Had always wondered what the official U.S. Army spec for the "headspace" in a U.S.G.I. 1911 was and stumbled across what I thought was the answer in our Technical Issues section, as shown below:

PICTURE 404

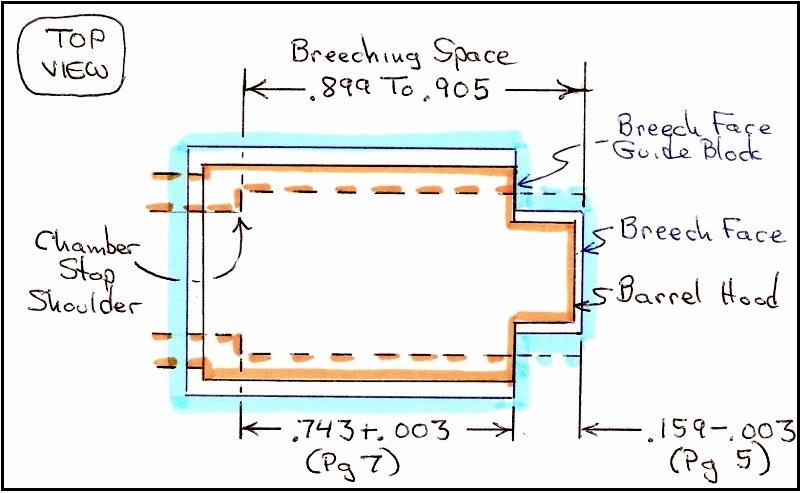

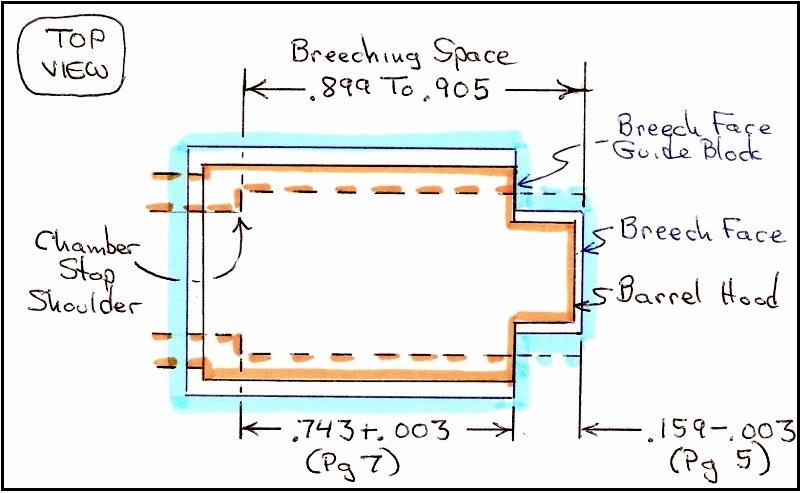

The upper limit (0.925 inch) seemed kind of excessive, so blueprint data from the same era (early 60's) for the barrel and slide was used to calculate this dimension. The result was 0.905 inch, as shown below:

The difference between these upper limits is 0.020 inch, which seems way too much for this rather important dimension.

Seems like either this U.S. Army blueprint dimension is in error or I don't know how to figure out stuff like this anymore (or maybe a little of each).

I'm stumped. Anybody got any ideas?

Static headspace dimension limits are .898 to .920 inch. GO and NO-GO gauges reflect these limits... but those dimensions are absolute minimum and maximum tolerances.

i.e. The gun should go to battery on the GO gauge, and should not go to battery on the NO-GO gauge... so it would appear that the limit on that end would be something less than a .920 static dimension.

I've gauged a few that appeared at first glance to go to full battery on the .920 inch NO-GO gauge... but closer examination revealed that the slide fell short by as much as .003 inch, and although the disconnect had attained full reset and the gun would have fired... the maximum headspace limit hadn't quite been reached. Although they were technically acceptable/serviceable pistols... an armorer would have... and should have... rejected them for excessive headspace... and I did.

"Click"...

is the sound of the little little light coming on in my head!

The calculated 0.905 inch max applies to brand-new (not worn) barrels and slides when the gun's in battery with the barrel as far aft as it'll go in the slide.

The 0.920 (or 0.925) inch is then the upper limit after the parts are worn and the barrel is as far forward as it'll go in the slide - such as when a nogo gauge is inserted.

That makes perfect sense, I guess, because the upper endshake limit for a U.S.G.I. 1911 works out to 0.020 inch from blueprint data. This plus the 0.905 inch gives the 0.925 on the blueprint.

There's a circled letter A next to it on the blueprint, but nothing on the print explaining it. Maybe it was all this, eh?

Quote:

The calculated 0.905 inch max applies to brand-new (not worn) barrels and

slides when the gun's in battery with the barrel as far aft as it'll go in the

slide.

The 0.920 (or 0.925) inch is then the upper limit after the parts are worn and the barrel is as far forward as it'll go in the slide - such as when a nogo gauge is inserted.

Quote:

The calculated 0.905 inch max applies to brand-new (not worn) barrels and

slides when the gun's in battery with the barrel as far aft as it'll go in the

slide.

The 0.920 (or 0.925) inch is then the upper limit after the parts are worn and the barrel is as far forward as it'll go in the slide - such as when a nogo gauge is inserted.

Well... Almost.

The clearest definition of headspace is the difference between the static dimension... breechface to chamber stop shoulder with the barrel fully forward... and the length of a cartridge case with the gun in-battery.

F'rinstance...

A static dimension of .905 and a cartridge case length of .895 provides .010 inch of headspace. Defined as live or "working" headspace... it changes with every round chambered unless all brass is exactly the same length. Static headspace dimensions only change with wear and/or lug deformation.

As far as the dimensions of the standardized gauge sets... the GO gauge is used to insure that the longest in-spec cartridge case will reliably chamber. Another way... If it won't go to battery on the GO gauge, there's at least a chance that you'll encounter a factory round of ammunition with a case length of .898 inch. While that will just chamber in the barrel when it's clean... it may present a problem when it's fouled.

Many bullseye smiths work to set their static headspace dimensions at the minimum... and some will go even as short as .895 inch for that class of precisely-built pistols. Bullseye competitors, as a rule, keep their guns meticulously clean... often field-stripping and cleaning between stages... so the tight headspace isn't really an issue for them.

Since I'm anal-retentive over reliability, and only give passing interest to tight groups at distances outside of normal "fighting" ranges... I tend to set mine up a little looser. I like to see a static dimension of about .903-.905 inch for the best compromise... but even .910 is acceptable. I made a sort of "field" gauge that I use when I'm lookin' to buy a factory pistol... new or used. It's got a .912 dimension that I consider as a maximum unless I go into the deal fully expecting and/or planning to rebarrel the gun.

If the gun just goes to battery with light pressure on the gauge, it's acceptable. If it won't go to battery... it's a bonus.

You'd be surprised at how many new guns fail with the gauge... and even more surprised at how many new ones will nearly go to battery on a standard NO-GO gauge. Some new guns will even readily accept the NO-GO gauge, indicating that they're beyond ordnance maximum acceptable limits. I *ahem* sometimes use it as a bargaining chip to get a few bucks knocked off the price... depending on my plans for the gun, or the intended use... or sometimes the attitude of the seller.