I have a RIA full size 1911 which I purchased new. I have about 600 rounds through it. I have several different magazines. I was having problems with it since I have had it, first failure to return to battery. The cartridge was chambered but the slide was about a quarter of an inch out of lock. I checked the chamber and head space and it seems correct.

I noticed that the link pin was dragging. The end was sticking out slightly and "mushroomed". I used a file to clean up the end and the link now works correctly but was still having the slide hanging up.

I checked the original recoil spring against a Wolf spring and found the RIA spring was about 2 inches shorter. I replaced the recoil spring with a Wolf 18 1-2 pound spring and started getting hard 3 point jams more than 50% of the time.

I lightly polished the breech face and checked the extractor. The hooked end was pretty ugly. I profiled the end and set the tension with my weigand tool. I would set the tension and the gun would run OK with WWB hard ball 75% of the time but after a couple of mags it would start having failure to extract issues. The RIA extractor seems very "soft" compared to a spare extractor I have. (Not a part that should be MIMed I think). I am replacing the extractor but am waiting for a new FPS (the factory one is very loose).

I think the problems are a combination of things; The dragging link; The weak recoil spring; A rough breech face and a bad extractor. I think there is one more issue though. The feed ramp to barrel gap seems to be excessive. Could this be part of the problem?

RIA

RIA left Colt right

RIA

Colt

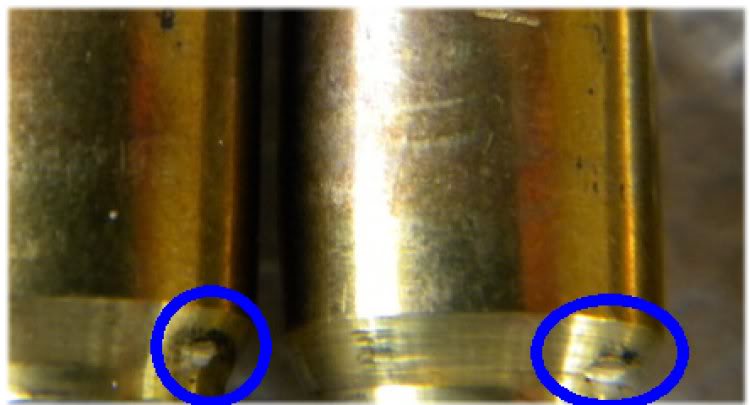

You may want to check to see if there is clearance between the extractor claw nose and case bevel like this:

otherwise the extractor will dig into the case like this:

And hold the case off the breach-face like this:

which can case FTRB on pistols with tight chambers.

Break-over angle could use a bit of work.

The extractor does fit the extraction groove on the case. (I am going to replace the extractor because it wont hold tension) I have read that there is supposed to be a 1/32 gap between the feed ramp and the barrel. This gun has a 1/8 gap. I was wondering if this could be the cause of some of the feeding problems.

1/32" is the minimum... it's to allow the round to jump off the frame ramp, bounce off the barrel ramp, and into the chamber. In other words, 1/8" is just fine.

What does your contact look like on the barrel feet, the slide stop, and the top lugs of the barrel?

Quote:

I replaced the recoil spring with a Wolf 18 1-2 pound spring and started

getting hard 3 point jams more than 50% of the time.

If you shoot nothing stronger that WWB, recommend you replace the 18-1/2lb spring with a new standard 16lb spring. The stronger spring does nothing but put additional impact stresses on parts not designed for additional stress such as the slide stop pin and the barrel's lower lug stops/feet. A stronger spring may also just cover up other feeding problems at the expense of the gun, but didn't seem to have helped your gun at all.

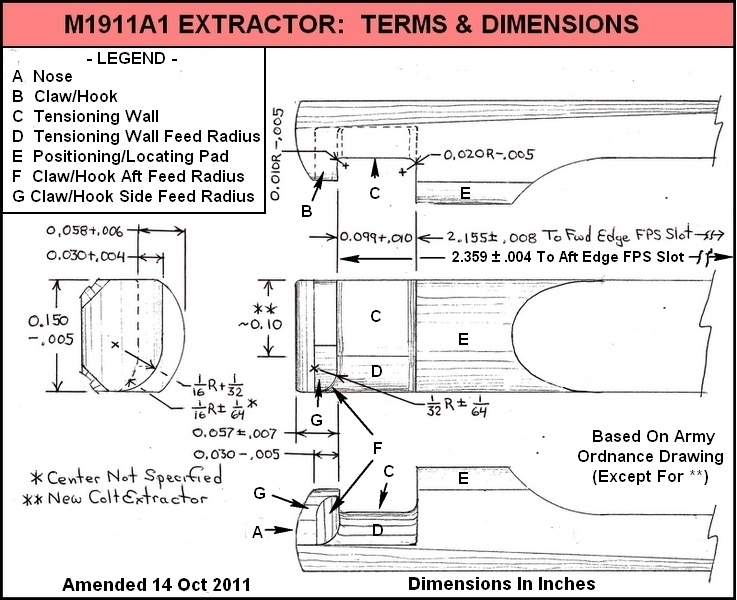

Your new extractor may well cure the problem because when 1/4" from battery (lock) the case rim is well under the extractor. Here's what the Army Ordnance blueprints show the extractor nose should look like:

But I don't think your frame ramp/barrel ramp gap is too excessive. And even if it was, I'm not sure it could cause the problem you're experiencing.

Quote:

I have read that there is supposed to be a 1/32 gap between the feed ramp

and the barrel.

You read it simply because that's the popular mantra amongst custom builders and internet gurus. Built according to Army Ordnance blueprints, the average M1911A1 will have the surprisingly small gap shown here (the sheepish should avert their gaze):

Is it supposed to be 1/32"? That, I think, depends on who's doing the supposing!

Edit: Of course, the M1911A1 is designed to shoot nothing but ball ammunition.

I don't see anything unusual but I'm not an expert.

The barrel lugs appear normal to me.

Slide Stop

Frame

Barrel Ramp

I have a 16 pound spring on order.

What exactly is "break-over angle"?

A dumb question; besides camming the barrel up and down what else do the barrel feet do? Do they also form part of the lock up? kind of like an over center lock.

I am actually enjoying troubleshooting this gun, best way to learn how something works is to fix it.

Those pictures look fine to me. Your frame shows an upside-down horseshoe shaped mark at the top of the Vertical Impact Surface (VIS) that is an indication that the barrel hits the VIS thus stopping its rearward motion instead of the barrel link. This is good.

The upper barrel lugs look sharp.

The slide stop pin show typical non-match fit, production fit marks where the link rides.

The barrel ramp looks good.

The top of the chamber look free of heavy machine tooling marks that may inhibit chambering a round.

Others may chime in but thats what I see in the pictures.

Quote:

...besides camming the barrel up and down what else do the barrel feet do?

Do they also form part of the lock up? kind of like an over center lock.

Although you never know it by reading stuff here on the internet, in the average Government Model M1911A1 the barrel feet do NOT cam the barrel up and down - the link does. As designed and as shown by the Army Ordnance blueprints, the barrel's lower lugs (feet) contact the slide stop pin only when the gun reaches the final battery position, as shown here:

PICTURE 404

Gunsmith-fitted barrels are different and may get cammed up by the lower lugs or by the link. However, when in battery the feet of a properly fitted gunsmith-fitted barrel will rest on (and be supported by) the slide stop pin.

But no matter what kind of barrel or how it's fitted, the stops on the lower lugs are what halts the forward motion of the barrel (and thus the slide) when the gun reaches battery. In addition, the aft vertical surface of the lower lugs halts the rearward motion of the barrel by contacting the VIS when the barrel links down after the gun is fired.

Would like a picture of the front of the barrel feet, and one of the slide stop from this angle...

if the slide stop were in the gun, and you were looking at it from the left side (muzzle points to your left), about 2:00-3:00, straight on from that angle. Does that make sense? What I'm wanting to see is the contact of the slide stop with the barrel feet.

And this is how some "match fit" barrels use the barrel knees to support the barrel by riding on the slide stop pin at point "B".

Here is another style match barrel lug profile that shows how the barrel lower lugs (knees) push against the slide stop pin to raise the barrel into lockup. (look at the bottom of the link hole)

BUT these barrels require a lot of work and attention to detail.

Quote:

I have a 16 pound spring on order.

Excellent!

Quote:

What exactly is "break-over angle"?

Don't mean to words in Traxxis' mouth, but I think he means the top corner of the barrel ramp. It's often called that because it's where the cartridge slides along when breaking over to the horizontal position on its way into the chamber. And because the cartridge (actually, the case) is sliding there, that top corner needs to be pretty smooth - and with a slight radius not exceeding 0.03".

Edit: And don't get your hopes up by thinking your gun has any kind of lower lug/slide stop pin contact other than what's shown in Post #11. Your gun's an RIA - not a $1,500 match grade shootin' iron with a gunsmith-fitted barrel!

Aha! These latest photos show the knees of the lower lugs are crashing into the slide stop pin. Not good because that can cause the barrel to lurch upward and not ride the link smoothly into battery. Dress down those flat, shiny areas (shown just forward of the slide stop pin in your third photo) to avoid contact there.

For clarity:

Thanks. I'll get that fixed. I can feel a slight drag when the slide stop passes over the knee area.

The M1911 is design to use a controlled feed principle. While the round is pushed forward by the slide it bounces off different surfaces of the pistol to eventually end up in the barrel chamber. This is the job of the recoil spring.

Any "unintended" drag will rob return spring energy and jeopardized a return to battery. Your crash marks together with other inspections like the one I posted about extractor claw nose clearance should identify any unintended drag.

Eliminating unintended drag will put the pistol in a "as designed" condition that most often solves a lot of cycle problems.

One last thing, Traxxis hit on this but, I saw something. You're supposed to have 1/32" min. between the top of the frame ramp and the bottom of the chamber lip. Your RIA is fine however, the Colt looks too close. Looks like you have about half of what you should have. But, if it feeds okay, all is good with the world. Thought I'd mention that.