How are you guys measuring the slides barrel hood length? I know about the neat little EGW tool (I need to order one).

I have an old barrel I milled the hood back about .030" (measures 1.292"), I slip this in the slide, then use feeler gauges until I have a good tight reading. I then add this into my gauge barrel, in one case 1.292" + .030" = 1.322".

So what's your method?

I've done it your way. I also have the EGW tool. Either way only get you the first lug measurement. I fabricated a variation of the EGW gage from some aluminum flat stock in order to measure the other lug spacings. You could modify a couple more junk barrels to measure the other lug spacing. I've since bought a digital height gage and surface plate. Why worry about the other lugs? I'm just that way. I don't think that it's very important on 45s or 9s. I do think that it is critical for bulleye guns and important for hot calibers like 10mm, especially in shorter that 5" to ensure longevity.

Quote:

How are you guys measuring the slides barrel hood length? I know about the

neat little EGW tool (I need to order one).

I have an old barrel I milled the hood back about .030" (measures 1.292"), I slip this in the slide, then use feeler gauges until I have a good tight reading. I then add this into my gauge barrel, in one case 1.292" + .030" = 1.322".

So what's your method?

Suggestion;

If you are going for as much precision as possible, forget feeler gages,

spacers, etc. You have to be able to measure in the tenths to get a precise

fit, or all three lugs touching. Even a surface plate can be tricky when

trying to get the slide lugs. A good centering scope in the mill will get you

repeatable readings to within .0005 on your DRO. My lathe DRO will get me to

.0002 It's very difficult, almost impossible, to get good contact on all three

with hand tools. I have pictures of the set ups somewhere if you need them.

I'll bet there's more than one or two of us that would like to see that. can you tell me what you use to true the slide bore? A reamer, hone, lap?

If needed, an adjustable brass lap that has been trued between centers.

Not all slides need truing. The old Colts are usually out of round.

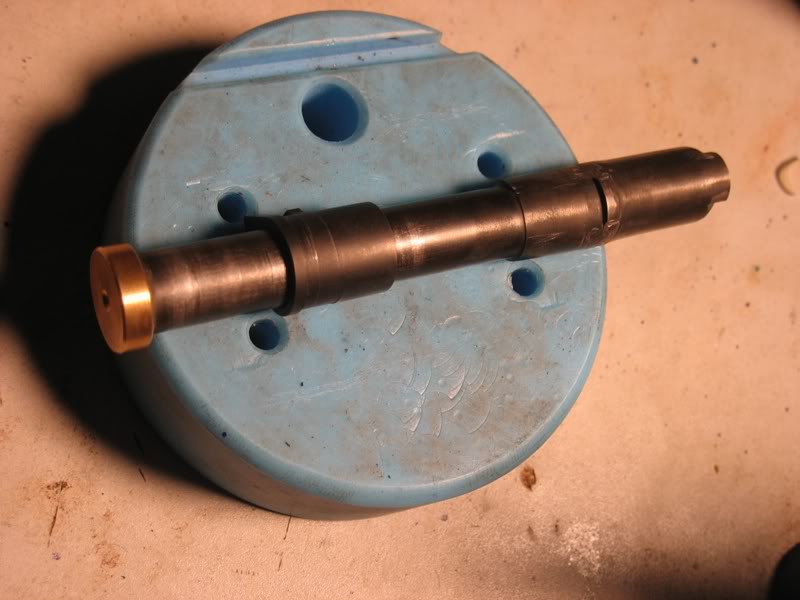

I pulled off a three lug contact with a tight fit hood using an old barrel modified to locate my slide lug locations;

Modified a barrel by removing all but the No.1 lug

Installed a bushing and plug to locate a datum on the end of the barrel

Measured the slide lugs to .0002 with a drop indicator calibrated to ± .0001 like this:

Adjusted the barrel so that all three lugs contacts simultaneously with a 1911 Brownell's hammer hook file:

1911-AUTO-HAMMER-SQUARING-FILE

Welded up the barrel hood and recut to the slide length I measured with a EGW hood length gauge

I ended up with full three lug contact and zero end play...

This is how an old FL cracker does it in his garage without spending big $ on height gauges...

I hold the slide in a vertical V-block and measure with a B&S micro-hite.

Quote:

How did you match the lug radii?

I didn't need to match the radii because I left the barrel number one lug radii as is on my tool.

I don't own a height gauge which is what most people use to measure both barrel and slide lug spacing so I made a fixture from an old barrel. I completely removed the number 2 and 3 lugs from the barrel. Then I used my belt sander to remove material from the hood to lower the hood surface level with the bottom of the number 1 lug while leaving about .090 to simulate a lug... this allowed the barrel to ratchet from lug to lug in the slide.

Then I made an end cap with a drill point at the muzzle to hold an indicator tip. I held the slide on my surface plate with a toolmaker's vice and measured the slide lug axial locations with a .0001 drop indicator.

Next I transfered the slide measurements to the barrel and removed a little material from lug 1 and 2 to allow lug 3 to contact... this was nerve racking but I pulled it off.

Lastly, I used an EGW hood length gauge to measure what my hood length needed to be... I had to weld the end of the barrel hood to match the distance.

Lug 2 bottoms in the slide with 100% no 1 lug engagement... I think that's because its a Bar-Sto barrel. I didn't have to change the barrel radii.

Got lucky with this one