I just got a Nowlin Pre fit barrel for my latest build. Out of the package I noticed the front of the two lugs has quite a bit of radius cut on them instead of being square and the front lug looks to have a slight angle on it. I'd like to know if this is normal before I start to fit it.

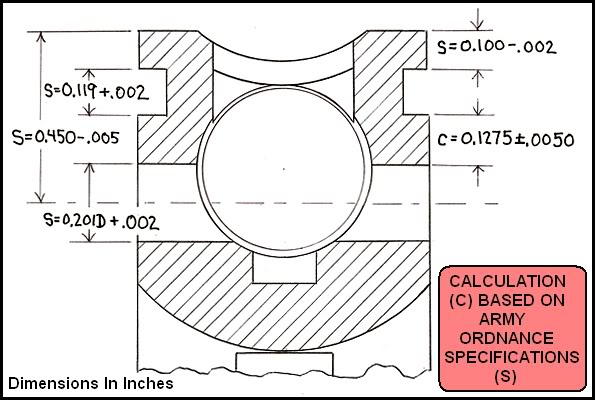

I have no idea what specifications Knowlin uses for their barrels, but the Army Ordnance specifications for the M1911A1 barrel are available in our Tech Issues section, 14th link down from the top.

The Nowlin barrels were designed by John Nowlin Senior to lock up at .042" at 12:00 on the top of the barrel. Measure the depth of the first upper lug it should measure .042" in depth. As "a drop in" or pre-fit the sides of the radii should already be adjusted for clearance. If it is a gunsmith's barrel the first lug is usually at .038" and will have to be fitted to .042" as well as the rest of the barrel fitted to your existing slide. Bar Sto does a similar barrel in their marine cut in which the first lug is fitted for 100% contact on the first lug at .042" in depth.

Quote:

...the first lug is fitted for 100% contact on the first lug at .042" in

depth.

With the first lug on the slide being (on average) 0.061" deep, I'm assuming your 100% is referring to full barrel lug contact - and not to % of engagement between the lugs, which is about 69%?

At least 0.061" is what the Ordnance blueprint tells me. And that's about what Petunia's Remington Rand slide measures. No idea how the various slide makers turn them out nowadays. Are they less than 0.061" nowadays?

In a match barrel the first lug recess is cut more shallow than 2 and 3. The slide is the same.

Quote:

In a match barrel the first lug recess is cut more shallow than 2 and

3.

Is that done just because 0.042" of engagement is adequate or to prevent long- linking for more engagement and possibly running into linkdown timing problems?

Or maybe to strengthen lugs 2 and 3 by making their cuts shallower too?

Quote:

Is that done just because 0.042" of engagement is adequate or to prevent

long-linking for more engagement and possibly running into linkdown timing

problems?

Or maybe to strengthen lugs 2 and 3 by making their cuts shallower too?

It's pretty close to a std. link#3 .278", 2 and 3 are cut the same as before. It provides a tight lock up between the slide stop pin and slide, and functions in the designed way without extreme measures. How much engagement do you see in a mil spec?

Quote:

How much engagement do you see in a mil spec?

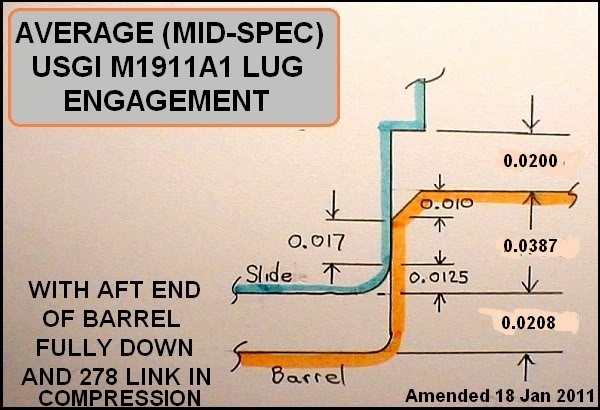

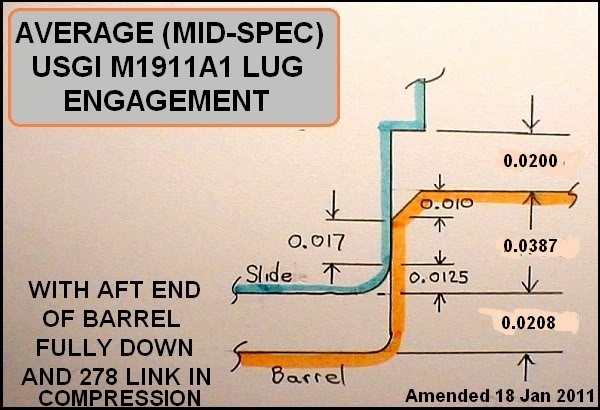

Here's what I came up with after a few days with the blueprints a few years ago:

It was the lengthiest series of calculations I'd ever done on the 1911. Tuner, I think it was, had mentioned 0.040" at one time. That 0.0395" is with the slide all the way down on the frame too.

Plus this is should be the most engagement at the highest point of the two non-concentric circles. The actual surface contact forms a crescent moon shape.

Yes, to the barrel engagement and Big John is correct.

Also, John Senior's logic the way he explained it to me, at his pistol class, was that a triangle was the most stable architectural structure. So 12:00 contact on top of the first lug and contact on the the slide stop pin on both lower feet at 12:00 and the rear of the slide stop pin at 3:00 create triangles which stabilize the rear lock up.

In this way there is very little wear on the sides of the barrel at 10:00 & 2:00 which would allow the rear of the barrel to move higher in the slide lugs over time (two different concentric circles the barrel being the smaller of the two) with use and possibly creating feeding problems and change in POI/POA in the future. In his mind, the way I perceived it, just less potential future problems by addressing it in the installation.

Also, John had his own frames manufactured to his specs. By keeping things in the middle of the operational envelope it enabled him to custom assemble pistols with a minimum of fitting and a maximum of accuracy by being able to measure the vertical height of the frame and barrel and slide engagement.

This all comes back to Big Johns .278", #3 lug, which is in the middle of the vertical height specs that the 1911 seems to time and work best at. For example, the distance from the top of the slide stop pin hole on His frames to the bottom of the first frame rail was usually .125".

Most Springfield Armory 1911s will vary up to .135" which is 2+ link sizes higher. Don't take that statement wrong...the pistol will run fine with a #5 link however, if you can set one up for a # 3, the longevity of the pistol is increased or enhanced for future barrel changes.

John was way ahead of his time when it came to standardization for better quality which I believed came from a Aerospace engineering degree or background.

I hope that the above explanation answered your questions adequately.

Quote:

I hope that the above explanation answered your questions adequately.

Yes it did, thank you, except for two things:

* Is the top of the pin hole to the bottom of the first frame rail distance you referred to the 0.1275" one shown here?

* When you said most Springfield Armory frames will vary there up to 0.135", is that today's civilian Springfield Armory, or the old Army Ordnance one?

Talked to the Tech guy at Brownells. The ones they have in stock don't look like this one. New one is being overnighted to me all on Brownells dime. Awesome customer service!

Yes it is that measurement and the Springfield Armory measurement was on the civilian model.

Just for "Sh&ts & Giggles" I measured a Foster/Caspian frame that just came in and it measured .135."

...Without getting into too much philosophy... if you know your vertical specifications you can measure your frame and barrel and mathematically determine a link size. Once you install the barrel if you have too you can go up a link size if necessary for better timing and go up in slide stop pin size to compensate for the bottom barrel lock up, if necessary.

Quote:

I measured a Foster/Caspian frame that just came in and it measured

.135."

Hmm-m-m. Wonder if the extra 0.007" to 0.008" there is obtained:

* by having the SS pin holes that much farther down from the top of the frame, or

* by reducing the rail and/or way heights that much?

If it's the first one, the distance from the top of the SS pin hole to the top of the frame on that Caspian should be about 0.354".

I won't be able to give you the second measurement till tomorrow since the frame is at my office and I cannot access it till then.

Duh! Must be that the pin hole is lower based on what you said about it needing a longer link. Now why didn't I figure that out earlier?

Ok Dude... the measurement is .220"+.135=.355" and if you consider that the calipers I am using have a flat edge which is measuring against a round hole take another .001" off you are at .354"... So, pat yourself on the back and if you can't quite reach it treat yourself to a chiropractic adjustment on your elbow...

Well, it was just a guess. But thinking more about it a little more the alternative of modifying the frame rail & way heights would probably mean Mr. Knowlin would need slides with matching custom rails & ways. Not sure if anybody would want to build a gun and make it that sort of a "one of a kind" - where no other slide would fit.

Well... John had his own slides manufactured and I can tell you his pistols were some of the finest running 1911s I've ever shot. And since Bill Wilson and John were close friends and John seemed to be the experimenter they came up with quite a combination. You also have to realize at that time Chip McCormick, Nowlin and Wilson used to get their frames and slides from Jericho which made their frames and slides to the custom smiths specs. When Kimber purchased Jericho they ended the custom smiths source for frames and slides with their "quirks" and were way ahead because they didn't have to experiment to get the benefit of the custom smiths work.

Of course they couldn't leave well enough alone and IMHO the Kimber quality is not the same as it used to be, especially when they came out of Clackamas. Since then McCormick has stopped selling frames and slides, Nowlin as well, and Wilson has had the benefit of all that knowledge. Mr. Wilson has used that knowledge admiringly well to produce a first class product and continues to do so.

Guess I spoke too soon about the custom slides. Thanks for the history lesson and the mention of Clackamas. I'd seen it used occasionally over the years on this forum and thought is was just a made-up name, kind of like Dogpatch. Googled it and lo & behold it's a real honest-to-goodness place!

Dudes! This isn't about any measurements or specs. The front of the two lugs are "round". Like somebody went nuts with a Dremel. Then the front lug looks like it's leaning back. The lug was a factory oops! The grinding of the front lugs was either done at the factory or somebody bought this barrel and after Dremeling the heck out of it, sent it back to Brownells. The bags were sealed.

Please send it back as that isn't right under any circumstances.