FWIW, these old threads http://forum.m1911.org/showthread.p...ht=feet+battery and http://forum.m1911.org/showthread.p...ht=feet+battery contain drawings based on an Ordnance blueprint last updated in 1973 - the same one as in our Tech Issues section.

A recently obtained blueprint last updated in 1994 shows significant changes to the "knee" area of the barrel's lower lugs as shown here:

PICTURE 404

Pop Quiz: Does a mid-spec Gov't Issue M1911A1 ride the link all the way into battery?

I know it sure looks a little odd, but here's the latest blueprint data (last updated in 1994) upon which the above drawing is based:

PICTURE 404

At first glance it might seem like the center of the 0.173R - 0.010 knee curve is centered on the link pin hole's center, but it can't be. The two adjacent surfaces are only 0.14 and 0.162 inch from the link pin hole's center, and would put the "knee" out where there wasn't any metal! Concluded (wrightly or wrongly) that the knee radius must thus be tangent to both the adjacent surfaces and it was drawn that way.

Anybody see anything I'm missing?

Thanks for posting these details. This subject has interested me for some time also; I keep coming up with material that suggests that the lower lug radius should be clearanced from the slide stop pin everywhere except for the final 1/8" of movement into battery. Even this small area of contact (if the barrel actually stands on the slide stop pin in battery) is considered to be a NM hand fit barrel. It is easy to accept no contact during linkdown, but ideally shouldn't the slide stop pin ride the lug radius as it links up? If you look closely, some of Kuhnhausen's drawings show a lug radius centered below the center of the link pin, but without any dimensions given.

How could it not be riding the link? ...accumulated tolerance?

What is the .173 measurement? ...and how?

Quote:

How could it not be riding the link?... accumulated tolerance?

Although I've not done the math, I don't think tolerance stacking would reduce the 0.009" mid-spec value to much below 0.005"

Quote:

What is the .173 measurement?

That's the mid-spec value of the "0.178R - 0.010" dimension for the radius shown in Post #2.

Quote:

...ideally shouldn't the slide stop pin ride the lug radius as it links

up?

Not really sure, so allow me to ramble a bit. For a hard-fit barrel I think there's four different ways the barrel can get shoved up into battery by the slide:

1. Constant contact between the lug and SS pin from the time the barrel gets moved forward on the bed by the slide. The link never get into compression. The extreme opposite of this is...

2. ...the barrel rides the link almost all the way into battery. The link is in compression from the time the barrel's moved forward on the bed by the slide and goes slack (or barely slack) just before (or just when) reaching battery - when the link deposits the lower lugs onto the SS pin.

3. Some combination (say a 50/50 mix) of these two:

3A. Lugs ride the SS pin, say, half way into battery where the link goes into compression lifting the lugs off the SS pin and later (just before or at battery) goes slack upon depositing the lugs back onto the SS pin. Or the opposite where the...

3B. Barrel rides the link, say, half way into battery where the link deposits the lugs on the SS pin for the last half of the trip to battery.

In the Ed Brown barrel fitting instructions (thanks again for those), his goal is to reduce the disturbances to the barrel when the bullet's in between frame and barrel feed ramp contact - for smooth feeding. Seems to me this is a very worthwhile goal and all but eliminates 3A & 3B due to the fussy nature of making the transition a smooth one - the arc of the inside of the link hole would have to tangent to the lugs at the transition point, I think.

That leaves 1 & 2. IIRC, Tuner has mentioned the barrel is less likely to hop up (and disrupt smooth feeding?) if method 1 is used. However, I don't know (or remember) whether Tuner actually hard fits NM barrels that way. Ed Brown, Kuhnhausen (Vol II, page 129) and Hallock (page 168) use method 2.

So is method 1 the ideal method? I don't really know. But...

...do hard fit (NM) barrels come with enough extra metal in that area of the lugs to allow method 1 to be used?

Yes they do, and that goes double for Schuemann barrels.

There might be some useful clues if we take into account what changes in barrel fit are likely to happen during the first hundred rounds or so.

Schuemann gives that with their products, yet allows for an almost a precision drop in fit... of course depending on the specs of the slide/frame.

..and Schuemann barrels are made here in my front yard. I shoot with the owner. Lucky me!

I like to fit/shape the lower lug so that the slidestop pin contacts the link and the lug evenly just as the pin makes it around the... knee... which is a useful descriptive term, Dan, and thanks very much for it. For initial barrel rise, it's a good idea to have it ride the link just a wee bit as it starts, though... to prevent dinging the lug against the pin. I try to hold that to a minimum. No more than about .003 inch. Once the barrel has started to cam up, I don't want to see it ride the link at all, and much prefer that it does so by the lug and pin interface.

Sometimes, that's not so easy to achieve, though, but as long as the barrel doesn't ride the link hard and high...and doesn't stand on the link at all when in-battery... the gun will work fine and never give a problem. Since I don't fit barrels "Match" tight... either vertically or horizontally... it serves my purposes well, and it requires good ammunition fired from a rest to see any practical difference in accuracy. My accuracy standards aren't that high, as my main focus is on reliability. If the gun will shoot into an inch at 25 yards with good ammo, I'm as happy as a duck on a clean pond.

Felt all bright-tailed & bushy-eyed this a.m. after coffee #3, so calculated the minimum vertical gap between the feet and SS pin to be 0.0051". This with each of the pertinent specifications (3 for the link, 3 for the barrel and 1 for the SS pin) selected to produce a minimum gap in this in-spec Gov't Model M1911A1 (with no NM or fitted parts).

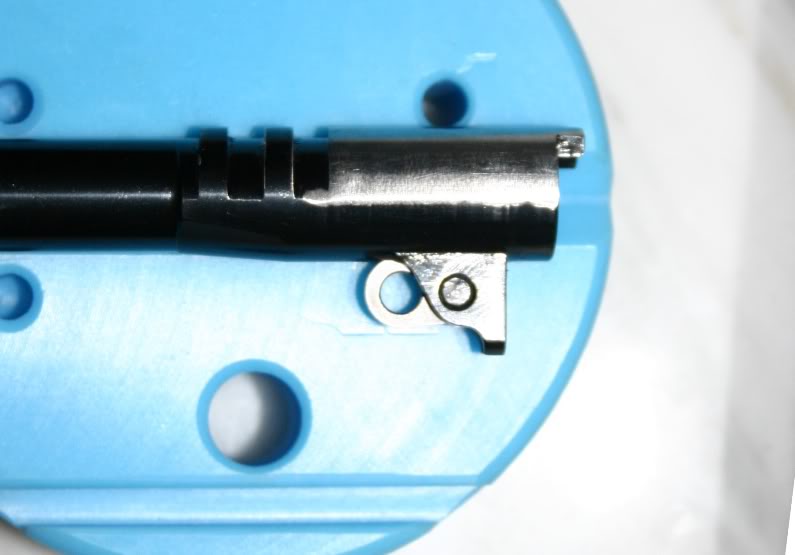

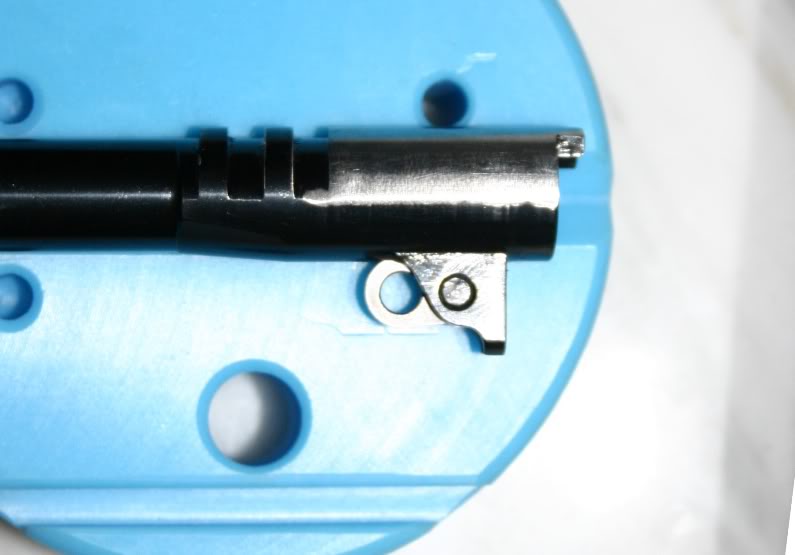

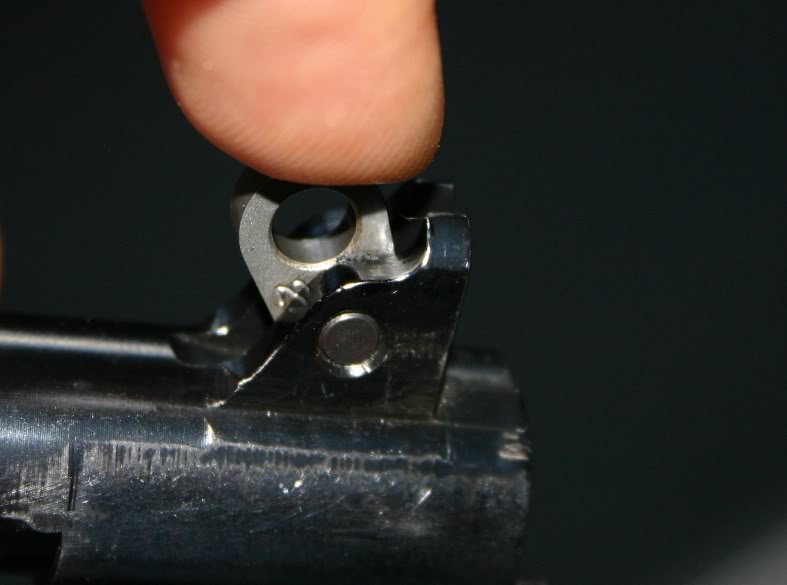

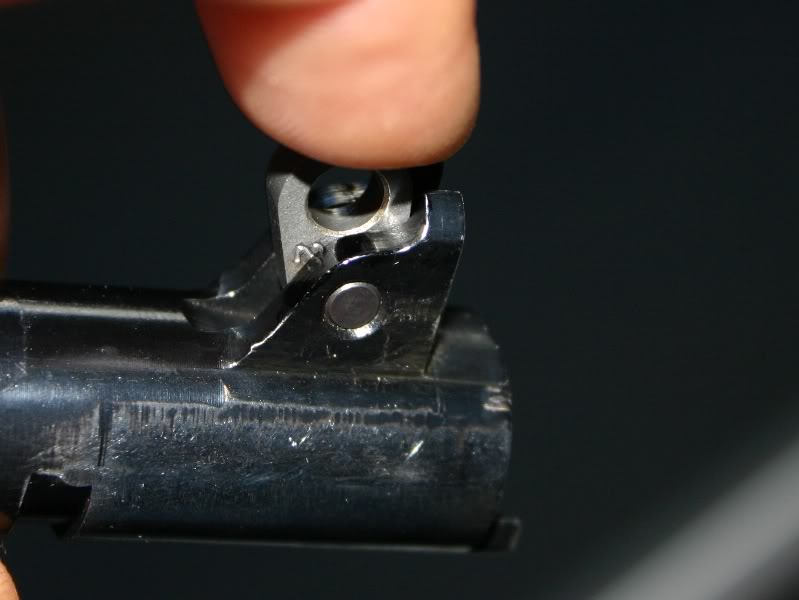

Here are some pictures of a week old Colt barrel that confirm the changes to the barrel knees.

I just installed a .273 link to allow the pin to contact the knees better. There seems to be more vertical lift caming on the new profile compared to the original profile. I intend to test the pistol this weekend.

Here are more pictures to evaluate the profile.

Niemi's layout on picture

Approximate initial pin contact.

Midway

Full up

Quote:

I just installed a .273 link to allow the pin to contact the knees

better.

Whoa! If that Colt barrel is a Gov't Model or "drop in" barrel needing no fitting, don't shoot the gun with the .273 link installed!!

Putting a shorter link on such a barrel - solely for the sake of getting the lugs down onto the SS pin - does nothing but reduce locking lug vertical engagement. If the original link was a 278, the reduction will be almost 0.005". The minimum locking lug vertical engagement is advertised as being 0.040" and that's what a mid-spec 1911 with a GI barrel has. Your 273 link will reduce that to about 0.035" and that's insufficient.

All Gov't Model 1911's ride the link all the way into battery and when in battery the barrel is supported by the link. The only proper way to get them so the SS pin supports the feet in battery is to fit a new barrel with oversized lugs that are cut down to provide maximum vertical locking lug engagement with the feet on the SS pin.

And there's really nothing wrong with a 1911 that rides the link all the way into battery. That's how they were all made. That's how JMB designed it. That's part of being a Gov't Model!

So put the original (278?) link back in before shooting it - with the feet maybe 0.009" off the SS pin. Won't hurt a thing and will work as designed.

Quote:

Putting a shorter link on such a barrel - solely for the sake of getting the

lugs down onto the SS pin - does nothing but reduce locking lug vertical

engagement.

Yes, I installed the 273 for more barrel control because the original 278 held the pin off the legs until the end of the cam-up cycle.

I measure .045+ vertical engagement with the both the 278 and 273 link.

Quote:

So put the original (278?) link back in before shooting it - with the feet

maybe 0.009" off the SS pin. Won't hurt a thing and will work as designed.

Yes, the original pin was 278.

But the SS-pin is still smaller than the link hole? My SS-pin measures .2005 with the link at nominal .2045.

At some point in cam up the link should give up control of the barrel to the SS-pin and barrel legs. There are witness marks on the barrel feet that show where the pin contacted the legs with the 278 pin.

I measure no difference in vertical engagement between the 278 and 273 pin only because the 278 pin allows the SS-pin to contact (control) the leg later in the cam-up action whereas the 273 allows the SS-pin to contact (control) the legs earlier in the cam-up. Both lock-up the same and stop the slide in the position.

There is noticeably more barrel control with the 273 link.

What happened to the idea that best link is alway the shortest link that still works?

Quote:

I measure .045+ vertical engagement with the both the 278 and 273 link.

That means the original barrel was being vertically supported in battery by SS pin/feet contact - and not the link. Notice the "If" after the "Whoa!" in my previous post. It wasn't, so disregard the rest of the post.

The rest was based on the premise the 278 link held the feet off the pin.

Oh well...

P.S.: Does the new shorter link still allow the barrel to hit the VIS before the bed when linking down?

Quote:

P.S.: Does the new shorter link still allow the barrel to hit the VIS

before the bed when linking down?

I forgot to check this... thank you... I just looked at the barrel in the bed and there looks like there is more than 1/32 gap between the ramp and the barrel.

Perhaps the 278 pin was just fine?

Just for giggles... try a little somethin' for me. There's still a few little things about the gun that aren't clearly understood.

With the link removed, check the vertical lug engagement by letting the slide snap into battery from about halfway back. If it's adequate... and I suspect that it is... use the .278 link and modify it to stop it from standing on the link by elongating the hole at the top... in the area closest to the lug when the link is in the in-battery position. That way, you don't alter the linkdown timing or have the barrel stopping on the link.

You'll probably be able to push down on the barrel hood and see the barrel drop slightly... but when the gun goes to battery, the lug's rear radius will climb the slidestop pin and provide good vertical engagement. (It's designed to do that. That's why it does it in some pistols.) It can't drop when the gun fires because of the pressure lock achieved between barrel and slide lugs... so you lose nothing in modifying the link to relieve the ride, and feeding will be smoother. Standing on the link to achieve a tighter... "lockup" doesn't help accuracy, and often hurts it. At the worst, you'll get a bit of vertical stringing. Inside of 25 yards, it won't likely make any practical difference, and it'll more than make up for the horizontal stringing that you'll get by standing the barrel on the link.

If you don't have adequate vertical lug engagement, you can get a little more by standing the barrel on the link, but you'll also place the link and its pin under stress that'll wallow out the hole, and allow the pin to fall out when the gun is field-stripped, and the gun will print low due to more upward barrel angle at the rear with the longer link.

The issues of the barrel dropping a few thousandths when pushed down aren't really critical, except for those who are chasing bughole groups at unrealistic distances during slow-fire target shooting. Much ado about nothing.

If the barrel drops .005 inch, it means a maximum dispersion of 3/4 inch due to inconsistent barrel return. That's the maximum dispersion for the two worst shots that can be attributed to the barrel fit... Maximum. I can barely see 3/4 inch at 25 yards... much less hit it with any consistency... even with a pistol that'll shoot 3/4 inch groups at that distance.

Relieve the hole in the link just enough to let the lug ride on the slidestop pin lightly as the barrel moves forward and up.

Quote:

I forgot to check this... thank you... I just looked at the barrel in the

bed and there looks like there is more than 1/32 gap between the ramp and the

barrel.

I don't think it's possible to determine if the barrel hits the VIS first during linkdown by looking at the gap between the barrel ramp and frame ramp.

Only way I know how to check it is do the timing tests from Schuemann Barrels via the link in our Tech Issues section.

Quote:

I don't think it's possible to determine if the barrel hits the VIS first

during linkdown by looking at the gap between the barrel ramp and frame

ramp.

Sure ya can. Gun assembled... slidestop pin through the link... arm hanging vertically. Push back hard on the muzzle and see if the slidestop swings easily. If it does it's not stopping on the link. If it doesn't swing freely, but is only in a slight bind... Check for bed contact by painting the bed and lower barrel radius with a Sharpie marker or layout fluid. Assemble the gun without the recoil system. Smack the muzzle 4 or 5 times with a plastic mallet... pushing the slide back into battery each time... and look for bare spots in the ink. If they're there... the barrel is hitting the bed before it hits the VIS... or it's hitting it at the same time and placing the link in a bind. Bad JuJu either way.

If the slidestop swings completely free... the barrel is stopping on the VIS and it isn't hitting the bed.

Quote:

With the link removed, check the vertical lug engagement by letting the slide

snap into battery from about halfway back. If it's adequate...and I suspect

that it is...use the .278 link and modify it to stop it from standing on the

link by elongating the hole at the top

OK thank you....I just measured .040 engagement or .005 less than what I was avgeraging with both links

Quote:

If you don't have adequate vertical lug engagement, you can get a little

more by standing the barrel on the link

I appears that I have adequate engagement.

Quote:

I don't think it's possible to determine if the barrel hits the VIS first

during linkdown by looking at the gap between the barrel ramp and frame

ramp.

Thank you... I have both KuhnHausen books and have read though the tech issues section but didn't find the Schuemann test....there is a lot of into to digest...

There is a .005-ish gap at linkdown. I visually gage that there is more that a sheet of paper thickness (.003") clearance between the slide the top of the barrel when the barrel drops.

And, as if you didn't already have enough info to digest, here's the Schuemann timing test instructions: http://www.m1911.org/testkit.htm

What exactly are "bad JuJu" issues if the SS pin drags. I have two home builts with slight drag and a Les Baer PII with heavy drag.

Love your drawings, they're a tremendous help.

Dirty guns tell stories. Every time you clean the gun you have the oportunity to tell where the barrel is hitting, what's hitting on the extractor, and any other things hitting in places that they shouldn't be. Sharp edges gouging, and so on.

For a specific problem, the Sharpie and a soft mallet are your friends.

There's some good fitting info on Schuemanns web site too.

But personally me thinks this whole thing is being over analyzed. It's not that hard to get the 1911 to run properly.

Quote:

What exactly are "bad JuJu" issues if the SS pin drags.

When the slide is back about 1/4 inch and the back end of the barrel is forced aft and down, the back of the barrel lugs should be against the VIS and the bottom of the barrel should be on the barrel bed in the frame - with the link loose - making the slide stop (hanging down over the trigger guard) free to swing back & forth.

If the link it not loose (is still in tension or compression) the slide stop will not be loose (free to swing) and that means one of two things - both bad: * The barrel will hit the bed first during linkdown and will never contact the VIS, keeping the link in tension. This will eventually break the link. [Edited: or even worse... see next post]

* The barrel will hit the VIS first (like it should) to relieve tension in the link, but the barrel does not fall all the way down to the bed because it's kept off the bed by the link. This puts the link into compression. While this doesn't hurt the link, it reduces the clearance between the top of the barrel and the underside of the slide. [Edited: By creating a gap between the barrel & bed, it also creates a place where the bullet can catch and lift the barrel during feeding and cause jams - if the gap is big enough]

Quote:

What exactly are "bad JuJu" issues if the SS pin drags. I have two home

builts with slight drag and a Les Baer PII with heavy drag.

In addition to what niemi posted... If the barrel is stopped by the link instead of the VIS... or if it hits the bed first...i t can pull the lower lug off the barrel, sometimes clear through to the chamber.

Quote:

But personally me thinks this whole thing is being over analyzed. It's not

that hard to get the 1911 to run properly.

Agreed. This thing ain't exactly a Swiss watch.

Quote:

...use the .278 link and modify it to stop it from standing on the link by

elongating the hole at the top...in the area closest to the lug when the link

is in the in-battery position. That way, you don't alter the linkdown timing

or have the barrel stopping on the link.

I just eggshaped the upper .278 link hole.