Seems I need a new barrel for my 1991A1. Bad rifling.

I don't have the money for a Kart or the likes and to have it fitted.

So my question is;

If I get a barrel that has already been fitted in a Pistol, will I have to have it fitted to my pistol.

I took the barrel out of my Springer Mil-Spec just to see how it fit and it fit and functions fine. It's back in the Springer.

So I found a couple of new take off barrels from 80 Series Colts and I found a lightly used Springer barrel. Would one of these be OK?

What should I be checking for?

I'm facing a barrel fitting task soon and have been reading everything I can find on the subject. I'm putting a 40S&W barrel into my 10mm Gold Cup for economic reasons.

Anyway, it would seem to me that in your instance the only thing you should have to worry about in just randomly inserting different barrels is the possibility of tolerance stacking. Presuming that every gun gets at least a cursory fitting, you could possibly end up with two pieces that would work fine in their original homes but due to tolerances may be at the extreme end either way and when coupled together be unacceptable. So just because a barrel installs and locks up OK doesn't necessarily mean it's right. Barrel hood length comes immediately to mind. It's a fairly outside chance, but possible.

Quote:

What should I be checking for?

If all three barrels have good looking bores & chambers, the only meaningful check is to see if the barrel fits into your gun.

If any of the barrels you're considering still have a link installed, just be aware it may not be the right link for that barrel when it's in your gun.

All 3 barrels have the link installed.

Any easy way I would be able to tell if its the right link?

Quote:

Any easy way I would be able to tell if its the right link?

There's no "easy" way unless you're quite familiar with what the link does in a 1911. But, for starters...

...perform the timing tests from Schuemann barrels found in our Tech Issues section, but don't concern yourself with the amount of clearance between the slide and the top of the barrel - just make sure the barrel gets down far enough the clear the slide by any amount. And pay no attention to those steps which tell you to either lower the barrel bed or move the VIS back.

As a start, you might want to use the link that was on the original barrel in your gun. If that link was OK with the original barrel and the new barrel's not too much different, it might all be OK without any fiddling. Maybe.

Well I got me a brand new take off barrel/link & bushing today

Link is the same size as the one on my original barrel.

Barrel to bushing fit is alittle tighter than my original

I will take it to my Smith to have it checked over, make sure it is fitted proper, have the slide to Frame fit tightened up a tad and a Throat Job done

Quote:

I will take it to my smith to have it checked over, make sure it is fitted

properly, have the slide to frame fit tightened up a tad and a throat job

done

Why?

If this is a Colt barrel, it's already "throated." Remember... If it ain't broke, don't fix it. 1911 barrels these days are made to feed both ball and hollow point ammo. Unless you plan to shoot a lot of wadcutter and you have already proven that it won't feed... do not muck around trying to throat a barrel that probably doesn't need it.

Quote:

Why? If this is a Colt barrel, it's already "throated." Remember... If it

ain't broke, don't fix it.

+1 for what Hawkmoon just said!

Don't forget that various members of this forum have probably fitted several hundred 1911 barrels between them and the right kind of picture will tell them whether or not anything needs to be done to your barrel.

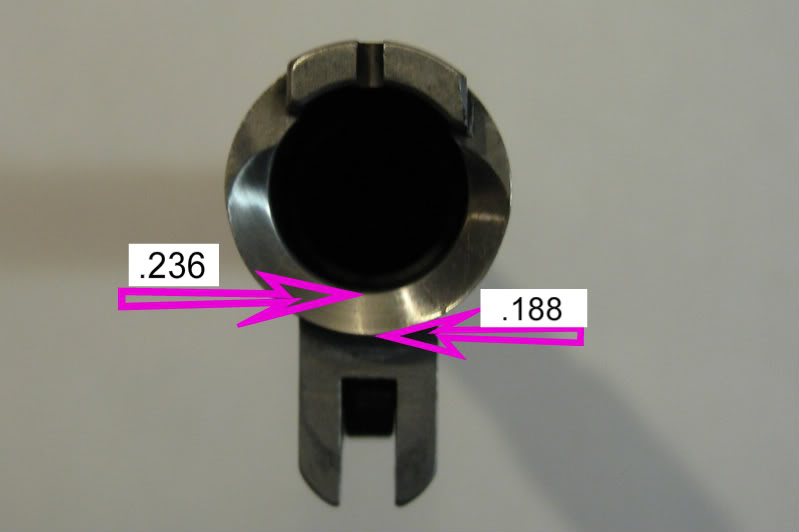

The kind of pic they'd need is like this:

but with the frame & barrel cleaned and the barrel linked to the frame and held fully down and aft in the frame.

Please let them have a look-see before having anything done to your gun.

I won't have any work done yet, except check for proper fit and function.

I will be shooting mostly 200gr. Semi-Wadcutters and this will also be a CCW pistol, So it will also need to feed 200 and 230gr. XTP's reliably.

I said throated because I have not seen one with this cut before.

All input is appreciated

Looks like a wadcutter throat with the left side a bit over done, but that's no real big deal.

However, it does appear as if the junction between the barrel ramp and the chamber is rounded over way too much. But, it may be just the lighting or my eyes. The current spec for that radius is 0.03".

It does appear rounded alot, but then again I don't know what it is supposed to look like.

Here are a couple more shots:

It's kind of hard to tell at that angle and reflection but the overall throating doesn't look to be as deep as usual. The secondary cut in the middle may very well be sufficient to give proper case support. That's the main reason for only breaking the edge .003 radius, as I see it. Looks like it might actually work. There's more than one way to skin the proverbial rabbit. Then again it might be why it's a takeoff. The OP didn't mention what brand of gun it came off of. Maybe that's how they do them on some brands or maybe somebody has massaged it a little bit. Only one way to tell if it works or not.

Another thing that caught my eye was the hood chamfered on the inside. Is that SOP on .45 barrels? My 10mm barrel isn't chamfered at all on the hood.

The barrel is brand new, unaltered 80 series Colt, all parts were removed from pistol for a Custom build.

Yes the chamfer at the top of the chamber is normal for a .45,

Judging from your latest pix, it looks the central portion of the ramp is cut too far forward into the chamber. Here's a drawing of the ramp profile based on the latest U.S. Army specs:

The junctions between the chamber, chamber face and ramp are broken with a radius of 0.03" (3/100").

Cutting the ramp too far forward into the chamber increases the amount of case not supported by the chamber. G. Kuhnhausen sets a limit of 0.090" of brass exposed between the case bevel and top corner of barrel ramp.

This barrel looks like it may exceed that limit, but measuring it is not real easy. There's a thread titled "Unsupported Measuring..." on this forum with more details. Search it out.

Well, if it's an unaltered Colt barrel, maybe my eyes were playing tricks on me.

Hi, Niemi here is a picture of that same barrel in the frame and if anything it looks like it has plenty of support. The proof would be to know the actual dimension from breech face to break over corner with the barrel as far forward in the slide as possible. This max. dimension is .250"-.260".

The method shown in Post #10 of his thread http://forum.m1911.org/showthread.php?t=28011&highlight=unsupported+measuring is kind of tedious to perform, but it doesn't require the use of the chamber go-gauge like in Kuhnhausen's Vol. 1, pages 68 & 69.

But what the heck - if it's an untinkered Colt barrel, it's just gotta be OK, doesn't it? Shouldn't it? Wouldn't it?

Quote:

The proof would be to know the actual dimension from breech face to break

over corner with the barrel as far forward in the slide as possible. This max.

dimension is .250"-.260".

Not to sound to stupid, but how do I do this ?

Oh, oh, LOL I was hoping you wouldn't ask. Okay here's one way that makes sense to me. First I determine how much clearance there is between the hood and breech face when the gun is fired and the barrel and slide are pulling in opposite directions.To do this I close the slide into battery with progressive feeler gauges in between the hood and breech face until it won't close and so let's say we determine that is .005". So this means that if we take the .250"- .260" and find that from the end of the hood squared down to the ramp the acceptable dimension would be .245"-.255" considering the .005" of hood to breech face clearance.

To begin with I will set these squares with .245" of overlap,

Then align it with the ramp corner,

And then take a look to see if it's more or less,

I measured my Colt and my Springer.

Colt first:

Springer Mil-Spec.

This Pistol feed 100% with 200gr. SWC and 230gr. JHP

Quote:

What do you think of my last Pics with Measurements?

Nice pix, but do the numbers in them include the distance from the hood to the breech face with the barrel in battery & fully forward in the slide?

Either way, it looks like your new barrel will adequately support the case as the hood to breechface gap is usually less than 0.010".

For me, the "iffiest" part of measuring this is determining exactly where the chamber/ramp radius begins in the chamber. That's why I came up with the "scraping off the sight black" method in that old thread.

Well, it appears you have answered the important question and we await your firing of the gun with this barrel. Have you tried fast hand cycling the gun yet? I use a cut off firing pin, or dummy rounds. Be careful, and let us know how it goes, so far, so good.

The Colt has .005" hood to the breech face and was included in the measurement. The Springer has .000

Yes; I have tried fast Hand cycling with a full 8 round CMC Power Mag and it cycles great.

Hopefully I can give a range report tomorrow.

Interesting thread! Hylander, you're in good hands here with Niemi and Log man.

Before taking that first shot, just insure the locking lugs get vertically disengaged before the lower lugs hit the VIS (link in tension) and that first frame contact when linking down is made at the VIS - not the barrel bed.

But, you've probably already checked that, huh?

Not sure, How do I check that ?

Quick check, with gun fully assembled and slide stop pin in frame, but arm hanging down in trigger guard area push the muzzle against a surface and while pushing firmly the slide stop should be free to move. If so your good. this proves the barrels rearward movement is stopped by the VIS(vertical impact surface) in the frame and not being stopped by the link.

Also in this position you should have at least .010" of clearance between the barrel top and inside of slide.

Thanks Log Man:

Did the check and yep the Slide stop pin is free to move, Also I have the

Hood clearance

Log Man's quick check is OK. There's a more detailed description of barrel timing in our Tech Issues section from Schuemann Barrels, http://www.m1911.org/testkit.htm .

Went for a test drive this morning. She ran like a Timex. Just shot for function, I will go back tomorrow and put it on paper.

All I had for ammo was 200 SWC on top of Unique.

I tried a #12, #16 and #18 recoil springs, all functioned 100%, but the #16 felt the best.

Leading was almost zero, couple of swipes with a brush & patch and the Bore looks new again.

Boy is that Unique dirty