is set up

the same way, big built in gap! (.015-.017")

2 out of 6 are gappers. This is interesting stuff.

I checked my Star A model too but couldn't get the shim stock in it as the

guideblocks are much narrower than the shimstock for 9MM Largo. Two pieces of

paper wouldn't stop lockup though.

Quote:

Long ago and far away there was an issue with the S&W Model 59 and a large

amount of Blazer aluminum cased 9x19 fired fast and furiously - maybe not a

realistic scenario - and the trigger would lock up - presumably from the draw

bar binding in the frame - tentative conclusion was that the aluminum dumped

heat in the pistol that brass carried away and because the issue - as opposed

to training - load was brass cased - and gave no such issues when tried - it

was not an immediate action item. Talk of lubes and clearances and referred to

Speer and S&W and I never heard more about it.

Vaguely more related I'd heard that the final seating on all 9 lugs of a

Weatherby Mark V action started with blue pill proof loads?

The BarSto merchandising DVD doesn't say a lot about hoods on the 1911 but

does surely make the point that they vary more than most people know.

Quote:

Just to confirm "hard contact"; that means if you take the barrel & slide

assembly off the frame and push the barrel forward as far as it can go, there

is no gap between the barrel hood and breech face? Contact between barrel hood

and breech face is always hard when assembled and in battery due to the recoil

spring.

Hard contact would mean the barrel makes contact with the slide at both the

breech face and the locking lug simultaneously - is that what you meant?

Quote:

A new barrel may not solve your problem - it could be the slide dimensions

that are off with the locking lugs too far from the breech face. Or maybe

both...

Slide lug specs:

Barrel lug specs:

Quote:

As posted, the barrel is fine, evidently whoever fit it did so from the lower

barrel faces to the guide block surfaces. I found a post by someone here that

said Colts have always been fit up that way. I can't find it now. IMHO the

correct way is from the hood, as it's a straight line behind the upper lugs,

and I don't see why anyone would do it the other way. In both of my Colts the

lugs are reasonably tight in the slide in spite of the gap.

It is sadly common practice or has been common practice for Colt to grossly

over cut the lower lug and hood as this means in factory assembly that any

barrel will fit any slide and frame, no fitting, out the door. A new barrel

with the GS Fit designation will be able to be correctly fit to this frame and

slide. Reality has shown this to be both common and correctable with a new

barrel.

To answer parts question I don't recommend a cheap bargain barrel as that is

what you now have. I would only recommend a GS fit barrel not any of the drop-

in or semi-drop in barrels advertised. My choice in SS would be a Schuemann

barrel.

quote:

Yes, sir...

Like two Jo-Blocks sliding together... zero clearance.

I understand and respect your point, and I have no issue for you or the smith

who wants to run some clearance. It will work just fine. But I, many other

smiths, and some manufacturers have built them with zero clearance for

decades... and they work just fine.

Thanks for your input, sharing and comparing is how we all learn.

I can offer two points of view: First as a user of fine Bullseye Pistols with

an Expert card (working on Master!)and second as a hobbyist at home with

some common sense.

1) On my Bob Marvel Ball gun, he made it a point to write on the final build

sheet that the hood to breech clearance was less than .0005. My KC Crawford

built wad gun and Rock River Wad gun have no daylight between the hood and

breech face but unlock with ease and no "snap". Clearly this is done by

design. There have not been any failues of any kind with these guns, even when

it's 115 outside in Phoenix. I believe I recall George Smith writing that a

gap over .001 will result in groups enlarging on paper at 50 yds. Some people

say "So what?" and "who cares about 50 yd groups?" Point is that there does

not have to be any compromise with functionality and accuracy at all, so you

should not have to accept any compromise. Don't want to start another thread

or get of topic, but that's my opinion based upon my observations.

2) It just seems to make sense that (during recoil) the slide pushes the

barrel back and then down instead of slapping it down

A SIG is closer to a 1911 than this rifle, but it shows an instance of where

the tolerancing strategy includes the prevention of heat induced jamming:

"If you make the receiver/bolt area too tight, after thermal expansion caused

by firing, they stop working. So this is a very critical area, Ritchie adds."

From http://www.sme.org/cgi-bin/find-arti...20011011&&SME&

Here are some clowns wasting 1000 rounds of .45 ACP in 10 minutes trying to

overheat a 1911:

http://www.downrange.tv/show1/index.htm. Start with video #3 or 4 to save

some time.

It is impressive that the gun did not jam, but notice that no one proclaimed

anything about accuracy or wear at the end of the "test".

How much does the temperature rise per number of rounds fired? See

http://www.brazoscustom.com/magart/0611.htm

BigJon

07-15-2009

Interesting. Everything that Marvel said is correct as I understand it.

What he didn't explain is why it's important in regards to what happens when

the gun is shot and the slide tries to recoil and is held by the bullet

dragging the barrel forward.

wrcamp

07-15-2009

LogicGS

07-15-2009

As mentioned, a great thread, if one can keep the terminology for all the

parts and pieces straight to understand what's being imparted.

.904 to .923

log man

07-15-2009

Jerry Keefer

07-16-2009

BigJon

07-16-2009

log man

07-16-2009

BigJon

07-16-2009

If you look down at the top of a factory gun with the barrel in battery and

see a slight gap or even full contact between the back of the hood and the

breech face, does that automatically tell you that that radial lug spacing has

been optimized?

How far apart must the radial lugs be before it's considered "bad"?

saltydog452

07-17-2009

saltydog452

07-17-2009

BigJon

07-17-2009

log man

07-17-2009

BigJon

07-17-2009

Why is it more logical for the guide blocks to make contact, except for the

fact that they are second inline if the hood doesn't. Something to think