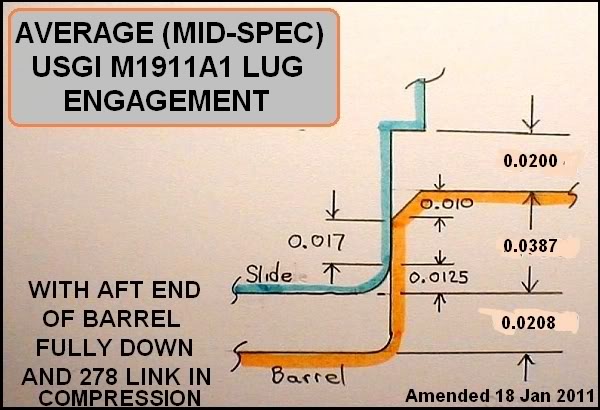

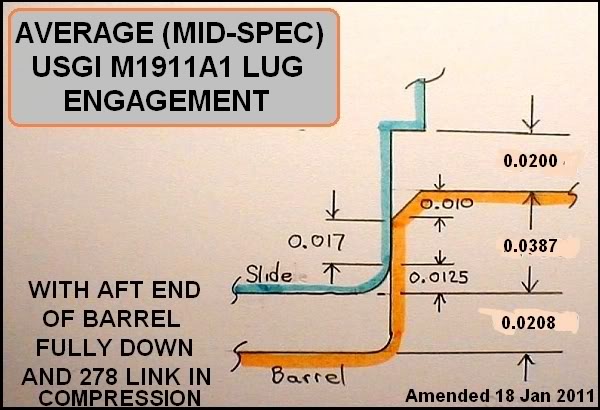

Earlier this year I had boldy posted a figure of 0.048 inch for the engagement of the first (aft) locking lugs in a mid-spec USGI 1911, choosing to neglect (for some stupid reason) any change caused the barrel's 52 second angle when in battery.

After re-doing all the calculations to include barrel tilt (slope?), I come up with a vertical engagement of only 0.038 inch.

This is only about 64% of the maximum possible engagement and seems much too little - to me, at least.

I realize many shoot for much more engagement when building a gun, but didn't expect it to be this low for a hypothetical gun where all the parts were in the centers of their tolerance bands (as shown in the Army blueprints in our Tech Issues section) with a standard 278 link installed.

Does this 0.038"/64% engagement seem way off to anybody?

As I understand it (but I am not a gunsmith) .060" is acceptable and .040" is not enough and needs attention. At .038" I believe that is too little lug engagement.

That was my understanding too, especially when the 0.038" was the mid-spec value where some could be more and some could be less.

Those with less engagement would be kind of scary unless they were corrected with longer links. But, I had the notion longer links became available only after WWII.

FWIW, the maximum possible engagement for this mid-spec gun is set by the depth of its mid-spec barrel lugs which is 0.0595 inch.

The result seems almost bizarre! Did the math twice with the same results. Hmmmmm...

Hint:

The height of the barrel lugs isn't the only factor involved. Take into account the height of the lugs in the slide... and whether or not they're bearing against the slots between barrel lugs. Take into account the slide's installed height on the frame. Take into account that these things sometimes change the barrel's tilt.

Understand also, that just because a locking lug shows 100% engagement, it may not guarantee that it's optimum. If the lugs are only .045 inch tall, and the slide lug is bottomed out in the slot, so that the forces are taken as low on the barrel lug as possible... you have a stronger lock than if a .060 tall lug is bottoming out in the slide, and mated to a slide lug that is only taking 75% of it.

Ideally, the barrel lug should bottom out in the slide's slot AND the slide's lug should bottom out in the barrel's... but that ideal is a little tedious to get most of the time... and you have to settle for one or the other. IMO... Better to have the slide's lug bottomed out in the barrel slot.

Measure the individual gun instead of relying on mid-specs... and keep in mind that the US Army didn't really consider the slides and frames as matched sets. All parts except the frame were considered expendable... service parts to be changed as necessary... and likely procured at least a dozen slides and barrels for every complete pistol that was delivered. Any sign of unusual wear or damage, and the part was replaced, with the bad stuff tossed into the scrap metal bin and returned to the foundries to be recycled for the war effort. Very often, slides and/or barrels were replaced as early as 5-6,000 rounds, regardless of condition. Kinda like spark plugs...

Quote:

The height of the barrel lugs isn't the only factor involved. Take into

account the height of the lugs in the slide...and whether or not they're

bearing against the slots between barrel lugs. Take into account the slide's

installed height on the frame. Take into account that these things sometimes

change the barrel's tilt.

All these were considered, as shown below (even if it may be hard to read at this size).

PICTURE 404

Quote:

Measure the individual gun instead of relying on mid-specs...

There's probably no individual USGI 1911 available anywhere (anymore) which is made up of parts with dimensions smack dab in the middle of their tolerance bands. All of this was done to see what the "average" 1911 would have for lug engagement, based on US Army blueprint dimensions.

Just seems like 0.038" is pretty skimpy engagement for lug #1 in a mid-spec gun. And, FWIW, the barrel's slope seems to be about 44 minutes of angle with a mid-spec USGI barrel bushing (whoopee-ding, huh?).

Do you know if longer (or shorter) links were available and used during WWII to obtain adequate engagement? Cheers

Quote:

Just seems like 0.038" is pretty skimpy engagement for lug #1 in a mid-spec

gun

It is... if you intend to shoot the gun 25,000 rounds a year. If you figure on replacing the top end every 6,000 rounds give or take... it'll do. I have seen very few that went less than 040 inch vertical... and I've checked a bunch of'em. Most seem to run in the neighborhood of .040-.042 inch, with several WW1 models checking as high as .048-.050 inch... but it's a moot point. The slides and barrels were soft. The engineers and the Ordnance people knew that the lugs would beat themselves into excessive headspace... and whenever that was gauged and deemed non-serviceable... they just replaced everything that was needed to correct it.

This is why we shoot the old service pistols very little, and only after verifying safe headspace... at least if we're smart.

Dunno about the long links... but I don't think so... at least not for inventoried service pistols prior to the early 50s. They weren't concerned with such things. The criteria was that the pistol be functional, and nothing else. The unit armorer's job was to make the pistol serviceable within the guidelines given to him. If the headspace checked out, he gave the pistol a pass. If not... he replaced the barrel and rechecked it. If it was still out... he replaced the slide and tested for function. He didn't waste time and effort on trivialities like vertical lug engagement in any individual weapon. Of course, whatever was replaced was gauged before installation... but that's about as far as it went.

Quote:

Most seem to run in the neighborhood of .040-.042 inch

Thanks for the info. It pretty well confirms the 0.038" based on 52' of barrel slope, because when re-calculated for a 44' slope, the engagement increases to about 0.040"!

As Gomer Pyle used to say - "Shazam!". Cheers

Quote:

when re-calculated for a 44' slope, the engagement increases to about

0.0

Yup... and if a particular pistol has a slide installed height at minimum spec... the engagement increases, too. A perfect example is a Norinco that I just got through cussin' and prayin' over.

I'll try to make it short.

The barrel lugs were being deformed badly, and a quick check indicated that the vertical engagement was only about .030 inch, give or take. The gun was looser than most Norks I've run into, but either hadn't seen a lot of use... or somebody had been replacing barrels about every 5-6 hundred rounds. The gun had some repeated failures to go to battery, so that was addressed during the rebuild.

The current owner didn't really want to throw a lot of money at the gun, since it was destined to be a range beater, and possibly an occasional carry gun... so We opted to stick with an unused Norinco take-off barrel that I'd had for a while... just in case anybody wanted it.

I beat the frame rails down more than I've ever done, and recut the rail way floor below the frame enough to start the slide... whittled and lapped until I got it slippin' like it should... and installed the barrel. The headspace was the best that I've ever seen on a stock Norinco with a stock barrel... so I knew ahead of time that I had some wiggle room on the horizontal lug engagement. The vertical ended up at .045 inch with the slide lugs bearing against the bottom of the barrel slots.

The problem was, that the #1 lug didn't hit... and because the barrels are hard-chromed and impossible to file... I decided to equalize the lugs with heavy, near proof-level ammo... and dress the flanging as the lugs seated. It took several restarts, but I finally got the first lug invovled, and the setback stopped.

Long story short... he reports that the gun is not only 100% reliable, but just today I learned that it consistently outshoots a Clackamas Kimber that's pretty good in the accuracy department. The gun retained the OEM barrel bushing and link.

This is the one that nearly whipped me. I was sweatin' bullets for a time.

Quote:

and because the barrels are hard-chromed and impossible to file.

Tuner, you need some Diamond files made by DMT or EZ Lap. They will cut anything.

Quote:

you need some Diamond files made by DMT or EZ Lap. They will cut

anything.

Yeah... but there's no use in investin' that kinda money when I usually just chunk the problem Norinco barrels and replace'em with a Kart. This one was a favor for a bud.

Thanks for the story about the Norinco. Have never even seen one. Are they about in the same league as a pre-Kahr Auto Ordnance?

Quote:

Are they about in the same league as a pre-Kahr Auto Ordnance?

Good God! Bite your tongue!

The Norincos were all steel with exactly ZERO MIM or investment cast parts. Good steel, and as tough as pig iron. With the exception of a few that were sloppily built, the biggest majority that I've examined and/or owned... and there have been many... they were built to spec, and boringly reliable. Accuracy wasn't exactly sterling in most of'em, but it was more than adequate for a rough and tumble service-grade pistol.

When they first hit the market, I was leery and missed my chance. If I had my time to do over, I'd have borrowed money and bought a pickup truck load of'em... for 249 bucks US out the door.

Ugly, and rough around the edges to be sure. Some rougher than others... but solid. As the mountain man said: "He'll do to ride the river with."

A diamond file costs about $8 bucks.

Quote:

a diamond file costs about $8 bucks

Square pillar file with 2 safe sides? Where do I sign up?

Like I said... I don't normally fiddle with a bad Norinco barrel. They're not worth the effort, and whenever I cut the lug faces on a steel barrel, I chuck it up in a lathe... paint the face of the lug with layout fluid... square the tool up against the lug... turn the chuck by hand and sneak up on a scraping cut with the compound rest set on 30 degrees, then clean up with a pillar file.

The lathe works right good to cut barrel hoods, too. Same deal...Turn the chuck by hand and sneak up on it.

Quote:

Square pillar file with 2 safe sides? Where do I sign up?

Check here and see if there might be something you can use.

http://www.dmtsharp.com/products/diafold.htm

My wood working hone has abrasive to the edge and no grit on the sides. Surf around and see if other configurations may be better. I use the extra coarse to flatten my Arkansas oil stones. Joe

Engagement Picture

After some more noodling around with numbers to recheck the 0.040 inch vertical engagement distance, decided to churn up a pic of the lugs and include the mid-spec values of the corner chamfers and radius.

With the gun just assembled before any firing and the aft end of the barrel fully down, the vertical extent of the lug contact area (maximum at the gun's centerline) works out to a tad less than 0.018 inch.

Now that's what I call scary!

I couldn't survive without my diamond hones.

I like the Eze-Lap brand.

Quote:

Now that's what I call scary!

Makes ya wanna take your stock pistol and do a .45 Super conversion... don't it?

Why do you show the slide lugs with that heavy radius? The barrel lugs usually don't require a chamfer unless there's an early engagement issue... which is why I leave a .003 inch clearance between the breechface and the barrel hood. It really isn't necesary to fit one that tight except on a Bullseye gun, and most of those shooters go with "Softball" ammo, making the lugs' contact area less critical.

Quote:

I couldn't survive without my diamond hones

I like the eze-lap brand

I'll give'em a look, Blade. Guess I've been old-school for so long, it's hard to change.

Geezer... is probably the right word.

Quote:

Why do you show the slide lugs with that heavy radius?

I showed it only because the most recent (ca 1961) US Army blueprint by Rock Island Arsenal specifies "Break sharp edges of locking cuts and barrel clearance cut .010R + .005 or .010 + .005 X 45 degrees all around". The mid- spec value is 0.0125 inch.

A much older blueprint by Springfield Armory (ca 1928) doesn't seem to specify any adge breaking - at least I can't find it anywhere on the not-too- clear scan available.

Quote:

The barrel lugs usually don't require a chamfer unless there's an early

engagement issue...

Again, the mot recent RIA blueprint specifies a ".005 + .010 X 45 degree" chamfer and 0.010 inch is the mid-spec value of that one.

Oddly, the older SA blueprint says "Remove corners not more than .005 X 45 degrees" (emphasis mine).

Not having a complete set of the older SA blueprints I pretty much have to rely on the more recent RIA, etc, ones from CNC Gunsmithing. Besides, the scans of the old SA prints (available at TheSight) are impossible to read in many areas.

But, thanks for jarring me into looking at the older prints. The picture for the lug engagement in a pre-WWII gun would be much different and better looking. (Hubba-hubba ) Cheers