The first step in porting your 1911 is to disassemble your gun. Now before you get too excited, you are gonna need to scrounge up an extra barrel. If your 1911 uses a barrel bushing you will need this extra barrel or junk barrel to keep the bushing in place while we cut the 1/4 inch slots, so that we can notch the bushing as in (Fig 7).

Assemble your slide, bushing and junk barrel. To keep the barrel in chamber you will need a Barrel holder (Fig-1).

The barrel holder from Brownells will hold all pieces together during your machining step. I turn the vise sideways for the next step and then clamp slide in and level.

Turn head of mill to 25 degrees and place a 1/4 four flute carbide mill bit in collet, spinning at 1100RPM. You can either use a ball end or end mill bit; I have used both and either works well. If using the ball end you must plunge deeper though. I want my 1/4 inch slot to start .200 from end of slide, and to extend exacly one inch. The slot should be about .075in from the front sight on either side (Fig 2).

Just a little note here in case it is not obvious; once you think you have lined up your bit and you are ready to plunge, do not raise or lower the table. All plunging must be done with the handle on the head of the

Once both slots are cut in slide, remove from vise and you should notice your barrel bushing was notched properly. Remove junk barrel and clean slide and reassemble with good barrel and place back in vise. The next step is drilling the five holes on each side of the barrel. You need to ensure you have the head lined up properly on the slot you just milled, or else the five holes you drill in barrel will be too high or low in their respective slot. To ensure I have head lined up with slot, I place a 1/4 end mill in collet upside down, then move table until the back end or solid part of mill bit will go into slot.

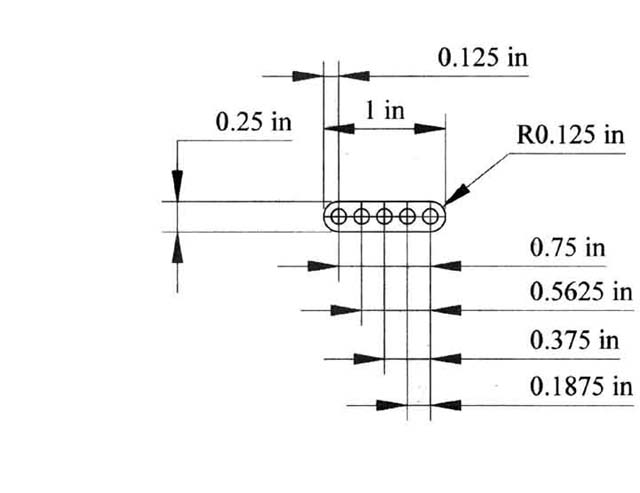

Then replace 1/4 collet, with a 1/8 collet and a carbide 1/8 ball end bit (or a good cobalt stub length drill bit), the spacing is in (Fig 8).

I usually spin the bit at 2720 RPM. It is extremely important that bit is brand new and very sharp, as it must drill a hole in your barrel and not leave a burr on the inside when it breaks through. I have done three barrels now and have not had a problem as of yet, but I use high end cobalt bits from a machinist catalogue and only use new bits for every job. Practice on your junk barrel. When you finish I think you will be quite surpised at how much muzzle rise is reduced on a little gun. Good luck!