Got myself a brand new Bar-Sto barrel, it is drop in.

After I put it in the slide I noticed this..

The clearance is around .008 to .009, I have not yet filed the lower lugs, so the frame is still hanging on the rear a little. Is the clearance normal?

I fired the gun, more than 50 rounds I think, and experienced no failure.

Is there a need for me to alter the barrel aside from the lower lugs?

Quote:

Is the clearance normal?

If the picture was taken with the gun fully assembled (including the recoil spring) and there's no gap between the barrel's hood (a.k.a. chamber extension) and the breechface... yes it's normal.

Q#1: When in battery, is there a gap between the barrel hood and breechface?

Quote:

Is there a need for me to alter the barrel aside from the lower lugs?

If, as you say, you have a drop-in barrel...

Q#2:... why do you want or need to alter the barrel's lower lugs?

If it's because the slide hangs back over the frame at the aft end, that's taken care of by blending the slide to the frame - not filing the lugs so the barrel and frame sit farther forward when at battery.

Q#3: Don't the Bar-Sto instructions mention that?

If the picture was taken with the gun fully assembled (including the recoil spring) and there's no gap between the barrel's hood (a.k.a. chamber extension) and the breechface... yes it's normal.

There is no gap between the hood and the breachface. I noticed the hood of Bar-sto is longer compared to the hood of the Fusion barrel. When I took a look at the Kunhensen book, it seemed that NM barrel hoods are quite longer.

Q#1: When in battery, is there a gap between the barrel hood and breechface?If, as you say, you have a drop-in barrel...

I'll check this later and update you.

Q#2: ... why do you want or need to alter the barrel's lower lugs?

The rear of the slide hangs and I cannot engage the thumb safety, if it is not the solution, can you give me other solution?

If it's because the slide hangs back over the frame at the aft end, that's taken care of by blending the slide to the frame - not filing the lugs so the barrel and frame sit farther forward when at battery.

Q#3: Don't the Bar-Sto instructions mention that?

I don't have the Bar-Sto instruction manual.

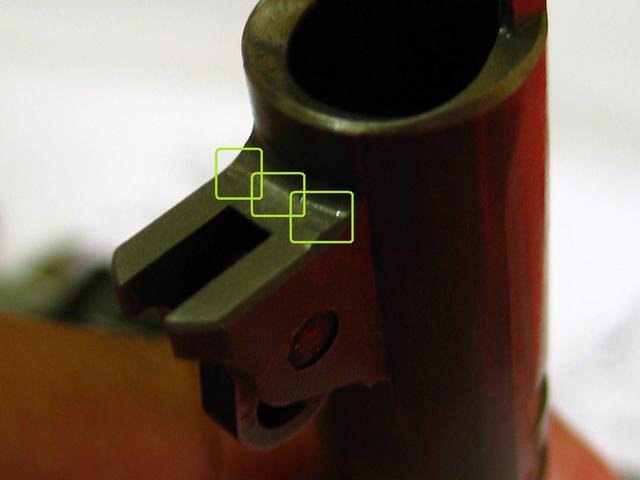

Pics with chamber loaded.

No gap between breechface and barrel.

The first photo pretty clearly shows what appears to me to be a gap. The gap only needs to be a couple of thousandths of an inch. Yours is big enough that I can see the cartridge rim through it. It definitely is not in contact.

I tried to insert a shim, the smallest one, no gap between hood and breechface.

What you can see is oil between the breechface and barrel.

The pics shows loaded chamber.

If there is indeed, as you say, no gap between the hood and breechface when in battery (and I don't see any in your first pic in Post #4) that's good.

NM barrel hoods are purposely made too long to allow the barrel to fit in the slide. This is so the NM barrel can be fitted to the slide with little or no fore-aft play in the slide (after equalizing the verticallocking lugs). As a drop in barrel, your Bar-Sto's hood probably didn't need any fitting. That's why it's called a drop in. Because of this, your new barrel probably does have some fore-aft play in the slide.

If, when in battery, the slide sits too far back to allow engagement of the thumb safety, Kuhnhausen (somewhere in one of his volumes, IIRC) gives a minimum barrel lug front-to-back dimension.

You should find that dimension in Kuhnhausen and see if the lugs have enough "spare" material to allow the thumb safety to engage.

Head-spacing measures? How do the upper lugs of the barrel look, after cycling the slide a bit, with Sharpie marks on the lugs?

Lugs looked perfect, I fired more than 50 rounds in it.

When John asked, in Post #8, how the lugs looked with a Sharpie he was asking which of the three barrel lugs make contact with their corresponding slide lugs when the barrel is forward in the slide.

In addition, how much of a gap is there between the hood and breechface when the barrel is forward in the slide? That dimension will tell you the difference between the static (not yet fired) and dynamic (just fired) headspace.

The business of checking barrel & slide lug contact is explained in this:

http://forum.m1911.org/showthread.php?t=25473

But with a drop in barrel you don't supposedly don't need to find out how much to trim the hood - your hood is already supposedly already short enough to allow the barrel tofit into the slide.

Supposedly. You forgot the word "supposedly".

Hi, thanks for the replies, I attached additional pics and posted some additional questions.

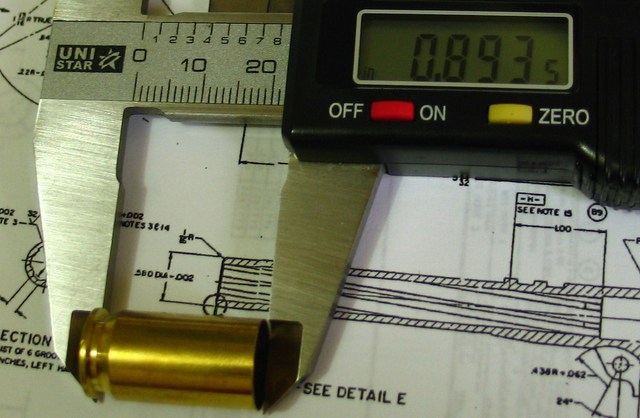

I tried to test an unfired shell, attached pic is the measurement of the shell.

The clearance it made with the barrel hood is around 0.011 inches.

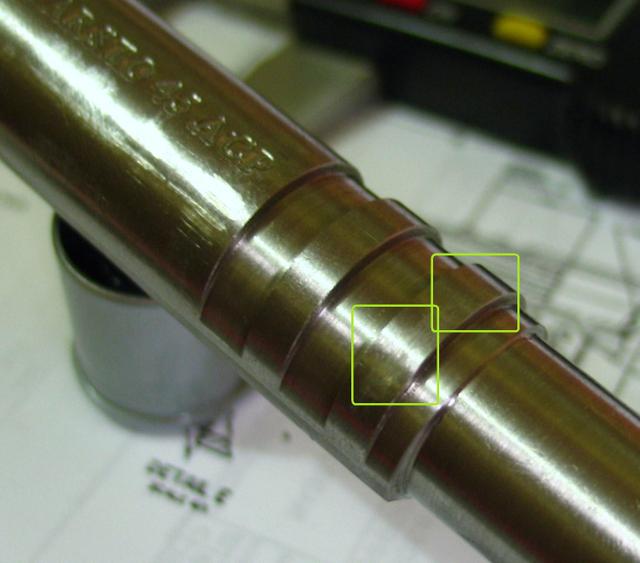

Below are the scratches made in the barrel when I test fired it. About 50 rounds.

Below is the impact markings from the VIS.

Is there a need for me to file this part? The VIS of the frame has already the so called bowtie cut, or what you called it?

No... don't file this part. The radius (what I presume you are questioning) is necessary for the lugs to last through impact. It resists cracking in the corner and is a design in stress relief.

It is my understanding that the barrel lugs are not supposed to hit the VIS. If there is noticiable peening than the barrel should be relieved. Hitting is one thing and touching is another.

All looks well, the scratches on the chamber area are normal, and the impact area looks good also. Yes, it does hit and is what stops the barrels rearward motion at link down.

How about the clearance in hood and the unfired shell?

I don't have a GO and NO GO gauges here, so I posted a pic of the length of the unfired shell and the clearance it had with the hood, is .010 to .011 ok?

Quote:

How about the clearance in hood and the unfired shell?

I don't have a GO and NO GO gauges here, so I posted a pic of the length of the unfired shell and the clearance it had with the hood, is .010 to .011 ok?

Not a definitive check as the hood end to breech face with the barrel forward is unknown. With slide, extractor out, barrel with case in chamber and bushing in place slip feeler gauges between case head and breech face and add the feeler gauges to the case length for head space.

Feeler gauge is the same.

I recently instaled a new barrel and bushing on my 1927 Colt. After reading this thread, I noticed that even though the lugs look very good (300 rounds on new barrel) that the barrel hood is not touching the breechface.

I measured the distance with the action closed and there is approximately .006" between the hood and the breechface. After closer inspection, it appears that the lugs above and below the extractor are contacting the barrel and limiting its aftward movement.

The barrel drops into the lugs without any problems, so would the correct course of action be to stone the section of the barrel that is contacting the extractor bore lugs?

This is not unusual for an over cut drop in barrel, the breech blocks should not touch the barrel chamber face, the hood extension should be holding the barrel as far forward in the slide as possible and still allow it to drop by gravity. Putting shim or feeler gauge between the hood and breech face with the slide back enough to slip in progressively thicker and close til it can't return to battery will give you the dimension of how short the hood is for your gun. I'd guess it's between .015" and .020".

Removing metal from the barrel chamber face will allow the barrel to come back even further before firing and then the barrel will be snapped forward until the lugs stop it, better to be in that position to begin with. Your hood is short.

The barrel drops into the lugs smartly without 'springing' and there is no perceptual aft movement when pressure is applied to the barrel. When cycled without a recoil spring, the action is velvet smooth. The barrel drops quickly away and is well clear of the slide before any aft movement takes place.

Should I stone the right side of the chamber that is contacting the lugs above and below the extractor to allow the barrel to come aft?

What would you recommend? I thought I read in this thread that you want the chamber contacting the breechface?

Shoot it and be happy. Wonder what the head space is when the barrel is forward? Replace it with a better fitting barrel. A Kart GS fit or Easy fit are reasonably priced and good quality.

This barrel is an unknown that I have had on the shelf for years. There are no markings on it and my originl barrel had no riflings left, so this was a quick fix so to speak.

A Kart barrel you say?

Don't forget that you're dealing with what's no doubt a gun & barrel having Army Ordnance specs - not one with a fitted barrel.

In a gun with a hard-fitted barrel:

* The hood holds the barrel as far forward in the slide as the vertical locking lugs will allow,

* There will be some (perhaps considerable) gap between the breechface guide blocks and the chamber face (on both sides) and

* The barrel will have very little (if any) fore-aft play in the slide. But...

...in the average run-of-the-mill 1911 with Ordnance spec parts:

* The barrel hood never comes in contact with the breechface,

* The barrel is driven driven forward and up into battery by contact between the breechface guide blocks and the chamber face and,

* The barrel will have about 0.008" total fore-aft play in the slide.

Whacking on the chamber face merely to get the hood into contact with the breechface will to nothing but increase the amount of fore-aft play the barrel has in the slide. It will also allow the slide to sit farther forward on the frame when the gun's in battery and could make thumb safety engagement difficult or impossible.

There is evidence of contact between breechface guide blocks and chamber face and there is .006" gap between hood and breechface.

Whoa! What do you think of that barrel ramp Niemi?

Quote:

...there is .006" gap between hood and breechface.

It just so happens that (when in battery) the hood/breechface gap of a USGI M1911A1 will be 0.006 +/- 0.004 inch.

So yours is right at mid-spec!

Quote:

Whoa! What do you think of that barrel ramp Niemi?

Gee, Log, I didn't even notice he'd posted a pic until you mentioned it!

Looks kinds dark in there. Lemme copy his pic and see if I can work some magic on it - I just love that "gamma" button!

Well, here it is: I've seen worse ones - lots worse. The few little nicks on the bottom edge shouldn't hurt anything.

A view looking down at about 45 deg might tell more.

I apologize for the quality of my photos.... Yeah, I noticed the ramp wasn't square, but its relation to the feed ramp is in spec. After shooting the gun, with 300 rounds of Federal Hydra-Shok, I was impressed.

The gun was super accurate and functioned in every possible firing position, including upside down, double taps and 8 round strings at 1 yard from the position of high retention.

The gun's performance made me decide to put a little work into it.

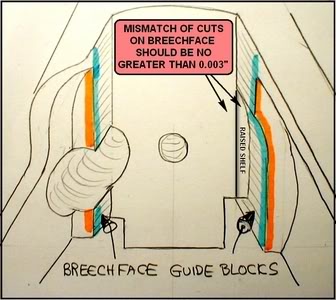

What are these "breech blocks"?

Quote:

What are these "breech blocks"?

They're the things the case rim fits in between when the case head in against the breechface.

The barrel I showed is not hitting the guide blocks, is this normal? Only the barrel hood touches the breechface.

Quote:

The barrel I showed is not hitting the guide blocks, is this normal?

What is "normal" depends on the barrel.

* A plain old GI barrel will contact the guide blocks because the hood is shorter than the depth of the guide blocks.

* National Match and other hard-fit barrels have longer hoods which must be trimmed to get the barrel to fit in the slide. These barrels will contact the breechface.

Your Barsto barrel's hood must be long enough to contact the breechface and that's just fine.

There may even be some barrels that make contact with both the breechface and the guide blocks, but I think that would be a little unusual.

Just make sure you've got adequate vertical locking lug engagement and that the gun passes the timing tests. Then, shoot & enjoy it!