I have a Kimber custom II that was purchased less than 2 years ago. It has had less than 3,000 rounds through it, and I changed the recoil spring out at about 2,000 rounds.

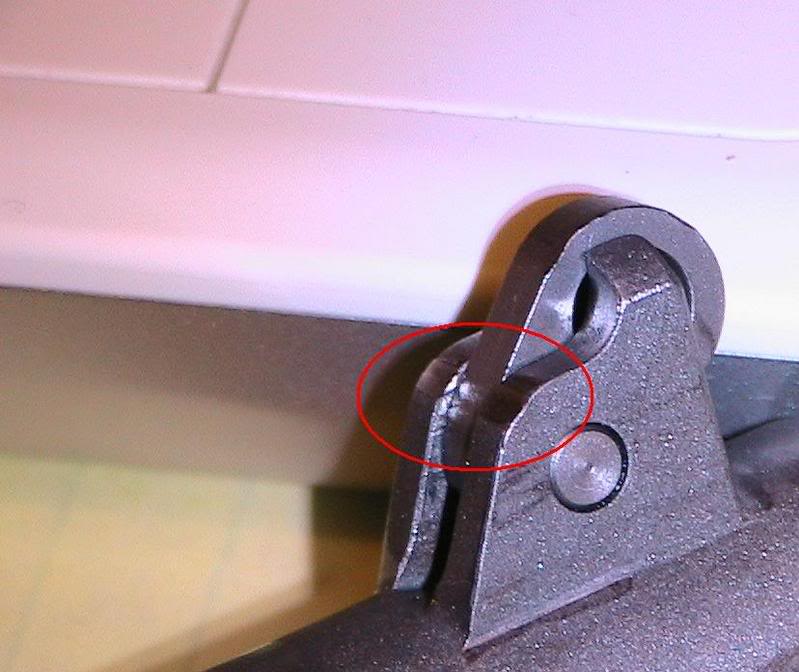

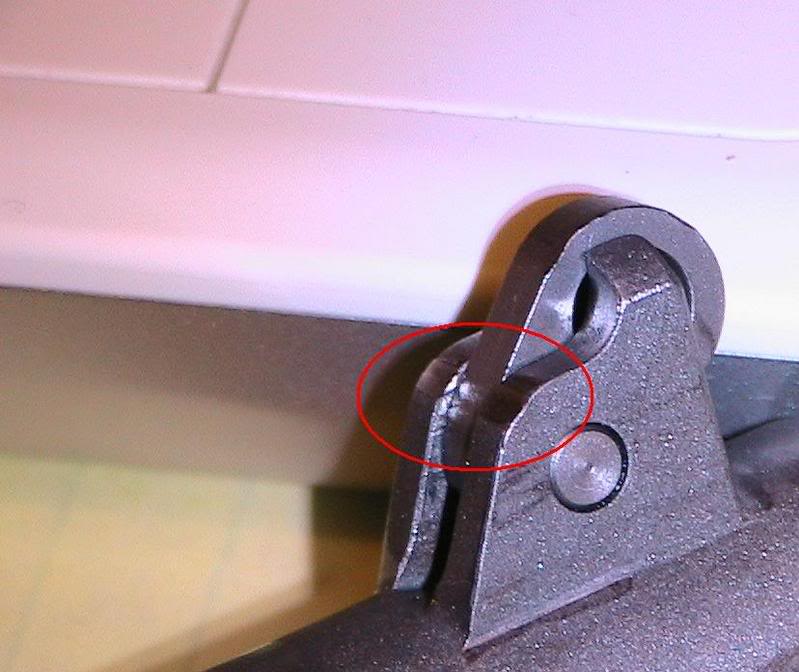

It seems to feed and function just fine, but I have noticed that the portion of the barrel that contacts the slide stop (the twin "s" shaped lugs on the bottom of the barrel which hold the link are beginning to get a slight concave depression in them where they contact the slide stop.

Is this normal? If not, what causes it, and how can it be fixed?

The slide stop is hitting that area as it goes into battery. On the guns I build I relieve that spot. Take a small file and remove metal in just that area until the slide stop goes over without touching. Its easier to do if you remove the link.

Thanks for posting those great examples of what I call "barrel bump". These spots are where the slide stop bangs into the lower lugs when the barrel is moving into and out of battery. And, no, those marks should not be there. Yes, they are a sign of poor barrel fitting.

Referring to a recent thread, barrel banging like this is usually what happens when you use a lug cutter as your one and only lug fitting tool. You must then use (your choice of tooling) a rotary table and vertical mill to make a true radius on the lugs...or simply sculpt the lugs with a scraper, sandpaper and files to the proper radius.

Glad to hear the gun is working ok. The bump marks are telling you where the interference is and you can do a little smoothing in that area, using the slide stop pin as a guide. Most of the time the interference causes erratic feeding and ejection problems that can't be pinned down exactly. Sound familiar? This is one of the culprits.

Well, thanks for the replies and information. I'm not a gunsmith, but I do like to tinker with simple tasks. I have built a couple of AR15's, but that's nowhere near as involved as making a 1911 tick from what I've read here. One day I hope to have a room with some machine tools, but I have so little time to devote to that right now.

As far as removing the link, it's staked, and I have no tools at all where I am (on the road for work 2,000 miles form home). I could probably give it a few swipes with some fine wet or dry wrapped around a drill bit, but I would rather give it to a smith. Trouble is, I am unfamiliar with the area. Does anyone know of any good 1911 smiths within driving distace of Williston, ND?

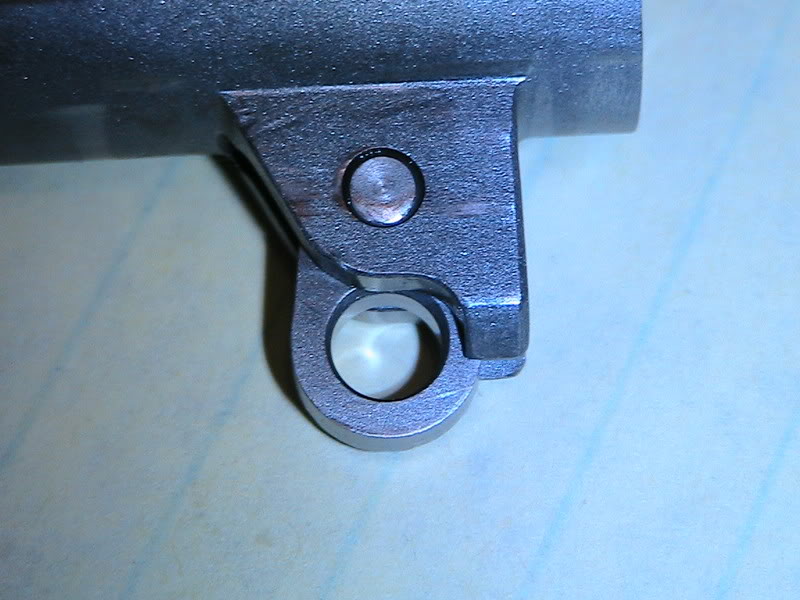

What's the condition of your slide stop?

It appears to be perfectly round. It's one of the Kimber MIM parts. You can see where the finish has been rubbed off where the lugs contact it, but beyond that there doesn't appear to be any damage. I'm not sure that the finish rubbing off means that substantial damage to the slide stop has occurred, since the finish is also coming off somewhat on the sxternal portion of the slide stop where it touches my skin.

I did find out that cold blue apparently does not work on MIM parts while trying to touch up the slide stop and safety.

Well, as Lazarus said, your barrel legs don't look good at all. You should have that fixed. What recoil spring are you using in that thing?

Upon a second look, it does appear to have slight wear on the slide stop.

I don't remember the weight of the spring, but I do remember looking through bag after bag to get the weight Kimber recommended. I think it was 18lbs., but I could be remembering wrong. I have the bag the spring came in at home, but that's no use to me here.

So, I guess the next question is what can be done to fix the problem from a hotel room with improvised tools, short of mailing the gun off?

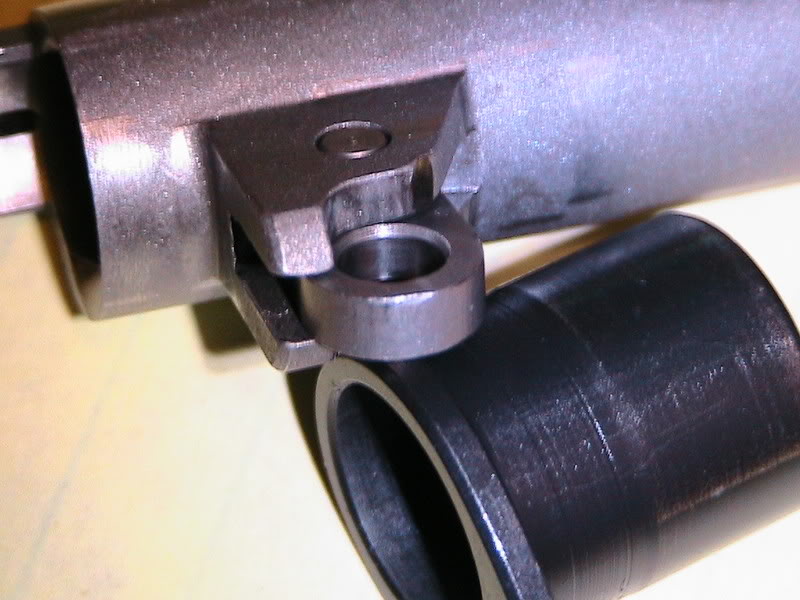

Upon closer examination, I can see some wear on the outside of your link as well. Is it real, or are my eyes playing tricks on me? Also, show us who the slide stop hole looks in your link.

Nope, you are correct. There are a couple of spots on the outside of the link that have little dings. I am not sure if this happened while firing the gun, or if it happened during assembly / disassembly, or if the barrel was dropped. I am the second owner of the gun. The first owner is a friend, and he did drop the slide on concrete while spraying it with gun scrubber once. The only apparent damage was a slight stippling (almost imperceptible) on the spring cover portion of the slide, and a small pit that looked like it had been made by a center punch on the bottom of the left hand rail on the short portion of the rail rearward of the notch for the safety.

Back to the link, in the pictures below, you can see the dings on the outside of the link. There are no corresponding marks in the frame that I can see. Although, with the link pushed all the way forward and lying against the barrel, there is a little ridge on the barrel at the front of the channel the link rotates within, and it looks like that ridge makes contact where the ding occurred. Another ding that is located right in front with the link lying against the barrel. Both of them probably can be attributed to the time I assembled the gun and missed the link with the slide stop.

With the slide, bushing, barrel and slide stop assembled (sans spring), you can feel the resistance as the legs ride over the slide stop while cycling the slide manually.

Also evident in the pics is that the link is apparently too short to allow the slide stop to clear the radius on the front of the legs without binding. What I don't understand is why it appears to impact hard in that area.

Finally, if I can remove some of the material from the legs to allow the link (and slide stop) to clear them, will that have a negative effect on how the barrel locks up?

If you remove only at the area where the problem shows, no, it shouldn't affect anything. Also file down the dings on the link. If you pass the slide release in the link, it shouldn't make contact with that front edge of the legs, only when the link/slide release is pulled all the way to the rear the slide release shaft should touch the barrel's legs.

Before you do anything drastic, wait until 1911Tuner jumps in here, he is much more experienced than me on fitting barrels etc. I'll draw his attention to this thread.

Ok, thank you very much for your help. I'll let it sit for a while and wait for him to weigh in as well. The biggest problem I forsee is removing the link. Can this be done with a pin punch? I don't have access to a press here, or at home, for that matter.

I do not think it is necessary to remove the link. You can do the filing with the link pulled all the way to the rear. You will need it to make sure there is no interference at that spot, anyway.

Quote:

Also evident in the pics is that the link is apparently too short to allow

the slide stop to clear the radius on the front of the legs without binding.

What I don't understand is why it appears to impact hard in that area.

Could be a short link... Could be the lower lug's radius... or it could be a spec or tolerance stack issue.

Check for short link:

Dress the damaged area smooth and follow the radius as closely as you can. Remove no more than necessary to get the slidestop pin out of a bind.

Assemble the gun with the slidestop arm hanging vertical and the recoil spring plug out to free the spring. Slide full rearward... push the barrel rearward firmly and see if the slidestop will swing free or if it binds. If it binds, it's probably a short link.

Ok, without doing any work to the legs, I tried the check 1911Tuner described.

With the plug out and spring freed, I have the slide held fully rearward. Pushing back on the barrel, the slide stop swings back and forth like a pendulum. I can't get it to bind.

So, all that is left is to remove a little material to clear the slide stop?

If so, I do have a fine grit diamond shaprening stone. (Perhaps sharpening steel is a better description.) It's a round tapered one made by Smith's. It tapers from about 1/4" to about 1/32". I am sure you guys are cringing at the thought of using such a thing, but at least it offers a measure of control that the dreaded Dremel tool doesn't.

Quote:

So, all that is left is to remove a little material to clear the slide

stop?

Excellent news. It'll be a fairly simple fix. If you can find a lathe blank, you can use it to scrape the area that's putting it in a bind.

Gee, it's a good thing I browse this forum some. My widebody RIA has the same thing, with more wear on the slidestop pin itself, somewhat larger flattened/beaten areas on the legs, and the reason I took a look in the first place, a shiny "bar" mark across the link - can't quite feel if it's actually out-of-round there, not with these meat-hooks. (With barrel inverted, stop pin inserted and moved as rearward as possible, mark is approximately in the 1:30 position, breech-to-right.)(Yeah, I know, "troubleshooting is bloody difficult without pics", going to hit up a friend to take a bunch of various ones this week.) Appears to correspond (link forward to lower-leg impact area) to similar mark at the bottom of the link-slot in the frame - leg hits the stop- pin and the impact jams the link down?

Hmmm. This would seem a bad thing to keep shooting with, and a good thing that I have a warranty, yes?

OK!

You guys with Kimbers that have fired over 1000rds, pull 'em down and have a look.

I'd bet dollars to dognuts that 80% of them, manufactured over the last 5 years, exhibit the same peening.

My 'standard practice' is to relieve this area on all Kimbers that lie upon my bench.

Quote:

Excellent news. It'll be a fairly simple fix. If you can find a lathe

blank, you can use it to scrape the area that's putting it in a bind.

By "lathe blank", do you mean a tool bit blank? I've been wondering when you and others have talked about "scraping steel". I've never done that. I do use a wood scraper a lot, but that is likely to be pretty different.

Please explain and describe this type of scraper a bit for me and others. Wood scrapers are terrific tools.

Quote:

By "lathe blank", do you mean a tool bit blank?

Yep. I routinely use Brownells' disconnect scrape... which is nothing more than a HSS lathe bit mounted in a screwdriver handle to do it, though I much prefer a triangular file with the teeth removed on a belt sander. All the files that I've been using are dull, and I don't have easy access to a sander any more. So...

Quote:

You guys with Kimbers that have fired over 1000rds, pull 'em down and have

a look.

Thanks for the info. I have 3 Kimbers now. I haven't had the chance to look at the other one that has seen a good amount of use. The one in the pics is a Custom II with approximately 2,500 through it, IIRC, and I have a TLE II (external extractor) with about 1,200 rounds through it. I'll need to look at it next trip home. I just bought an Eclipse less than a month ago, and it hasn't even been to the range yet.

Hi David: Wood scrapers aren't for steel. The type of scraper 1911 Tuner referred to (made from a triangular file) is what most store-bought scrapers are shaped like. Sometimes in industrial supply catalogs they're listed as "bearing scrapers". If you have a hand-powered rotary deburring tool, most makers also sell scraper blades to fit their handles, but they'll rotate in the handle just like a deburring bit. Their rotation may make them harder to control - maybe not. Never used this type.

I knew the wood scrapers would be too soft. Thanks for the further info on metal scrapers. Yes, I use the hand operated swivelling deburring tool all the time. And I do think control (for me) would be better with a solid handle.

I've got some HSS lathe bit blanks, and several old worn out triangular files. I'll just need to stick on a handle and try it.

Scrape

In a pinch, you can use the blade on a good pocketknife, but if you're not careful, you can gouge the metal too deep.

Well, I removed some material with the diamond stone and took it to the range today and fired 50 rounds through it. I was afraid to remove too much, and the link was getting in the way, so I couldn't take it down as far as I would have liked.

After disassembling it for cleaning, I inspected the feet, and in only 50 rounds, the peening had reappeared.

I need to figure out how to remove the link using improvised tools in order to get to the high spot.

Ok, so I figured I'd post an update, seeing as there is a recent post in the Kimber forum from a user with what sounds like a similar problem. I did, in fact, get a chance to look at my TLE II, and it does exhibit the same peening on the lower lugs. I have also smoothed out the battered area on the lugs of the Custom II (the barrel in the posted pictures). After several range trips, the peening has begun to reappear. I am sure this is because I have not yet had the opportunity to use the appropriate tools to really dress up the lugs properly.

I hope this thread helps in the diagnosis of the other members problem, whether or not it is indeed the same.

If the peening is on the front of the lug... right at the curve... the lug is oversized and needs to be reduced in order for the lug to roll smoothly over the slidestop crosspin.

Correctly fitted... lug and link... the pin should evenly contact the link ID and the lug radius, with slight bias on the link... riding of the link maybe .003 inch... for the first few degrees of the arc. Once the pin is past the curve... it should all be on the lug.