Found this video today from Jack Weigand:

Colt_1911_Barrel_Fitting_Hood_Fitting_Part_1.flv

Now I got a "C" in shop class so I'm not the sharpest file in the tool chest, but can someone tell me why he took almost all the material off the right side of the hood instead of filing both sides evenly?

Disclaimer: The following is from a non-machinist and non-gunsmith.

The video seems to begin with a barrel with a 0.450" wide hood previously properly oriented (by the ports?) in a slide with a 0.443" recess. The difference between the first two measurements (0.449" with the height gage and 0.443" with the gage pin) showed the right side of the hood overlapped that side of the recess by 0.006", so 0.006" was milled off the right side of the hood.

After the right side of the hood was cut, the remaining hood width (0.444" found with the calipers) was 0.001" too wide for the previously measured 0.443" recess, so 0.001" was milled off the left side of the hood.

Taking half the hood's excess width off each side only works if the overlaps are equal with the barrel properly oriented. If that's not the case, doing so will end up having the barrel twisted in the slide.

Hello and than you for sharing the video, (same disclaimer for me too)

I found it interesting that he didn't mention the barrel guide blocks. I am currently of the opinion (please correct me if I'm wrong) that for accurizing a 1911 the barrel hood should contact the slide's breechface to push the barrel into battery not the guide blocks. His hood fitting didn't mention breechface contact and only mention headspace. Nor did it mention barrel end play to avoid slap-seating the barrel/slide lugs.....I know Jack Weigand is very good at what he does so I must misunderstand something?

Toward the end of the video he says he used an "EGW hood length gauge" - whatever that is - to determine the hood was 0.002" too long and was preventing the barrel form going all the way up into the slide. He then shortened the hood by 0.002' and got it to go.

Doesn't that mean the barrel has no fore-aft play in the slide?

Quote:

Doesn't that mean the barrel has no fore-aft play in the slide?

IMHO 1911 builders are truly artists which means there is no "one way" to strive for perfection.

I'm sure the pistol he is building will shoot fine and perhaps there are many small details he didn't include the short video... I misunderstood the EWG hood gage as a headspace go-no-go gage.

Quote:

...the EWG hood gage...

...looks (if the pic is enlarged) http://egw- guns.com/store/index.php... &products_id=50 like it measures the distance between the breechface and the #1 lug face in the slide in 0.002" or 0.003" increments. Interesting gizmo.

Quote:

Taking half the hood's excess width off each side only works if the

overlaps are equal with the barrel properly oriented. If that's not the case,

doing so will end up having the barrel twisted in the slide.

That part I understand. What I didn't follow was how he arrived at the .006 being all on that side. Why not .004 and .002? How did they arrive at the proper orientation to measure to the thousandth of an inch?

Quote:

...how he arrived at the .006 being all on that side.

The barrel was probably oriented from side-to-side and rotationally within the slide by using a fixture that gets the lower lugs exactly in between the slide rails and aligns them with the slide's axis. At that point, the back of the hood is just at the recess's entry.

The subsequent measurements show the hood won't enter the recess beause it's 0.006" too wide on its right side and 0.001" too wide on its left side.

He found 0.006" needed to come off the right hand side of the hood because with the barrel centered in the slide, the right side of the hood was 0.006" above (above, as seen in the video) the right side of the recess. And using the left side of the recess as the zero reference point the right side of the hood was 0.449" above it. By subracting the width of the recess (0.443") he found how far the right side of the hood was above the right side of the recess, or 0.449 - 0.443 = 0.006".

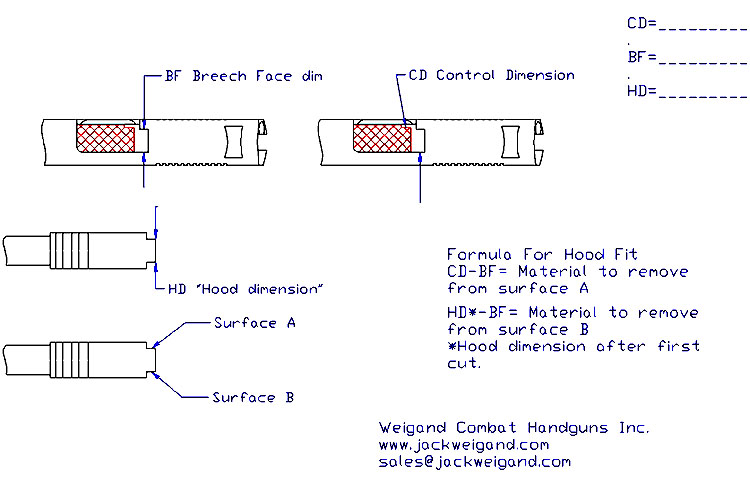

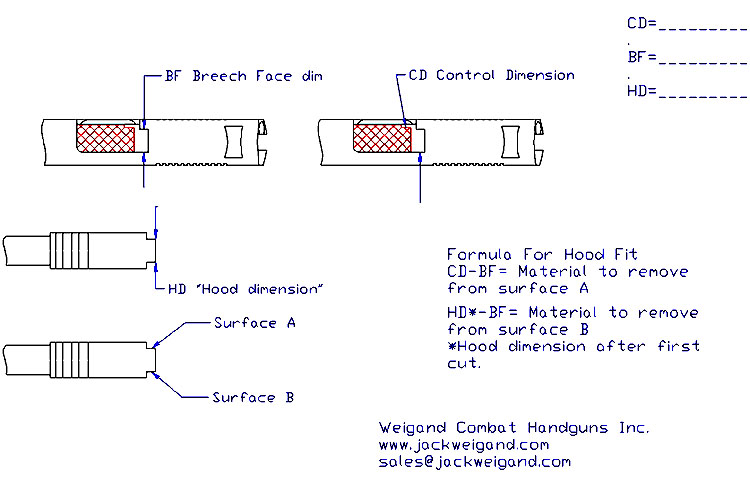

Maybe this'll help:

PICTURE 404

I found this worksheet on Jack Weigand's web site and since the actual image resides on his web server I don't think (it gets me into trouble) that there is a copywrite problem.

Quote:

The barrel was probably oriented from side-to-side and rotationally within

the slide by using a fixture that gets the lower lugs exactly in between the

slide rails and aligns them with the slide's axis.

Ah OK. That mostly answers my question. I was concerned that if one didn't have the barrel exactly square in the slide the measurements would be off.

Found it on Brownells -

I use the barrel alignment block, but it must be fit to the width of the lower lugs. As the block comes narrow, and needs to be fit to that area of the barrel to be used.

In the video, it appears he uses the frame to align the barrel for the slide measurement.

Either that or the frame's just used to hold everything for the measurements and the barrel's more closely aligned in the slide by the compensator port block (or whatever that thing is called). Looks like it fits into the slide without too much side-to-side wiggle room. Anyway, I didn't even notice the frame until you mentioned it. That eliminates the little barrel alignment block - in the video, at least.

Q: Do shims need to be used with the alignment block to take up any play between the block & slide and the block & barrel (or does the block align it all close enough without getting that fancy)? [Edited: How could I possibly miss that in a 1 line post? Don't answer that!]