I build a home built custom last year and was fortunate enough to achieve three lug contact between the barrel and slide (mostly luck ). This was using a Kart Easy fit barrel.

Yesterday I just shot my 1800 round after chrome which is about 2200 after I install the barrel. While cleaning and inspecting the parts yesterday I noticed that the number one lug contact area isn't shaped like the contact areas of lugs two and three.

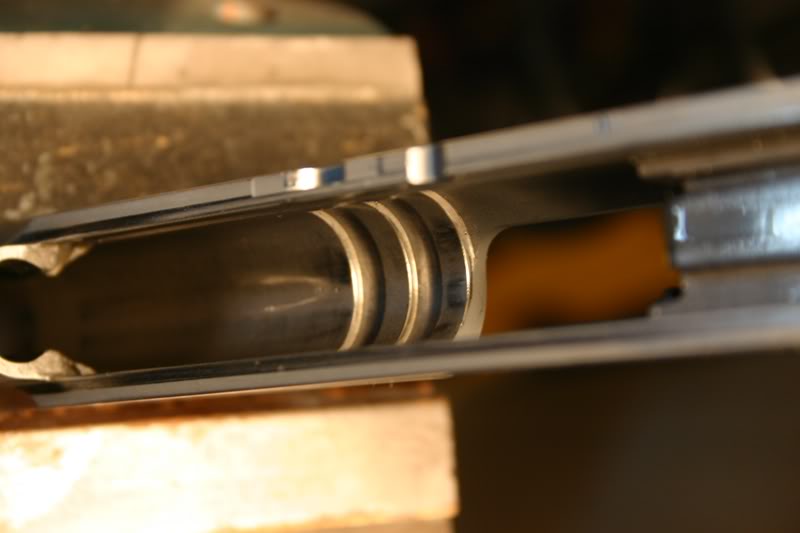

Here is a picture of the slide lugs:

Here is the lug to barrel contact areas: (yellow is shown bellow the contact areas)

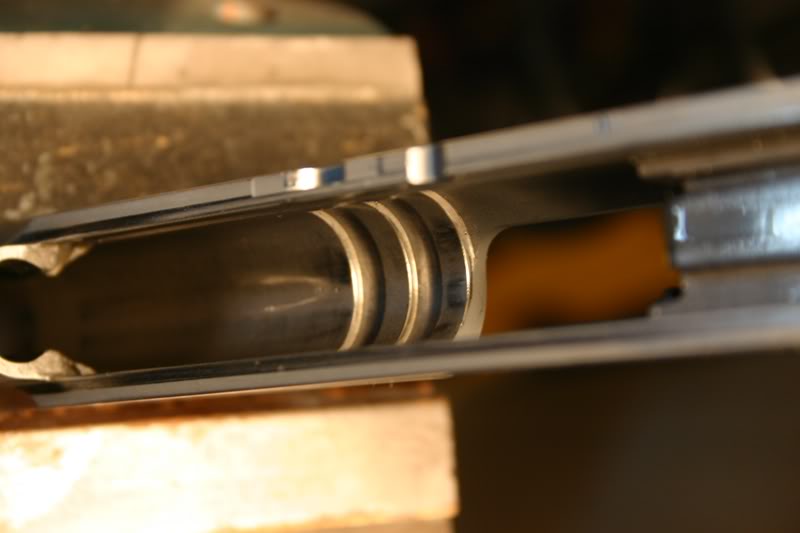

Here are some pictures that show that the number one lug contact is mostly to the left

Barrel in battery with full lug contact (91% of available vertical engagement)

Here is a link-down photo showing contact on the left side of the slide lug.

I find it interesting that most of the number one lug contact area in to the left of center of the slide.

I wonder if this is by design?

There is nothing in the Ordnance blueprints that indicates it's by design. Whatever contact there may be would be even from side to side, and not concentrated on one side. Maybe just something a tad off in the manufacture of the barrel and/or slide?

Or possibly more chrome got deposited in some areas than got deposited in other areas (if that's even possible)?

The lug contact marks you're seeing are from cycling not from in battery. Most often mention of lug contact is in regards to the lug recess faces.

So the marks are from link down when the lugs are pulled down out of battery?

The recoil spring should hold the barrel back at link-up... correct?

When I set-up the barrel I dychem blued the barrel lugs. Installed the barrel in the slide with the bushing. Then I whacked the back of the barrel knees with a rubber mallet to see how much lug contact there was when the barrel was horizontally forward (locked) in the slide.

I removed some material from the barrel lug faces until I got all three lugs to contact. The only drawback is that I ended up with 6-7 thou barrel movement / hood gap and a weird number one lug contact profile. I thought that it was a small price to pay to guarantee three lug contact.

Removing material from the barrel forward lug faces is fine, but should be done before hood fitting. The recoil spring only controls the slide. With the barrel tilted up at the chamber end 52' in battery the tops of the lugs can't touch, only when cycling. the marks on the are from the top of the barrel chamber area. Few 1911's have all three lug faces in contact with the slide, many only one. I do agree more is better, mostly for accuracy, more contact.

More:

Now that the barrel lugs are equalizing after 2000+ round I thought that the

contact area would become more uniform.

Quote:

Removing material from the barrel forward lug faces is fine, but should be

done before hood fitting. The recoil spring only controls the slide. With the

barrel tilted up at the chamber end 52' in battery the tops of the lugs can't

touch, only when cycling. the marks on the are from the top of the barrel

chamber area. Few 1911's have all three lug faces in contact with the slide,

many only one. I do agree more is better, mostly for accuracy, more

contact.

I tried and tried and tried to measure the barrel and slide to fit the lugs before I cut the hood but it didn't workout that way... there is nothing like experience huh...

I wanted three lug contact for durability. All of my other production 45s experience some type of wear/breakage around 3000 rounds for what ever the reason so I started a project determined to build a more durable 45. My Springfield and Colt both went back for warranty work around 3000 rounds.

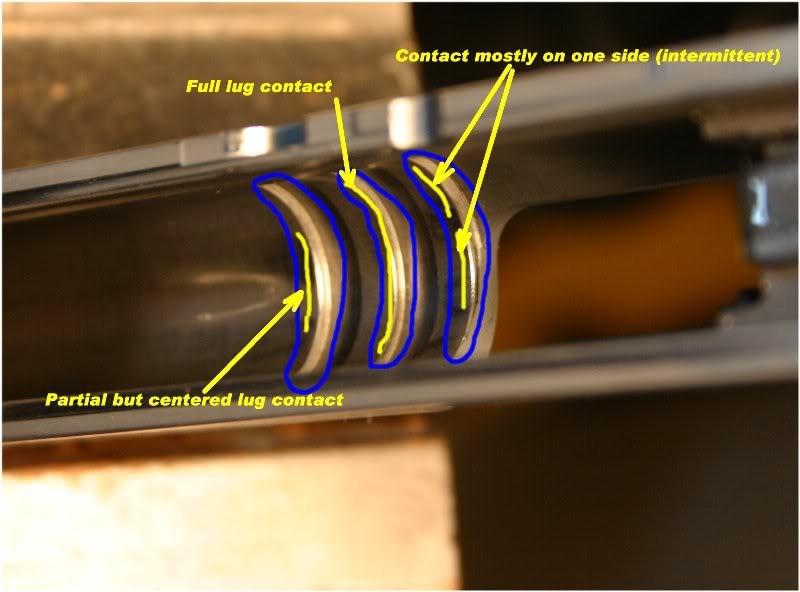

Hmm-m-m. Barrel goes max forward in slide when gun is fired. This means the forward vertical surfaces of barrel lugs/recesses come into hard pressure- locked contact with the aft vertical surfaces of the slide lugs/recesses. Like in this:

And that's where I see the indications of contact on the slide lugs in Eric's photos. What am I missing here?

Exactly why I wanted three lug contact... but the slide and barrel are harder than the original 1911s.

I do want to understand if the marks I see are from "pressure-lock" or cycling... inquiring minds want to know...

Edit added:

Recall that the original 1911 design was build with soft slides and proof pressure ammo was fired by the armorer to equalized the all three lug contact.

Modern modified Browning designs use one large lug because of the advance in materials (hardened slides) now allow/accept one lug.

Quote:

I do want to understand if the marks I see are from "pressure-lock" or

cycling...

An analysis... going on what I can see in the first picture... and that's not really the best way to diagnose it, but...

It looks like the lugs are being deformed from insufficient vertical engagement, and that the barrel fit started out with only lug #2 bearing the brunt. As #2 deformed, it brought #3 into the game, and as 2 and 3 deformed, it eventually got around to lug #1. Slide lug #1 wasn't/isn't dead square to barrel lug #1, hence the uneven wear pattern. Or... Barrel lug #1 isn't dead square to slide lug#1. It's 6 of one/half dozen of the other.

Check the barrel lugs for similar stair-stepping and attendant flanging at the top front corners, and re-check the headspace while you're at it. My guess is that it's grown a bit, though not likely enough to cause a problem.

Now that Lug#1 is coming in, the deformation probably won't progress very rapidly... but be sure to eyeball barrel lugs 2 and 3 for indication of cracking or shearing about every 500 rounds for a while.

Hello and it is great to hear form you Tuner... I will check the items you mentioned and report back...

Quote:

It looks like the lugs are being deformed from insufficient vertical

engagement

This Kart easy fit barrel measures about .042 vertical lockup. The lugs aren't very tall.

Barrel:

Lug one measures .046 (measured between 1-2) (the 91% lockup mentioned above)

Lug two measures .059 (measured between 2-3)

Quote:

Check the barrel lugs for similar stair-stepping and attendant flanging at

the top front corners, and re-check the headspace while you're at it. My guess

is that it's grown a bit, though not likely enough to cause a problem.

Now that Lug#1 is coming in, the deformation probably won't progress very rapidly...but be sure to eyeball barrel lugs 2 and 3 for indication of cracking or shearing about every 500 rounds for a while.

The barrel lug corners are pretty round. I don't see any sign of peening, shearing or anything unusual... but then again I really don't know what exactly to look for other than obvious failures...

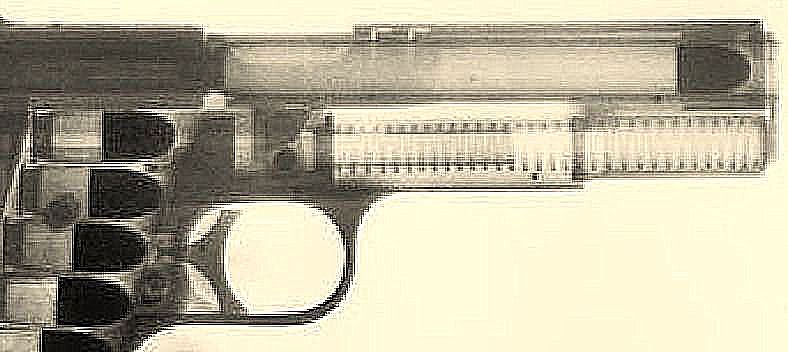

Barrel lugs pic...

Now it's starting to look like a timing problem, with the lower lug striking the vertical impact surface before the upper lugs get clear of the slide... which can also cause the stair-stepped deformation of the slide lugs... if they are deformed the way they appear to be and it's not due to the lighting on your photos. The upper barrel lug corners should be clean and sharp... not radiused like that. Snap a picture from the side of the barrel and post it.

Did you do a barrel linkdown timing test?

You do not have sufficient clearance between barrel hood and slide. It probably was more when built, but in equalization the depth of lug seating increased. I think if you increase the clearance, all will be well... except for filing chrome.

Quote:

I think if you increase the clearance, all will be well.

Not with that barrel, it won't. If it is a timing problem, once those lugs have crashed between the VIS and the slide lugs, the lower lug will probably crack or shear within a couple thousand rounds if it hasn't already started.

There's also the damage to the lugs in the slide to consider. The more that we discover about this one, the more it's starting to look very bad.

Quote:

except for filing chrome

Kart barrels aren't chromed. They're carbon steel in the white.

Quote:

Not with that barrel, it won't. If it is a timing problem, once those lugs

have crashed between the VIS and the slide lugs, the lower lug will probably

crack or shear within a couple thousand rounds if it hasn't already

started.

There's also the damage to the lugs in the slide to consider. The more that we discover about this one, the more it's starting to look very bad.

Kart barrels aren't chromed. They're carbon steel in the white.

I'm sure that you are correct. The filing bit was about a time when the slide needed some relief in addition to some filing on the barrel. I hope that your holidays were OK, and the New Year will be good.

Quote:

Now it's starting to look like a timing problem, with the lower lug

striking the vertical impact surface before the upper lugs get clear of the

slide... which can also cause the stair-stepped deformation of the slide

lugs... if they are deformed the way they appear to be and it's not due to the

lighting on your photos. The upper barrel lug corners should be clean and

sharp... not radiused like that.

I checked that... from what I remember the lugs linked down well before the barrel contacted the slide's VIS... BTW... the VIS looks perfect...

VIS:

I removed a lot of material from the slide bed where the barrel goes to bed to ashure that the barrel hits the VIS before hitting the bed... I probably removed .030+ material...

Barrel bed:

Quote:

Snap a picture from the side of the barrel and post it.

Quote:

Did you do a barrel linkdown timing test?

Yes I did. I did a few of the Schuemann Barrel Timing Tests and everything was OK.

From what I have seen the pistol is setup OK and I have three lug contact.

I was curious about how the number one lug was contacting the slide.

Looking at the first photo of the slide:

It shows that the ejection port cut out, blends into the upper lug. They may have removed a little to much material and compromised contact in that area, hence the lack of barrel lug contact on that side. It doesn't take much.

I like .048 engagement, and it is fairly consistant at placing the firing pin in the center. But I match the two radii, and that makes a huge difference. I can't see any evidence of facing off the front of the barrel lugs? You did a very good job of matching them up..

I'm not worried too much about the barrel to slide lug contact areas because the area has remained consistent throughout the 1800 round of full power 230gr ball ammo. I was curious about how common the pattern was.

I'm not a custom pistol smith but fully understand mechanisms and the fits and clearances required to make them work. I have the utmost respect for pistol smiths who can turn a barrel to match a slide within .0005" to have uniform contact areas... even if I bought a $15,000 gun smith lathe I don't know how to do that!

I noticed that my number one lug contact was offset to the left (probably from my hand fit job) and was interested in hearing everyones experience with lug contact areas.

Good thing that the slide measured in a Rockwell 42 C-scale and the barrel should be hardened too... meaning she should last...

I have no doubts that this pistol will last tens-of-thousands of rounds without a problem...

Here's the back-woodsy method I use to work barrel lug faces without a lathe - so I don't get them too much at an off angle:

There may be better ways to do it without a lathe but at least it's lots better than I could do freehand.

Thank you for the idea Nemi... The truth is that I don't know how to better myself considering I got so lucky with my last hand build... I guess that my next build will take almost two years considering that my that one took over a year...

I will start off worrying about slides and frames and eventually work up to barrel to slide lock-up...

Side view of the barrel gives a different look at the lugs. They look okay. Must have been the camera angle that made'em look radiused.

Still a little concerned about the stair-stepped slide lugs. Are they actually deformed... or is that just contact lines that I see?

The chrome finish is deceiving. When it polishes is looks like an impression or surface irregularity at first glance.

I will attempt to take better pictures tonight and even try to take some measurements from the hood forward to the lugs.

The good new is that the horizontal barrel play, I think its called end play, hasn't increased. I fit the barrel with .006 inches of play and it hasn't gotten any worse.

Eric, on the next barrel you fit, try for zero clearance. The prominence of the engagement contact marks will diminish, and will actually stress the engagement surfaces less.

Well I was wrong about not gaining end play... end play increased from .006" to .007" which seems reasonable while the lugs equalize after 2000+ full power rounds.

I will take Jerry's advice and build the next one tighter... experiecne helps.

Here is another view of the slide lugs...

They are still sharp looking... I guess they look the same as when I started... I will admit that I stoned the corners just a teeny weeny bit when I fit the Kart barrel.

Quote:

I will admit that I stoned the corners just a teeny weeny bit

I do it all the time. Sharp corners is poor engineering. I also radius the cutter to produce a small fillet in the barrel lug corners.

FWIW, the Ordnance slide blueprint specifies a 0.010 to 0.015 inch chamfer or radius for those corners. Those on the barrel get a 0.005 to 0.015 inch chamfer.

Will the pistol have cycle problems when dirty if I build the next one line- to-line (zero gap)?

No; A close fitting Bullseye gun must run for 90 shots between match aggregates.

Reliability is paramount. Many competitors shoot both aggs without cleaning. 180 shots. Myth and wive's tales die hard. Before I retired from the PD, I over saw 800 + Sig pistols. They lock up hard at the breechface. Zero clearance, never an issue. As a ridiculous test, we fired one pistol uncleaned for over five years. 10,000 + rounds. It never malfunctioned. Would you build .006 clearance into your car connecting rod or main bearings? Of course not.

Quote:

Would you build .006 clearance into your car connecting rod or main

bearings?

Hello and thanks for the reality check and you have the experience that I respect and admire... and thank you for your service.

My Sig P226 is tight like you mention, so is my Walther PPS.

The truth is that I targeted/started with .003 clearance but when I dychem'ed the lugs and whacked the barrel I started chasing ghosts a little. I got a little carried away and ended up with .006. I was a little embarrassed with myself but hey... no-one knew... until now...

I originally decided to build it with .003 clearance because 1/2 the "experts" said you need a gap for reliability and the other 1/2 said that you need zero for accuracy so I compromised on a fictitiousness / made up value of .003... a total feel-good number with no basis at all...

Next time... hopefully soon if I can find the "right" frame/slide... I will target .0000 and end up with less than .003...

Quote:

I was a little embarrassed with myself but hey... no-one knew... until

now...

In all these years, I've trashed a few parts myself... barrels, slides, frames... It happens. Hopefully/thankfully not very often... chambering/headspace was a weak spot for me years ago. It's really hard to hit that number right on the mark when free handing a reamer. Almost impossible. I chamber in the lathe, but came up with a reamer stop to prevent over shooting the depth. The benchrest crowd has devised an adjustable stop. Not needed with the 1911 or .22 since they are all the same... in most cases.