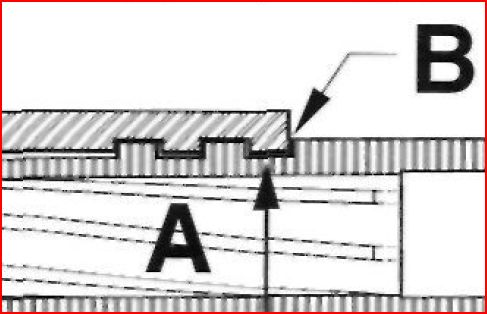

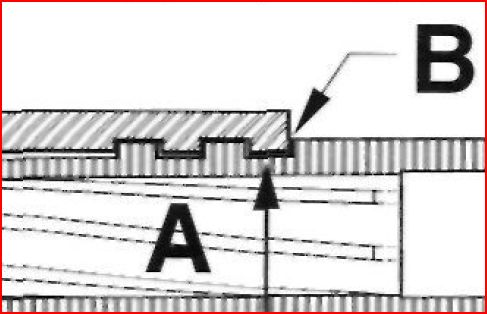

Should the lugs must fit on the 1911 as shown above in battery? Or there are clearances between the slide lugs of barrel and slides?

I am asking this question because when I am putting my barrel inside the slide with the bushing attached, I can move the barrel up the lugs so it means there are spaces between the lugs of the slide and barrel, another, can someone explain springing as I guess I am experiencing this as I exert a certain amount of effort to move the barrel up the slide locks.

Btw, figure was taken from Kuhhensen book volume II.

Well, I am not sure I understand the first part of your question, but that's not something strange, at this time of my day (my braincells are usually half- asleep until about 10:00 am) but springing is a condition where the bushing is not allowing the barrel lugs to go as far up as possible. You can easily see it, with the slide revered (up-side down) the bushing and the barrel in the slide, if you press on the rear of the barrel and it goes down but pops up again when you let go, you've got springing. The bushing needs to be machined properly to avoid this.

I'll restate my question, if the slide and barrel is into battery position, somewhat like locked and loaded, must the lugs fit as illustrated? or there is a space/clearance between the lugs?

Contact points were pointed by the arrows.

Follow up question, when measuring the upper lug engagement, that is the one you measure the top of the barrel to the top of the slide, is it needed to have the barrel bushing installed or not?

The fit as shown in the illustration you posted is the way they fit at the start of recoil, when the slide is pulling the barrel back. In battery, the forward edges of the slide lugs will be pushing the barrel forward. There is a small gap, as shown.

I noticed this on the 1911, when the barrel is on battery or loaded, it is not really parallel with the frame nor the slide, it is quite tilting downwards, is this normal?

Quote:

Follow up question, when measuring the upper lug engagement, that is the

one you measure the top of the barrel to the top of the slide, is it needed to

have the barrel bushing installed or not?

Yes, it is necessary to obtain an accurate measurement.

Quote:

I'll restate my question, if the slide and barrel is into battery position,

somewhat like locked and loaded, must the lugs fit as illustrated? or there is

a space/clearance between the lugs?

Point "B" should be in contact when in battery and will be if the hood length is cut correctly.

Point "A" will be in contact if the barrel is a hard fit barrel and is advantages to accuracy.

Quote:

I noticed this on the 1911, when the barrel is on battery or loaded, it is

not really parallel with the frame nor the slide, it is quite tilting

downwards, is this normal?

Yes, this is not only normal, it is by design.

Is it also normal that the barrel is quite pivoting on the rear barrel lugs in the slide?

Because I am taking measurements, have a drop in barrel, the barrel hood fits nicely in the slide without any modifications, it is a drop in but a match barrel, and noticed that when I push the lower lugs up, I feel a small resistance, and as described it is springing, should I correct it or just leave it alone?

Springing should be corrected.

If you are experiencing "springing" the problem lies with the bushing. There should be a couple of clearance bevels inside the bushing allowing the rear of the barrel to pivot downward without the bushing trying to push the rear of the barrel back up into battery. If you have the Keunhaeusen books, look up fitting of the bushing. IIRC (I don't have my copies with me) the section of Keunhaeusen's books covering fitting of the bushing also describe the clearance bevels.

Quote:

The fit as shown in the illustration you posted is the way they fit at the

start of recoil, when the slide is pulling the barrel back. In battery, the

forward edges of the slide lugs will be pushing the barrel forward. There is a

small gap, as shown.

The illustration shows the forward barrel lug face bearing against the rearward slide lug faces and this is the position that should be maintained if the hood length is cut correctly. The forward slide lug faces should not contact the barrel rearward lug faces except at the hood as it is being contacted by the breech face. The difference between the slide lug recesses and the barrel lugs #2 and #3 is well over .020".

Quote:

I feel a small resistance, and as described it is springing, should I

correct it or just leave it alone?

With barrel and bushing in slide, you should be able to push the barrel in to full engagement and it should not push back(springing) and it should be able to drop out of engagement under the barrels own weight. If it is springing, the bushing needs to be relieved at the front lower and rear upward areas of contact until it no longer springs. If, once the barrel is pushed up into full engagement and it doesn't drop down under it's own weight, then the hood needs additional fitting.

I'm sorry the first question doesn't make any sense to me if the bushing is in place and if it isn't, that doesn't make any sense.

Quote:

...if the slide and barrel is into battery position, somewhat like locked

and loaded, must the lugs fit as illustrated?

No, it is not absolutely necessary that the radial locking lugs fit as illustrated.

A little background info may be helpful.

This drawing shows the horizontal gaps between the lugs of a mid-spec USGI (not National Match) M1911A1 when in battery:

PICTURE 404

This drawing shows the vertical gaps and engagement (overlap) for the #1 lugs of the same gun just after firing - when the barrel has moved forward in the slide:

When the term "engagement" is used, the chamfer and radius are not considered, so a mid-spec USGI M1911A1 will have about 0.040 inch of vertical locking lug engagement at the #1 lugs. The vertical engagement of the #2 and #3 lugs will about 0.005 and 0.010 inch less, respectively.

However, barrels can be fitted for more vertical engagement - just to provide more bearing surface and give the lugs a longer life. Barrels can also be fitted for the maximum possible vertical engagement - to provide the utmost in accuracy potential.

Maximum possible vertical engagement and accuracy potential is possible only when the slide stop pin forces the barrel up into the slide and also forces the barrel to force the slide up as far as it can go on the frame. The amount of maximum possible vertical engagement for a mid-spec USGI (not National Match) M1911A1 is 0.595 inch - the height of the barrel's #1 lug.

When this is achieved, the gun's lockup is said to be "tight". When in battery, there will be no discernable vertical play between the frame, barrel or slide. One way to tell how tight a 1911's lockup is involves putting a wood or brass rod down the barrel and forcing the aft end of barrel up & down. If it's really tight, it won't move at all!

This kind of "tight" lockup is impossible with gun that rides the link all the way into battery because the link allows the barrel to drop about 0.003" after the link passes vertical on the way to battery.

I'd strongly advise a thorough study of your Kunhausen books before proceeding further. I've heard all you need to know about fitting your barrel is contained in them.

Lug cutter choice - Which one?

Is it a must to buy the 0.186" Cutter or should I jsut buy the 0.195" Cutter, only?