I inherited the pistol from my grandfather. When I initially inspected the pistol I found that the barrel was completely shot out, shallow riffling with heavy pitting. I ended up purchasing a like new Colt barrel from a forum member. I dropped the barrel in and tested for fit. By the way, I have fired the pistol with the like new Colt barrel installed and it's accurate and has no other problems with the barrel except for its vertical lock up.

If I press my finger on the barrel hood (pistol in battery) I get downward movement on the barrel. I measured the downward movement of the barrel at .014". When I release pressure on the hood the barrel moves up to its original position.

Any idea on what's going on here? Any idea on what the proper fix is?

Does barrel do the same thing when the recoil spring is removed?

Yes it does. However, it does not return to its original or most tallest position since there is no spring tension on the barrel from the recoil spring being removed.

quote:

Q: Do you see any evidence of contact between the recoil spring guide and

the bottom of the barrel, the lower barrel lugs or the link?

The 0.014" of downward barrel movement is near the upper limit of the normal range of travel for a Gov't Model M1911A1, but the barrel moving back up is not normal. The fact that the barrel did not go back up when the recoil spring was removed indicates the barrel is being moved up either by the recoil spring acting on the bushing or the recoil spring guide. But spring/bushing action would make the back of the barrel go down, so there must be some contact between the spring guide and the bottom of the barrel, the lower barrel lugs or the link.

quote:

Q: Do you see any evidence of contact between the recoil spring guide and

the bottom of the barrel, the lower barrel lugs or the link?

I looked at the recoil spring guide and tried to look for any contact marks between it and the barrel, lower barrel lugs or the link. I could not find any evidence of contact between these parts.

Well I'm stumped. As BigJon said, it's normal for a Gov't Model barrel to ride the link into battery. If the gun is put slowly into battery, the link will be in light compression due to just the influence of gravity and cannot be made to go any farther down.

Even if the gun is slowly put in battery when upside down (with the link in light tension), when the gun's put upright and the barrel pushed down - it should stay down.

Spring guide contact is the only thing I can think of that would cause the barrel to go back up after being pushed down (unless your gun's haunted!).

What about the barrel bushing relief? If it's not setup correctly, could it be putting the barrel in tension causing the barrel to spring back up?

Quote:

I could not find any evidence of contact between these parts.

Maybe there haven't been sufficient cycles to create a wear mark. Try coating the areas that might contact with a magic marker, cycle it & push down the barrel a bunch of times and see if the ink gets rubbed off anywhere.

I think you could even shoot it a bunch - don't see where any harm would be done.

Quote:

What about the barrel bushing relief? If it's not setup correctly, could it

be putting the barrel in tension causing the barrel to spring back up?

Possible, I suppose, but if that was the problem I'd think it would keep the barrel from falling all the way down to the bed when the slide's back. Hmmm-m- m...

Since the slide is under spring tension, it's probably the slide that pushes the barrel forward, when you release the pressure and as it pushes it forward, it also pushes it up, due to the link action.

I looked at the barrel/bushing and all appears fine.

How do I correct this problem of vertical lock up?

Does the gun have a "Group Gripper" installed?

No Group Gripper installed.

Good, no group gripper.

Here's Post #9, in case you missed it:

Quote:

Maybe there haven't been sufficient cycles to create a wear mark. Try

coating the areas that might contact with a magic marker, cycle it & push down

the barrel a bunch of times and see if the ink gets rubbed off anywhere.

I think you could even shoot it a bunch - don't see where any harm would be done.

quote:

"Q: Any ink get rubbed off?"

I have not tried as suggested yet. However, what would it matter where the spring pressure is coming from? I do think John is correct in his assessment of the spring tension.

Again, how can I resolve this problem, not with the spring tension, but the issue about the lock up? Does the barrel need to be fitted, or a longer link installed?

By the way, I installed this barrel about 500 rounds ago. The pistol runs flawless. This lock up issue existed as soon as I put the new barrel in. I have now just got around to addressing the problem.

Quote:

I have not tried as suggested yet.

Please inform us of your findings when you perform this test.

Quote:

However, what would it matter where the spring pressure is coming from?

Because the recoil spring does not ever directly contact the barrel if the gun is working properly. It contacts the barrel indirectly only through the slide. The recoil spring drives the slide forward towards battery and the slide then pushes the barrel forward towards battery.

The recoil spring does not directly drive the barrel upward into battery. The barrel is driven up into battery only indirectly by the recoil spring because as the slide drives the barrel forward, the link lifts the barrel up.

Once battery is reached the recoil spring holds the slide against the barrel and the barrel stops the forward motion of the slide by its contact with the slide stop pin. Once in battery, the recoil spring does not hold the barrel up - the link does, in a Gov't Model.

From your description and my understanding of it, your barrel in battery is being spring-loaded into the upward position because when you push down on it it goes down 0.014" and when you quit pushing the barrel goes back up.

The barrel should NOT be spring-loaded into the upward position and correction of the "problem" is contingent upon finding exactly how the recoil spring is spring-loading the barrel into the upward position. Unless the recoil spring has a severe kink that always gets installed "up", the only way I can see how the recoil spring can spring-load the barrel into the upward position is if the guide makes contact with the barrel's bottom surface, lower lugs or the link.

Quote:

I do think John is correct in his assessment of the spring tension.

John is correct. He described how the recoil spring gets the slide and barrel into battery.

Quote:

Again, how can I resolve this problem, not with the spring tension, but the

issue about the lock up?

You can resolve this "problem" by:

* Correcting any misunderstanding I may have about your description. If there is no misunderstanding...

* ...help us figure out how the barrel is being spring-loaded into the upward position after it is in battery by digging out your magic marker.

P.S.: FYI, the average Gov't Model will have about 0.040" of vertical locking lug engagement in battery (link in compression) but a maximum amount of about 0.060" with the link removed and the barrel fully up into the slide.

Quote:

Q: Does the barrel fall all the way down to the bed when the slide's

back?

And this would be with the gun fully assembled.

It really isn't a problem, just the difference of how the barrel is fit. Few production guns lock up on the slide stop pin as preferred due to the need to individually fit the barrel to the slide and frame.

I don't think it's a problem either, except at this point I'm not really sure what the condition is that Rocket 6R considers a problem. Not sure if it's:

* Insufficient locking lug engagement,

* Being able to push barrel downward when in battery,

* Barrel popping back up after being pushed down in battery,

* Some combination of these, or...

* Something else entirely that my little noggin just doesn't grasp.

Could it be something as simple as he thinks a Gov't Model's barrel should lock up tight in battery - and can't be pushed down?

I did a simple test! I took out the recoil plunger, which relieves spring tension (recoil spring is now at rest full expanded). I no longer have the barrel springing back up into its original position.

After coating the suspected parts with a black marker and cycling the pistol I found two small contact marks under the barrel and forward of the link. It appears that the recoil plunger guide is making contact with the barrel when I press the barrel down while in battery. The ends of the horseshoe on the recoil plunger guide are making the marks.

Great! But before doing anything we need to consider that while this contact is abnormal, it would seem to provide a little more vertical locking lug engagement - maybe 0.014" more.

There's no Group Gripper installed in the gun, but for some reason the spring guide is acting like one. And more vertical engagement is always a good thing as long as linkdown timing is not compromised. And I don't see how this "accidental group gripper" could possibly compromise linkdown timing.

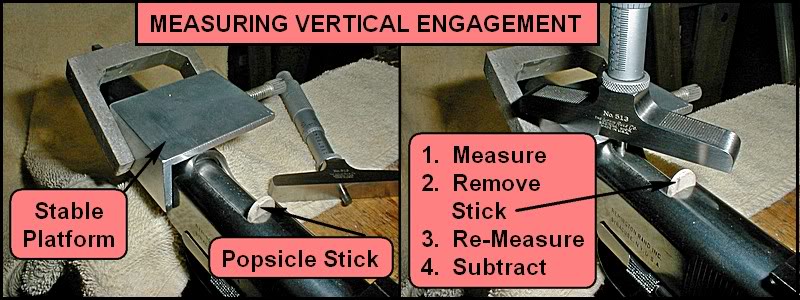

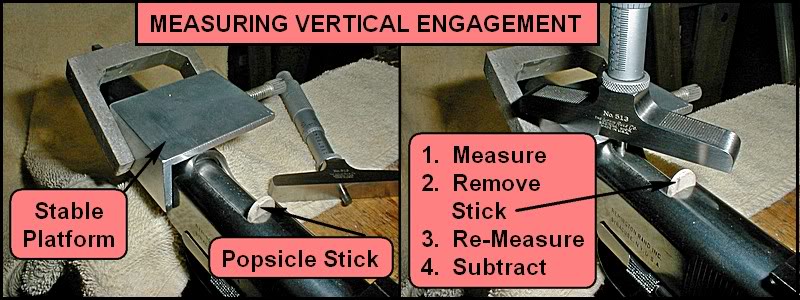

Just for grins, put the gun all together and see how much vertical locking lug engagement the gun has using this or a similar method:

What I'm thinking here is that it may be to your advantage to leave the gun just like it is. Just as a wild guess, you may have more than 0.050" of engagement.

I took some measurements per your request.

I measured from the top of the slide to the top of the chamber. Chamber area was measured closest to the front of the pistol.

Popsicle stick inserted between the breach face and barrel hood.

.172"

Popsicle stick removed.

.125"

difference of .047"

Popsicle stick removed and me pressing down on the barrel.

.136"

With the gun like it now is your engagement is 0.007" above average - and that's good.

But if you eliminate (with a file) the contact between the guide's horseshoe shaped flange and the barrel (so the barrel won't move back up after being pushed down) it looks like you might end up with as little as 0.173 - 0.136 = 0.036" of engagement. That's about 0.004" below average, but it all depends on where the barrel actually ends up vertically when in battery.

I'm inclined to say leave it like is and shoot it as long as the linkdown timing is OK (barrel hits VIS first - then drops down to the bed).

Still sounds to me like there's some barrel springing going on. i.e.-barrel bushing as no relief at frt. lower edge & rear upper edge. The barrel tilts when locking up & bushing doesn't want to let it happen??

Quote:

Still sounds to me like there's some barrel springing going on. i.e.-barrel

bushing as no relief at frt. lower edge & rear upper edge. The barrel tilts

when locking up & bushing doesn't want to let it happen?

Not following this as the OP says that if the barrel at battery is pushed down it comes back up. So how would a too tight bushing allow this to happen?

Quote:

Still sounds to me like there's some barrel springing going on. i.e.-barrel

bushing as no relief at frt. lower edge & rear upper edge. The barrel tilts

when locking up & bushing doesn't want to let it happen?

Springing? Why doesn't it happen with the recoil spring removed?

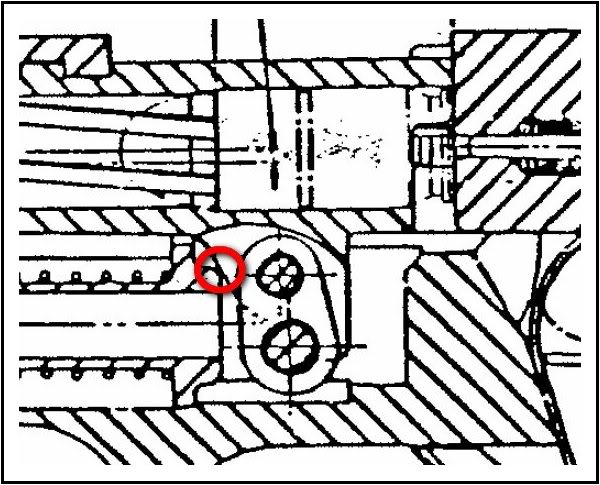

My guess about what's going on in this gun is that there's contact between the barrel's lower lugs and the guide rod when the gun's in battery...

...and this contact does three things: it lifts the back of the barrel up a little bit; it pushes the guide rod forward a little bit; it tips the front of the guide rod down a little bit, putting a slight kink in the recoil spring.

When the OP pushes down on the back of the barrel, the barrel goes down a little bit until the link goes into compression, the front of the guide rod goes back up, but the guide rod flange does not go back against its abutment in the frame. When the OP releases his downward pressure on the barrel the front of the guide rod moves back down and the lower lugs cam the barrel back up because of the contact at the area circled in red.

Howzabout that for a wild guess? Might be the best zebra I've had all year!

Rocket... Without seein' the gun, I'm gonna bet that when you let it snap to battery, and push down on the barrel...the slide creeps back about a 64th inch. Then, when you let go of the barrel, the slide moves forward again to the normal position.

Link too long? I'm lost!

Quote:

Link too long?

Nope.

I'll toss out a few clews. Then I'm goin' to bed. Been a long time since 0400.

It's fairly common in ordnance spec guns. It's not a major issue. About the only problem it'll cause is vertically strung groups that probably won't even be noticeable until the distance gets up to about 25 yards and only if the shooter is a good marksman.

Just don't push down on the barrel before you fire it, and it'll be okay.

It's not the link and it's not the bushing. The barrel isn't springing and the guide flange isn't levering the barrel up.

Quote:

Rocket... Without seein' the gun, I'm gonna bet that when you let it snap

to battery, and push down on the barrel... the slide creeps back about a 64th

inch. Then, when you let go of the barrel, the slide moves forward again to

the normal position.

Tuner, I was wondering where you were at!

I tested the pistol, per your suggestion. The slide does move to the rear slightly. Granted, I did not measure the rearward travel of the slide, but I would say that it was only a few thousands of an inch.

As the barrel tilts down it creates a longer angle against the breach face which causes the slide to move to the rear.

Try this:

The lower lugs are cut in an 'S' shape. In a theoretical, ideal pistol the barrel both rest (vertically) with the horizontal portion of the lug sitting directly on the slide stop pin, and the barrel is stopped from going farther forward by the vertical portion of the lug contacting the slide stop pin. In order for this to occur, there would have to be 90 degrees of contact between the lug and the pin. (Viewed from the left side of the pistol using your x-ray vision, contact from 12:00 to 3:00.)

But this is a drop-in barrel, not hard fitted. The barrel is riding the lug, which means when forward motion stops the slide stop pin has NOT made contact with the underside of the lug. Depending on just where the pin contacts the lug, when the barrel is pressed down the slide stop pin may be sliding up the vertical portion of the lug into the curved portion, and as the top of the pin slides along that arc the barrel is pushed slightly rearward as it moves down. Rearward, of course, is against the recoil spring, so when the pressure is released, the recoil spring pushes the slide forward again, and the barrel reacts accordingly.

If the problem lies with the new barrel, it's either that the lower lug corner radius is too large (larger than the slide stop pin radius)....

...or that the "vertical" part isn't at 90deg to the barrel axis?

So, if this is the true nature of the problem wouldn't it be beneficial to

have the lower lug radius oversized as depicted in the picture? Meaning, the

spring action allows the barrel to stay in its most upright position, which

would allow for greater lug engagement.

Quote:

At first glance it sure seems like a good idea, doesn't it? Almost like it's

too good to be true. Gun's been around for 100 years, so why aren't they made

this way? How come nobody thought of this before?

Maybe somebody did think of this before and the idea was discarded because of

some drawback we haven't thought of.

But what could that drawback be (if there is one)?

Quote:

As the gun dirties up, the POI changes? If something sticks, it appears to go

into battery, but engagement is less than it should be?

Hawk gets the kewpie doll.

The lower lug radius is climbing the slidestop pin and forcing the barrel up.

Because the pin isn't solidly supporting the barrel, it can be pushed back

down... but won't drop on its own. Upper lug engagement is good, so the lugs

won't be damaged when the gun is fired. Just don't push it down before you

fire it, because although it'll move back up when the slide moves back

forward, it won't move up as far as when the slide goes home at full speed.

About the only issue is a little vertical stringing that won't amount to a

hill of beans unless 50 yard Bullseye is your game because it won't

consistently return to the same position between shots... but the difference

will be negligible.

Heh, I was correct in that the barrel moves the slide back when pushed down,

I just didn't explain why! Darn, I failed the class again.

Rocket 6R

16th October 2010

niemi24s

16th October 2010

So, if this is the true nature of the problem wouldn't it be beneficial to

have the lower lug radius oversized as depicted in the picture? Meaning, the

spring action allows the barrel to stay in its most upright position, which

would allow for greater lug engagement.

RobL

16th October 2010

But what could that drawback be (if there is one)?

1911Tuner

16th October 2010

John

17th October 2010

Return to 1911 Archive