After edumacating myself big time by reading many excellent posts here, I have come to understand that the barrel throat is merely a hurdle for the bullet to clear, based on it bouncing off the frame ramp, especially as the unsupported rounds in the magazine nose dive.

But, is it true that the barrel throat angle is optimal at 45 degrees? I read conflicting things on this, and I see that while some high quality 1911's do indeed have nicely throated and polished barrels, the angles are often noticeably more obtuse than 45deg.

Also, what's the deal with Colt's approach to the barrel throat (the right most barrel)?

Also I know that it is hard to guess reliability from slowly controlling the chambering process by riding the slide and chambering the round very slowly, but with hollowpoints, the bullet definitely stops and hangs up against the barrel throat. Now this same bullet will chamber successfully during normal cycling (I guess do to the bullet bouncing off the frame ramp and clearing the throat), but it is hard not to be convinced, and I know, probably erroneously, that a channel cut into the throat, or a more acutely cut throat angle, at the risk of causing lack of chamber support, wouldn't make for a more reliable pistol, especially with hollowpoints.

I mean when I control the slide on my USP and Glock and slooowly chamber the round, the round hits the top of the ramp and just slips in the chamber.

Also, arguing against the "round bounce off the frame ramp" necessity of the 1911 design, is the fact that with the last round in the mag, using a Wilson mag at least, the bullet has an almost straight shot into the chamber. Therefore, why not channel the barrel throat so that rounds don't have any chance of hitting the barrel throat and slip in there with ease?

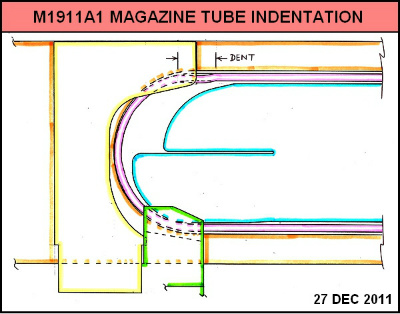

First, I understand what you are referring too, but the throat is the area between the chamber shoulder and rifling. The area you are talking about is the barrel ramp. I know that in several publications the barrel ramp is referred to that way when it is extended up the sides as is commonly done today. The barrel ramp angle is specified at between 30-35 degrees, and the frame ramp is 31.5 degrees. Colts "dimple" in the barrel ramp gives break over clearance without exposing too much unsupported case.

The 1911 is a very successful 100 year old design and remains that way as it is a 1911. Something to remember is the design differences in most newer designs is the barrel tilt, in the 1911 it is level when loading and the chamber is pushup at battery. The design you are referring to is level in battery and the chamber drops down to an easier angle to load. None the less the 1911 can be 100% reliable with proper tuning.

Yep I realize that the modified Browning tilt barrel design enables a straighter feed trajectory (for the lack of a better way of putting it)...

Quote:

First, I understand what you are referring too, but the throat is the area

between the chamber shoulder and rifling. The area you are talking about is

the barrel ramp.

Thanks for the terminology clarification. But when I think "ramp" I think of a ramped barrel, like some of the Para's use. Here they are calling it a "barrel hood"(?), and 45 degrees is described as optimal? 35 degrees is pretty flat/acute! My CQB's barrel ramp/throat is definitely not 35 deg... it isn't even 45 I don't think!

Yes, and the point was that the Glock and others design allows for chambering in the barrel chamber tilted down position, an easier position to load from the mag as the round slides up into the chamber and doesn't have to break over as much.

I understand, but a barrel ramp and a ramped barrel are two different things.

The spec, for the barrel ramp is 30-35 Degrees and that IS less than 45 degrees as the angle is read from vertical being 0 degrees. The 45 degree bevel mentioned in regards to the hood is in regards to the chamber side of the hood extension. Nothing to do with the barrel ramp.

The magazine has something to do with the angle of feeding as well.

I run Wilson 47D's, and the bullet never touches the frame ramp... it'll hit the throat straight on every time.

Quote:

I run Wilson 47D's, and the bullet never touches the frame ramp

I have several of the 47D's and the bullets definitely hit the frame ramp!

Didn't think it was possible to by-pass the frame ramp in a 1911.

I've found that where the bullet makes first contact on the frame or barrel ramp depends very much on how many cartridges are in the magazine.

The first round fed from a full magazine will hit low on the frame ramp. This is because it nosedives and little can be done to prevent it from doing so:

It all has to do with the angle of the magazine.

The last round fed from the magazine will hit the top half of the barrel ramp. This is because the follower provides good support for the front of the last cartridge to largely prevent nosediving. Follower support for the cartridge column begins to fizzle out after the 4th is loaded.

And, the ones in between will hit somewhere at or in between those points.

At least that's how my Petunia works with the mags I have for her.

Quote:

Didn't think it was possible to by-pass the frame ramp in a 1911.

Sure it is.

If anybody wants to test their gun(s) to see where the bullet hits, I've found the best thing to mark the barrel and frame ramps with is sight blackening compound.

It's nothing more than lamp black suspended in a light alcohol (for quick evaporation). The soot layer left behind is very dull and very easily removed by the bullet - much more so than using layout fluid or a magic marker.

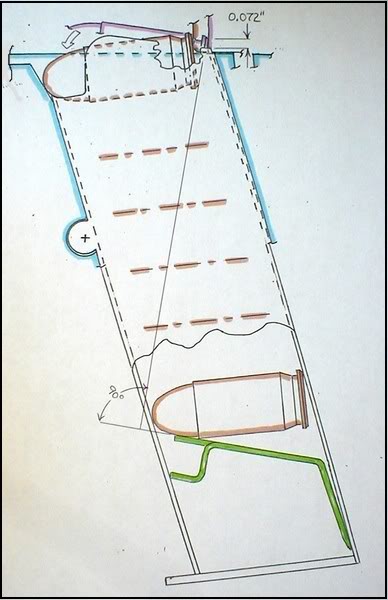

That drawing scan I put in Post #8 was pretty sorry-looking, so here's a better one showing what I believe to be the ranges of contact for cartridges being fed and chambered:

PICTURE 404

* The cartridge in the middle is aft in the magazine waiting for the slide to strip and feed it.

* The lower one's the top round in a full magazine and is nosediving, about to hit low on the frame ramp - where it glances up and makes contact only with the top corner of the barrel ramp.

* The upper one's the last round in the magazine (with good follower support at its front) and doesn't come close to hitting the frame ramp. It hits in the top half of the barrel ramp.

At least that's how I have it figured out. Your results may (and probably will) vary.

Very informative picture, and yes based on the fact that beyond round 5, the rounds don't have relative support from the round beneath, then this makes sense, and it is what I've always understood to be the case. It is almost impossible not to have the 1st three rounds or so (in an 8 round mag) nose dive and hit the frame ramp.

You guys might have seen this already, but here are the video links from Tripp research on.

LINK 404

So now I see why some argue for the use of 7 round mags, and a follower design that keeps the rounds oriented nose high, as they give better round support and prevent nose dives.

One cannot argue however that the last round in the mag, especially out something like a Tripp or Wilson mag, has the greatest potential for good feeding, as it almost has a straight shot into the chamber. The only thing that could confound the situation, I guess, is if the mag releases the round too early, or doesn't control it enough, so that you get a push feed.

But, if the optimum is indeed what happens with the last round and its "straight shot" into the chamber (more or less and understanding that the round still hits the shoulder of the barrel ramp), shouldn't that barrel ramp be more channeled so that even the rounds that tend to nose dive have an easier time getting into the chamber?

Also, this is blasphemy to many I'm sure, but how can one argue that the 2011 design with the inherently superior double stack mag design (except in the realm of girth) and fully ramped, integral, barrel is not the direction to go in 1911 design.

In other words, slightly stagger the mag, use thinner grips to keep the girth down, and maybe use a ramped barrel; although if the rounds are presented and supported better and they feed like the last round in a standard 1911, where they just hit the shoulder of the barrel ramp, a full integral ramped barrel won't even be needed.

What do you guys think? Or should I just keep my day job?

Nice drawing Niemi24s,

So, the the last round does not hit the frame feed ramp?

If so, that's the only cartridge that does not?

As I've "read" here, the 1911 is a controlled feed design and the cartridge is supposed to be hitting the feed-ramp and breechface, extractor also of course.

DacoRoman,

The fully ramped barrel is definitely not the way to go in a 45 anyway. I doubt you'll find any 1911 smith recommend a ramped barrel because of reliabilitity issues.

I'm not aware of the how the doublestack magazines present the catridges, as opposed to the single stack. But, if it shows better on Tripp's site, then I'd have to say that's where reality differs from theory. Doublestack 1911's are widely known to be less reliable than singlestacks.

No doubt there are reliable doublestacks running, but any of the organizations, smiths etcs that make and "run" 1911's hard, use the single stack.

The FBI once had doublestack Para's... dumped those and went to singlestacks. On a another forum, they "showed" some of the doublestacks that were tested by "some" armed forces and had "mixed" results... nice way of saying they didn't work well enough.

So, don't know! The doublestack, plastic framed 1911 should have been a winner with people that "really use them"... extra capacity, lighter weight, etc... but... they don't!

Just remember-the more throating you do to the barrel--the more support you're taking away from the cartridge case...

Quote:

Just remember-the more throating you do to the barrel--the more support

you're taking away from the cartridge case.

While increasing the barrel ramp is called throating by some it is confusing as the area between the chamber shoulder and where the rifling begins is the throat. A throating reamer for example is designed to cut this area, not the barrel ramp. I know J.K. refers to it that way, but it is a misnomer. Increasing the barrel ramp will expose more of the case and it will be unsupported, which the .45ACP was designed to tolerate, as it is unsupported up to .260" from the case head/breech face.

FWIW, I have seen that vertical surface at the aft end of the chamber into which the ramp is cut and from which the hood projects referred to as the "chamber face". Don't recall where I'd seen it, though.

Throating is really the widening & contouring of the barrel ramp, to allow the greater accessibility of the round into the chamber.

The other part of the process, is to make sure the point at which the barrel ramp becomes the chamber, is not sharp. But a smooth transition point from the ramp to the chamber.

And yes, it is possible that the round never touches the frame ramp.

Some do, and of those that do, usually touch at the upper 1/4-1/3 of the frame ramp. So most polishing of the frame ramp I see is really over done, and over rated.

Interesting. I don't dispute what you are saying about Para's double stacks, however I thought that the STI and Infiniti double stack designs are pretty darn reliable

Quote:

You guys might have seen this already, but here are the video links from

Tripp research on.

LINK 404

The link seems to be correct, but the videos don't play for me. All I get is a black rectangle that flashes a few times, then nothing happens.

Weren't me that posted that, Daco. But I tend to agree. MY STI is pretty particular when it comes to feedable bullets. I just give it roundnose and quit agonizing.

The double column, center feed magazine inherited from the BHP is an adaptation to fit the most ammo into a pistol butt.

Quote:

One cannot argue however that the last round in the mag, especially out

something like a Tripp or Wilson mag, has the greatest potential for good

feedign, as it almost has a straight shot into the chamber. The only thing

that could confound the situation, I guess, is if the mag releases the round

too early, or doesn't control it enough, so that you get a push feed.

I would argue that premise.

The last round, IMHO, has the most likelihood of nosediving, because the last round has the least spring pressure holding it (and the follower) up. With the metal 8-round followers, it isn't the top rounds that nose dive, it's the last round. It nose dives because the spring can't hold up the front of the follower, and the short rear leg doesn't provide much resistance to tipping/tilting.

I don't accept the notion that the first round in a full magazine is most likely to nose dive. How can it? The spring is fully compressed, so it is apply the most upward pressure it possible can at any point for that particular magazine. Beneath the first round, there is a follower and six (or seven) other rounds that are all held in the magazine at the same slant/angle as the top round. The only way the top round can nose dive is if it can push down all six (or seven) of the rounds beneath it AND the follower -- which may be resting on a spring that is very nearly at the point of spring bound, which will not allow it to drop any more.

Quote:

The last round, IMHO, has the most likelihood of nosediving, because the

last round has the least spring pressure holding it (and the follower) up.

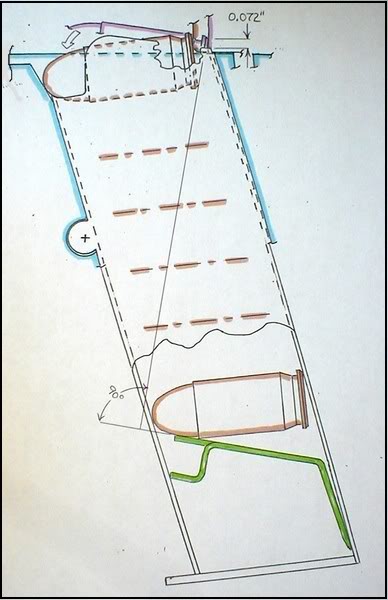

That's what I thought too, until I tested a few of my mags with 1 and 7 rounds in them to see where they'd make first contact with frame/barrel ramp. Using sight black on the ramps to detect the contact points I discovered [much to my amazement]:

* 1 round in mag hit in the top half of the barrel ramp, with no contact whatsoever with the frame ramp and

* top round in full 7 round mag hit about 1/4" down from the top of the frame ramp!

With all that extra pressure from the more-compressed spring, how could this possibly be, I wondered. Spent a few days investigating and finally discovered how. Even though there's more pressure from the spring, that force is transmitted upward through the follower, through the cartridge column up to the top round - but (here's the kicker!) to the aft end of that top cartridge!

This realization came after using a mockup of the magazine made from a machinist's protractor head & rule set at the follower angle with 7 cartridges on it, as shown here: http://i129.photobucket.com/albums/...P088270014d.jpg While there's indeed more spring pressure involved, that spring pressure is directed up through the front of the bottom round but not along the fronts of the rounds above it. The pressure moves steadily aft through the other rounds until it's at the very aft of the top round leaving it's nose essentially unsupported - and most prone to nosedive.

On the other hand, even though there's less spring pressure with just one round in the magazine, the spring exerts that pressure on mostly the front part of the follower (because of the upward kink in the top coil) and the front of the follower is directly under the front of that single round.

In short:

* 1 round in mag nosedives the least cuz it's got the most follower support under its nose, and

* top round in full mag nosedives the most cuz it's got the least follower support.

Had I not performed the feeding tests to see where they really hit and made the magazine mockup to see what the heck was going on down inside the magazine I'd no doubt still think more spring pressure has just GOT to mean less nosediving. It just sounded too logical not to be true.

Recommend you set your protractor head to 68.5° and give it a whirl!

Nice test.

It would be interesting to see how 2 rounds, then 3 rounds, 4,5,6,7,8 in a mag, etc react, i.e. where they hit.

Easy for me to say, or ask.

Try using a follower that doesn't pitch forward, or has very little movement such as a Wilson or the like. The longer skirt around the follower will keep that to a minimum... and also keeps the rounds straighter or a bit upward and not angled downward like what shows in the photo.

My experience, especially with 8 round mags, reflects what niemi is saying.

From an old thread:

Below is the reason why the top most round, beyond 5 loaded in the mag, has an increasing lack of anterior support from the rounds below, and why you get an ever increasing nosediving problem the more rounds you stuff in the mag, beyond 5 rounds loaded:

Quote:

Angular Gap Under Top Round: Angular Gap When loading a 1911 mag, most

people have noticed that the top round begins to behave differently when the

fifth round is loaded. Up until then, with four or fewer rounds loaded, the

bottom front of the top round is well supported by the upper front of the

round below it. The top round and the round (s) below it are in line contact.

They act as one when you push the nose of the top round down with your thumb.

When the fifth round is loaded, the top round begins to act independently of

the rounds below it. Now, when you push down on the nose of the top round, the

nose rotates down through an arc or angular gap until it closes on the round

below it. There is no longer any brass support under the bottom front of the

top round. This angular gap gets even greater as more rounds are loaded. This

phenomenon encourages nose down feed ramp jams, which has always been a curse

of the 1911 design. When I first started working seriously on 1911 mags, I

thought this angular gap could be eliminated. Currently, based on a lot of my

shop time, I do not believe it can be eliminated in a single stack 1911 mag. I

believe it is a function of the 17.5 degree mag angle, the shape of the ammo

and various individual and collective friction points. David Rice, a shooter,

physicist, observer and thinker from Vermont has the best explanation I have

heard. He believes it’s a conservation of energy thing. Any other

arrangement of the stack of rounds in the magazine would tend to increase the

distance between the top round and the bottom round which would have to

compresses the spring more. Nature won’t be having that. Nature wants the

lowest energy condition. He has a detailed version of this but it is beyond

the scope of these notes. After accepting this angular gap for what it is, I

looked for the biggest factor affecting 1911 magazine reliability. In my

opinion, it’s round height, round height and round height. There are other

important elements in a mag (such as feed lip polish) that have to be right

but a higher top round position is essential to the best mag. The CobraMag

incorporates both higher round position and factory polished feed lips.

Quote:

Try using a follower that doesn't pitch forward, or has very little

movement such as a Wilson or the like. The longer skirt around the follower

will keep that to a minimum... and also keeps the rounds straighter or a bit

upward and not angled downward like what shows in the photo.

IMHO yes the Wilson's followers do help a bit, but only a little, the lower rounds still have the same rear tip-up/nose-down (your perspective) shown on the tripp website, only transferred to the rear. The mag on the right doesn't look like it is as much, but it is, the witness slot is almost at the front of the casing instead of the rear, also as shown on the tripp picture, rounds 2 through 7/8 aren't held in the magazine at the same angle as the top round, nor is the bottom round. I should add, both mags are downloaded by one round to be able to see this easily. Niemi24s photo shows this same effect.

Quote:

Try using a follower that doesn't pitch forward, or has very little

movement such as a Wilson or the like. The longer skirt around the follower

will keep that to a minimum... and also keeps the rounds straighter or a bit

upward and not angled downward like what shows in the photo.

The only mag I have with a non-standard follower is a Metalform with the rounded & skirted follower. The top (7th) in it noses down just as much as any of my other magazines.

Even if the follower can be prevented from tipping down at its front in a full magazine, it won't help simply because the aft end of the follower cannot pull down on the aft ends of the rounds above it.

Set up a protactor at 68.5°, stack up 7 rounds like in the picture, push down gingerly on the top round and observe the behavior of the bottom round. With just light pressure you can make it lay down against the protractor head (follower) or tip it up as shown.

I had also observed that the follower begins to lose its ability to support the cartridge nose when 4 or 5 cartridges are loaded.

Maybe another way to think or visualize the situation is this: Picture an empty magazine with the follower & feed lips about horizontal; put in 1 round and the follower goes not only down, but aft a little bit; put in the second round and the follower goes down - and aft - again; by the time the 7th round is put in, the front of the follower is aft of the aft end of the top round as shown here: http://i129.photobucket.com/albums/...can0016btxt.jpg It is, I think, physically impossible for the follower to hold this top round up against the feed lips with any meaningful force and prevent nosediving. And I don't think any change in the follower angle, spring strength or anything else will help - except for making the gun's grip angle closer (much closer) to the vertical.

great picture

great picture

Quote:

And I don't think any change in the follower angle, spring strength or

anything else will help - except for making the gun's grip angle closer (much

closer) to the vertical.

How can Glock with an even more obtuse grip to frame angle manage to keep the rounds supported in the magazine and a slightly nose up when they present in between the feed lips? I guess it is a combination of the follower design and of the self arranging nature of the double stack magazine design? Because with the more obtuse grip angle and the slightly tapered 9mm rounds you'd think the rounds would be nosediving all over the place..For that matter why don't the .45 rounds in a USP/HK45 nose dive, those guns have the same essential grip angle as the 1911.

Accurate or not, Tripp argues that a double stack mag with a proper follower design fixes the nose diving problem. But looking at that picture above, maybe lengthening the grip/magazine, so that the rounds can lay flat on the follower and stack nicely on top, would also solve the problem?

Quote:

How can Glock with an even more obtuse grip to frame angle manage to keep

the rounds supported in the magazine and a slightly nose up when they present

in between the feed lips?

I know a little about the 1911 and absolutely nothing about Glocks. The angle of the 1911 magazine well measured from the vertical axis is 17.5deg. The term "more obtuse" to me means closer to the vertical. If, then, you mean the Glock's magazine well is less than 17.5° from the vertical axis, then the answer's easy: the Glock follower's more directly below the top round in its full magazine.

However, if you mean the Glock's magazine well is more than 17.5deg from the vertical axis, I have no idea. Magic?

Quote:

However, if you mean the Glock's magazine well is more than 17.5° from the

vertical axis, I have no idea. Magic?

On my G26 the well axis is at approx. 20deg. When the magazine is inserted in the gun, the top round presents at approx 7deg upward from the slide ways, then as the slide cycles in recoil, the barrel also tilts downward at the same 7deg angle although just slightly higher, making an almost straight into the chamber feed. Very similar the the 1911's last round feed, just for all the rounds, because of the barrel's downward tilt.

P.S.: Just noticed the image is reversed from left to right. Some dummy did a vertical flip instead of 2 left or 2 right rotations!

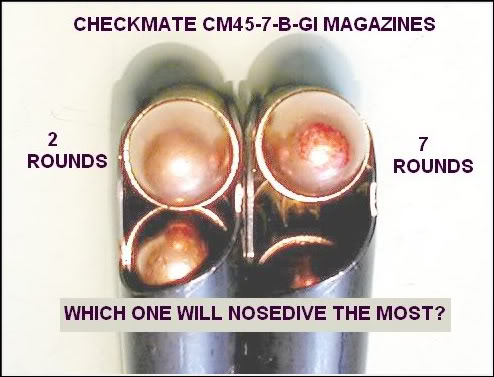

The gap shown in the pic in Post #35 is not peculiar to the Checkmate magazine, as shown here:

At least I got the image properly oriented this time!

Niemi, here are three 8 round mags, all I had available were parallel wadcutter lips. The left one is a Sig with metal follower no dimple, the middle is a Wilson 47D with polymer follower and the right is a Wilson 500 with polymer. The gap on the top round is .098, .096 and .096. It would seem that the top round gap increases with the number of rounds, the same as in loading the magazine. I wonder what a 10 rounder's gap would be...

Quote:

I wonder what a 10 rounder's gap would be...

Me too! Hmm-m-m-m. Wonder what magazine capacity it would take to get a round to nosedive so much it would hit the front of the mag tube - and never make it to the frame ramp!!

Now there's something to wonder about, huh? (Ain't it fun to wonder?)

Quote:

Ain't it fun to wonder?

Yes, Niemi it is. I spend a lot of time doing this with this 1911 platform, then after reading many threads and combining the knowledge of all, usually end up with a "heel of hand thump to the forehead" followed by the word DUH!!!

I know there have been statements about the dimple on the magazine. 1911tuner, whose knowledge and experience I greatly respect, states that it is a redundancy that helps prevent the follower from moving to the left during slide lock. While logman states that it can't come into contact with it, as do you, with your informative illustrations and drawings.

While comparing your "contest photo" with my previous 8 round magazine photo, I was just wondering if the purpose of the dimple could be to help prevent nosedives by providing just a smidgeon (technical term ) of front case support/alignment during feeding? In many photos I've seen, that dimple is located just under the centerline of the top round in the magazine and just made me curious is all.

Is it possible the dimple could be there to allow the mag to be inserted into the magwell more smoothly, in other words with the dimple in the mag the mag slides past the mag release more smoothly when inserted into the gun?

Quote:

Is it possible the dimple could be there to allow the mag to be inserted

into the magwell more smoothly...

IIRC, that was the general concensus of opinion in the "Do I Need A New Slide Stop?" thread a month ago. That's all I can see it does based on this:

Maybe JMB or the Army put it in there for some other reason, but I have no

idea what that reason might be.

Maybe JMB or the Army put it in there for some other reason, but I have no

idea what that reason might be.

Quote:

I know there have been statements about the dimple on the magazine.

1911tuner, whose knowledge and experience I greatly respect, states that it is

a redundancy that helps prevent the follower from moving to the left during

slide lock. While logman states that it can't come into contact with it, as do

you, with your informative illustrations and drawings.

While comparing your "contest photo" with my previous 8 round magazine photo, I was just wondering if the purpose of the dimple could be to help prevent nosedives by providing just a smidgeon (technical term ) of front case support/alignment during feeding? In many photos I've seen, that dimple is located just under the centerline of the top round in the magazine and just made me curious is all.

This could get a bit confusing. I think in the first paragraph, above, you're referring to the dimple on the right hand side of the magazine tube - the same one as Toolman.

In the second paragraph, to the dimple in the middle of the top of the follower. If so, have you read the "The Dimple" sticky?

Quote:

Is it possible the dimple could be there to allow the mag to be inserted

into the magwell more smoothly, in other words with the dimple in the mag the

mag slides past the mag release more smoothly when inserted into the gun?

Another DUH! moment, I was aware of that too, just forgot to mention it in my question.

Quote:

This could get a bit confusing. I think in the first paragraph, above,

you're referring to the dimple on the right hand side of the magazine tube -

the same one as Toolman.

Sorry Niemi, yes I was referring to the one on the magazine body in both statements. I was just thinking about it (a dangeruss thing sometimes ) and was musing about possible under centerline case support in the front of the cartridge, which may continue along as the cartridge is feeding, and even just a little after lip release to help keep the cartridge against the left side of the breachface aiding and aligning the round as it slips under the extractor, and working with the dimple on the mag. follower in aiding the round to roll over into the correct feed position. Whew, there's some smoke leaking out now, I better stop from the overload!!!

I suppose it really would keep the feeding cartridge from going to the right as far but, at least with the mags I've got that have them, only after the round has already nosedived (nosedove?) a little bit. I think once the round hits the frame ramp and the bullet nose is entering the chamber, the mag tube dimple is well below that round and cannot affect it any longer. (I think)

[sniff] Uh oh, I smell smoke here too!

Tuner's conclusion, is that the dimple affected the last round. Giving it a bit more pressure on the last round so it would stay put during recoil etc.

I find that the parallel feed lips, ala Semi-wadcutter, does the same thing. There's more contact on the case to hold it, and keep it in place.

Not sure if anyone will ever know for sure why the dimple is there.

Here's CMC Power 10 mags full, and the gap is .140"

Quote:

Not sure if anyone will ever know for sure why the dimple is there.

What's always mystified me about the dimple is its shape.

Not just a simple little round bump, but more like a tiny wedge of lemon laid flat and seemingly oriented just to make the first round more difficult to insert!

And not just any old wedge of lemon, but a 30deg one!

Good grief, .140" gap, I'll bet the stars have to be lined up to keep that from a nosedive.

It's interesting to watch the gap grow as you load the mag. These tens actually work pretty well, but the first out is the hardest obviously, and a good test of the tune of the gun.

I meant the angle between the bore/barrel line/axis and the grip, with the point of the angle pointing up and back

But based on the Niemi illustration, where the back of the rounds are hitting the back of the mag, how about the idea that if the magazine was longer front to back, and the rounds fit in there so that the rear of the rounds didn't hit the back of the mag, they would then seat better horizontally and therefore not induce the nosediving effect; anything to that idea?

Yeah, and that last round in the 1911 (provided that the gun is well put together) just zips in the chamber. I mean my 1911 will feed an empty case when I load it in there. My USP can't even do that. I haven't tried it yet with my Glock.

Anyway, I guess this is why the Colt 1903 has the straight grip style? I would think no round nosediving with this one?

Looks super cool except for I would think it makes for more muzzle flip

Anyway I think a work of art that 1903 (and I'm not talking about the engraving either)

Quote:

...how about the idea that if the magazine was longer front to back, and

the rounds fit in there so that the rear of the rounds didn't hit the back of

the mag, they would then seat better horizontally and therefore not induce the

nosediving effect; anything to that idea?

I think it would do the trick, but then (with the same grip angle) you'd have to also widen the grip from front to back to get, say, 7 rounds stacked up more vertically.

While the grip might only need to be, as a guess, about 1/4" longer, I think the magazine needed to get the cartrige column to stack up sort of corner-to- corner inside it would be quite expensive to make.

Gun might also be a real challenge for folks with small hands - unless you did the whole thing for the shorter 45GAP.

Interesting thought about a shorter cartridge.

Conventional wisdom, at least as I've been exposed to it, says that 1911's run best with the .45 ACP/10mm/.38 super rounds, as they are of the same relative length of the original .45 ACP, the round that the gun was originally chambered for, BUT, could the rounds stack up better in the mag, and eliminate some of the nose diving problem if, like you are suggesting, shorter rounds are used (eg, .40 S&W, 9mm), but in a standard 1911.

Do any of you guys have a .40 S&W 1911 magazine to show us how the rounds stack up in there?

I could be wrong here, but it seems to me that your questions on the first couple pages imply another question. Can the 1911 be tweaked (specifically speaking, the angle of the round as it relates to the barrel ramp) to function similar to how USPs and Glocks feed, in order to increase reliability?

IMHO, the answer to that question is that there isn't really a need to. The 1911 feeds differently from Glocks and USPs (more of a straight shot into the chamber) by design. Even though it seems like rounds are smacking into the frame ramp and getting congested, the 1911's design specifically calls for the rounds to do so, and the gun is ultra reliable.

IIRC, there are at least two main reasons why the 1911 was designed in this manner. First, round contact against the frame ramp helps to lessen some of the slide velocity upon return to battery. This lengthens the lifespan of the barrel feet, lower lugs, slide stop pin, and slide stop pin hole. Secondly, the round is held captive during the entire process of feeding. 1911Tuner has named this a controlled feed design: http://forum.m1911.org/showthread.php?t=9178

The main advantage of a controlled feed design is the ability to shoot the gun from odd angles, even upside down, possible because the round is held captive during the entire feeding process. Guns that don't have this may also be fired in this manner, but there is a moment (although a small, fleeting moment) where the round "floats" and may be adversely affected by gravity to the extent that the round jams.

The disadvantages of such a feeding mechanism didn't really manifest themselves until the use of different bullets became popular. Because the geometry of the frame ramp and barrel ramp was designed for ball ammo, HPs, SWCs, and WC could not be expected to behave as reliably as ball ammo. (Ball ammo from the original late release tapered feed lips can be expected to be utterly reliable.)

Because of this, many companies have new mag designs that present the round higher or closer to a straight shot to the chamber. Most of the changes are to the feed lips; such as early release, parallel, and higher angles (for a straighter shot into the chamber). Generally speaking, these are all compromise designs because they do increase the reliability of the more exotic bullet shapes at the expense of losing some of the controlled feed.

A HP with a similar or exact ogive as ball ammo from a late release mag retains the controlled feed function and may be the best of both worlds.