My Norinco's barrel lower lugs are too far forward. It failed the swinging slide stop arm test and there are no impact marks on the backside of the lug (link stopping the barrel?). I tried a longer link but started to have feed problems. It still failed the swinging arm test with the longer link (Wilson #5).

I gave up on the Nork barrel (it is soft anyway, right?) and bought a blued ARMSCOR for $50. The ARMSCOR barrel seems to fit the Nork pretty well without any smithing. It passed the swinging slide stop arm test with the Nork bushing and link (.278). It even passed the test with a Wilson #5 link (is that possible? Or might I have done the test incorrectly?).

The gap between ramp and throat seems correct also. Barrel hood can't be pressed down when the gun is in battery. The lower barrel lug rides the pin at the front convex radius and into the straighter portion of the lug. The pin is snug at the concave lug radius in lock-up (link hole is slightly below flush).

The gun functions smoothly and is VERY accurate - I can consistently make three holes touch each other at 7 yards. 12 rounds would go into a 3-inch group at 14 yards, consistently. But the POI is about 4 inches high of POA and it's about an inch to the left.

Reliability with ball seems ok (not much shooting yet). I did try 100 rounds of LSWC - lots of FTF/failure to go to battery with standard 7 rounds Nork mag, CMC Power10, Novaks Mag and Cobramag. Polished the barrel ramp shiny with 1000 grit sandpaper. No improvement in feeding LSWC. All test shooting were done with the .278 link.

I measured the slide lugs and barrel lugs. Differences are (from lug 1 to 3) .009, .0098 and .019. There are shiny impact marks on lug 1. It's corner is sharp but there's a little shiny portion on top. After another 100 rounds some shiny impact marks are visible at the upper part of the front face of lug#2.

Barrel lug#1 measured .0386 high (short?). I did the lock-up measurement. Using .0386 lug height as the divisor, I'm getting 85% engagement at lug#1 with the Nork link. Since my lug height is shorter than the usual .050 I must strive for a deeper engagement right?

Can I go to .281 or .283 link to get a little more vertical lock-up and bring the POI down? Or is it best to ask a smith to bring the slide a little lower since I'm already getting good accuracy with the .278 link? Is there anything I can do to make my gun feed LSWC reliably?

If the first lug is indeed bearing the horizontal brunt of lockup, you're probably okay for standard hardball-spec ammo with .038 inch vertical, provided that the headspace is mid-spec. I wouldn't shoot a lot of hot-rod +p ammo in it. Also, if the #2 lug is within kissin' distance... about a thou or two...i t'll likely start to come into play within a couple thousand rounds, and help #1 out. Due to the barrel tilt, you won't have quite as much engagement on #2, but anything that it does give helps.

I'm fairly anal over maximum vertical and equalized engagement... but that's probably because I shoot so many rounds annually. Barrels are expensive.

Replacing one per pistol every 16-18 months just ain't my idea of a whoopin' good time.

Almost forgot! Although you can get the lugs a little deeper into the slide with a long link, it's best not to go that route. Usually causes more problems than it solves. Possibly expensive problems...

Thank you for the quick reply. I'm not getting the entire .0386 height of barrel lug #1 to engage, just ~ 85% of that (~.032). I almost exclusively shoot reloads (~170 power factor) so I guess the barrel would make it through a few years of shooting?

What would be the consequence if I tried shooting the Nork with .281 link (Marvel +3)?

Been struggling to post some pictures. Might be able to add them later.

The 3 Wolff SS 7-rounders with the 11# springs that I ordered direct (sold my 3 CobraMag 10-rounders to finance the purchase) came the other day (do they perform as well as the similar metalform?). Got them instead because they're cheaper and already came with the recommended spring and I can't seem to find the Metalform 7 rounder with flat dimpled follower on their website nor at Brownells. Now the Wolff mags in the configuration that you favor are also no longer available in their website, I must have been lucky enough to get their last few units . Tried some LSWC, they fed ok. 'Will try to shoot some more to test them thoroughly. I really want to make this gun work with LSWC. I also came across an article 'bout the Pachmayr follower (#692-702-000) being reliable and feeding LSWC smoothly. Do you have any experience with them? They don't look dimpled but the configuration of the follower seems to achieve the same "braking" benefit that the dimple provides.

BTW do all new production 1911 have difficulty feeding LSWC or is it just my Nork?

Set your seating die with a round of factory ball ammo. After that a gun that is decently set up should function with SWC ammo, if it doesn't try to get some pictures or a really good description of the failure.

My last couple guns run SWC flawlessly, but I set my seating die a LONG time ago and left it alone since.

quote:

Thank you for the quick reply. I'm not getting the entire .0386 height of

barrel lug #1 to engage, just ~ 85% of that (~.032). I almost exclusively

shoot reloads (~170 power factor) so I guess the barrel would make it through

a few years of shooting?

The answer is... it depends. .032 vertical is only 64% of what it should be, assuming that the first lug is bearing the brunt horizontally, it'll last longer than it would if it was engaged at 64% of just one of the others. The first lug is the strongest. The other two aren't as well supported in the rear because of the slots behind them.

If you have 64% of the first lug bearing the load AND one of the others is also taking a share, it'll last longer still... but still not to its full potential.

.032 inch is what you have on the first lug, since that's all you can measure without using other methods. The barrel tilts up into battery, which means that you'll get a little less on the second lug, and a little less than that on the third, assuming equal lug dimensions. When you get into the 60% range, you're treading on thin ice, especially if the barrel has very much fore and aft play in the slide. Of course, the lighter your ammo, the longer it'll remain serviceable.

What happens is... As the front faces of the barrel lugs start to deform, the headspace increases by the amount of deformation. Simply put... If the lugs set back by .010 inch over the course of time, the breech will open by that amount when the gun fires because the slide and barrel are going in opposite directions until the lugs engage and lock them together. Whatever slack is there before the lugs stop the separation is the distance that the case will back out of the chamber under pressure. As the case backs out, case head support is lost.

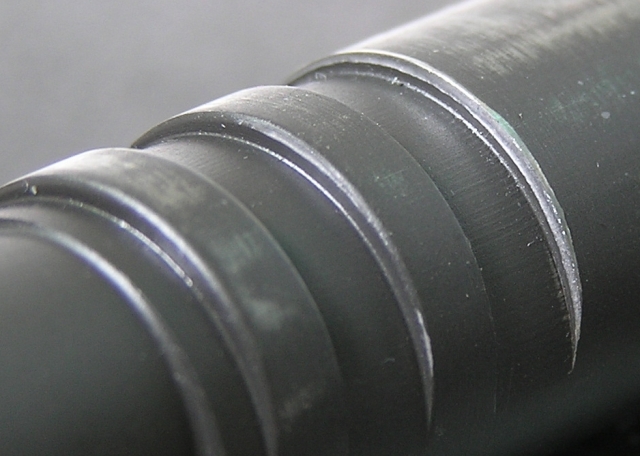

Keep an eye on the barrel lugs for any sign of setback and flanging at the top front. Keep a close check on your fired brass. If you start to see bulges just ahead of the web area, or even feel more resistance as they're almost all the way into a sizer die... you've got a problem that... if allowed to continue... will likely cause a case rupture sooner rather than later.

Thanks Tuner. I'll keep an eye on those lugs and those fired brass.

For now, brass don't look bulged near the base. Lug#1 has some shiny part on top just at the corner. But the lug edge is sharp to touch and looks square (no rounding off).

Barrel doesn't seem to have much fore and aft movement. With the slide and barrel/bushing off the frame, I held them in the locked position in front of the PC monitor and looked for a gap between the hood and breech face. Pushing the barrel back, the barrel hood very lightly touches the breech face. Barrel pushed forward, I could see the gap become wider but still could not insert the corner of a dollar bill thru. Since rounds are flush with the hood, my headspace is probably on the safe side?

If I used the .281 link (sorry, Tuner, I know you said it's best not to use them long links - I just have to ask) what danger signs should I look for?

HSMITH,

I'll try to get pictures of the hang-up next range session. It's basically a

failure to feed. The leading edge of the round seems to bypass the frame feed

ramp, hits the barrel ramp/throat low and gets wedged on the sharp bottom part

of the throat. Deep gorge mark on the lead is visible on rounds that failed to

chamber. This appears to happen more frequently with the mags that have a high

feed angle (CobraMag and CMC Power10). I also have Novaks mags, FTF also

happen with them. The least number of failures are when I'm using the mags

that came with the Nork. I just recently received Wolff 7-rounders. I'm yet to

experience the hiccup with it. Not much rounds have been fired using the Wolff

though.

I don't load my own ammo. I get them from a local gun store. The LSWC average 1.261 in length. I think it's the slim profile of the leading edge of the bullet that's causing the problem. I believe LRN rounds are deflected up a little by the frame feed ramp because of its rounded shape and approach the chamber at a more acute angle missing the sharp bottom edge of the throat. Never get any FTF nor any other jams with those. A buddy loaded me 100 rounds of his LSWC. All 100 went bang with no trouble. 'Buddy's SWC have a little 'fatter' nose. Hope I can get those pictures soon.

Quote:

Since rounds are flush with the hood, my headspace is probably on the safe

side?

Has not one thing to do with it. You can have a dead flush condition there and still have excessive headspace... or non-flush and have good headspace. The only way to know is to gauge it.

Read the sticky at the top to understand it better.

Long-linking a barrel will increase vertical engagement, but it can also bring on other problems... sometimes expensive ones. For one thing, it delays linkdown and drop timing. That, in itself isn't necessarily a bad thing unless it's delayed enough to let the back of the lower lug hit the frame's vertical impact surface before the barrel lugs are clear of the slide's. It also very often places added stresses on the link's pin and the hole that it's pressed into. Generally, not a good idea.

Tuner, the flush round and the minimal fore aft barrel movement. Does it mean anything good?

I'll leave the .278 link alone and just watch the lugs...

quote:

"Tuner, the flush round and the minimal fore aft barrel movement. Does it

mean anything good?"

Probably... but it's not a guarantee. As a wise man once said... can't remember who offhand, but I think it was Ned Christiansen...

"I only know what I can measure."

You can use strips of paper of a known thickness and get a close idea of the endshake by placing them between slide and hood and letting the gun go to battery. When you get to a thickness that won't let you pull it out without tearing it... measure that and subtract .001 inch, and you'll be close.

Measure the length of a fired case and slip it under the extractor and into the barrel... slide off the frame. Let the barrel drop slightly and slip the paper strips between the rim and the breechface. Push the barrel back into the slide. When you feel a good amount of resistance in getting the barrel all the way up... measure the strip and add it to the length of the case. Again... not precise, but it'll get close. If the total is more than .920 inch, headspace is excessive. If it's below .898 inch, the headspace is below minimum... which you probably won't find in your gun.

Excessive doesn't automatically mean that it's dangerous... only that the length of the chamber from breechface to shoulder is beyond ordnance allowable spec.

Thanks for the instruction on how to measure the headspace using only a fired brass and some paper strips. I might get myself some feeler gauges though to make things easier and a little bit more accurate - I need to check the headspace every now and then anyway, right?

Tuner, can I remove the extractor while doing the measurements? Thought it would make putting in the fired brass in the chamber during the exercise easier.

Just got a package from EGW the other day. The OS FPS with square bottom is now in the Nork. Took awhile to file it down to where it would just snap into place with finger pressure.

Finally got those feeler gauges, brought them to a local machine shop to have them tapered down to around 1/4 inch at the tips.

So with the ARMSCOR "drop-in" barrel in the Nork slide;

End shake = .009

My fired brass = .888

I could get the .023 gauge (but not the .024) in between the brass head and breech face with the brass in the chamber and the barrel pushed forward in the in-battery position in the slide …the rounds were not flush with the hood after all (my eyes are getting tired after years of hard use it seems and your friend Ned was right).

.888 + .023 = .911 static headspace. Correct?

That gives me about .009 allowable setback before the max .920, IF my measurements were accurate.

When the barrel was new (unfired) the differences between front faces of barrel lugs to hood AND backside of slide lugs to breechface from 1 thru 3 were .009, .010 and .019.

I got the chance to measure the headspace after a few hundred rounds. At that time the 2nd lug was already in contact with the slide meaning the 1st lug has seated about .001 inch back (barrel lugs 1 and 2 equalized). So, at this time that the static headspace is .911 the 3rd lug is ~.009 shy of touching the slide lug. Now, I only need to watch the face of the 3rd barrel lug for signs of contact with the slide before I would again seriously measure the static headspace - because by then headspace would have grown to .920 or thereabout.

Tuner, am I good to go?

Batoy wrote:

.911 static headspace. Correct?

That gives me about .009 allowable setback before the max .920, IF my

measurements were accurate.

.911 is close enough for government work, I'd say. You may have more allowable setback than that. "Headspace" is defined as the difference between the case length and the static dimension. The static dimension only tells you the length of the chamber from breechface to stop shoulder... not which direction the extra headspace comes from. For instance, if your gauged dimension was exact, you have .013 inch over the .898 minimum.

That excess amount can come from the chamber being cut too deep or from the amount of breech opening allowed when the gun fires... when the barrel and slide are pushed in opposite directions, before horizontal lug engagement.

If that .013 inch is evenly divided between the two... which is probably isn't. you have .0155 inch (.009+.0065) of setback allowable before headspace becomes potentially dangerous... which would also put it a little over the .920 inch maximum.

So... go back to the ordnance NO GO gauge to tell you when things have gotten excessive. If the gun goes to battery on a .920 NO GO gauge... it's out of spec.

It'll take me a little more time to digest the numbers you just sent. Tuner.

I think I'll go out and shoot some more - comfortable in the fact that I have a safe 1911 in my hands that will not send hot gases and pieces of brass down the mag chute anytime soon.

Since I'm still trying to understand this headspace thing: does wear on the shoulder of the chamber and wear on the breech face contribute significantly to the increase in static dimension with use or is it insignificant compared to the wear on the locking lugs?

Batoy asked:

Since I'm still trying to understand this headspace thing: does wear on

the shoulder of the chamber and wear on the breech face contribute

significantly to the increase in static dimension with use or is it

insignificant compared to the wear on the locking lugs?

I wouldn't say that it would be a signifigant contribution, but anything that can wear will wear sooner or later... and any wear that contributes to increasing the static dimension will increase the working headspace.

To help you digest the numbers a little easier...

If you start with theoretically "perfect" minimum headspace, in which not only the static dimension is minimum, but also the barrel and slide specs combine to create a case that is located in the chamber so as to provide the maximum case head support. This theoretical perfect barrel to slide fit has zero endshake, and all lugs are bearing equally in the horizontal engagement.

This is also known as "Zero Headspace."

We also assume a theoretical case length of .898 inch.

If you remove .005 inch from the face of each lug, you have .005 inch of headspace and .005 inch breech opening under pressure. This is an increase in headspace in the dangerous direction. Equate it to lug setback/deformation.

If you simply reamed the chamber deeper by .005 inch, you'd still have .005 inch of headspace... but you don't lose case head support. This is an increase in the "safe" direction. Equate this with short case length.

If you ream the chamber AND remove material from the lugs, you have .010 inch of headspace... half of which is in the dangerous direction and half in the safe direction.

Remember... Static headspace only changes with wear, and lug setback and deformation. Working headspace varies with case dimension. In your theoretically perfect gun, one round may have zero headspace, and the next one may have .010 inch... such as with your .888 inch test case. With the short case/deep chamber, the potential negative result is mainly erratic primer ignition... or misfire if it's excessive.

So... Headspace comes from two directions, and most factory guns provide it with a little of each. The GO and NO GO gauges only tell you that the chamber length from breechface to chamber shoulder is within allowable tolerances. Into battery on the GO gauge means that the gun will chamber the longest case that is within SAAMI spec. Into battery on the NO GO means that the static chamber dimension is outside of acceptable parameters.

It doesn't necessarily mean that it's dangerous... only that it's not within allowable tolerance.

Tuner, the theoretical part was easy enough to understand. It was the numbers that got me all confused. So please be patient with the following d_mb questions/assumptions...

quote:

"If that .013 inch is evenly divided between the two...which is probably

isn't."

In my barrel/slide setup, the .013 departure from the minimum .898 would be .009 of breech opening (endshake?) and .004 deeper chamber over the minimum .898 = .902 distance from chamber shoulder to end of hood (or .888 brass + .023 feeler gauge = .911 - .009 of breech opening = .902 - .898 SAAMI minimum = .004 inch deeper chamber than minimum).

I have a tendency to over analyze, so if this is the case, please don't hit my hands...

quote:

the ".0155 inch (.009+.0065)"

is based on the assumption "if the .013 inch is evenly divided..."? Which .009 is this?

In my actual barrel/slide, this line would be... .018 inch (.009+.009) since my chamber is deeper by .004 and not .0065?

So, my total allowable setback would be .018?

This is giving me a headache ...but hey, no pain no gain, right?

Without havin' the gun on the bench with all attendant gauges and measuring tools... I'd say that the endshake is making up the bulk of your .013 inch of headspace... which would make it in the bad direction... with the remainder being in the chamber depth. Again... this is no more than a guestimate... but it'll getcha pretty close.

Other factors that would change the bottom line would be chamber diameter... Barrel ramp geometry... (Over-throated)... operating pressures of the ammunition lot... and brass thickness and/or hardness.

Strong brass that is thick in the area forward of the web won't pose as much danger of case bulge/blowout with standard pressure ammo as would +p loaded in thinner brass. I've seen barrels that were grossly over-throated that didn't bulge thick brass... and seen a few that appeared to be okay, but with just a little too much headspace in the wrong direction that bulged it to the point of rupture. The clasic "Guppy Belly" appearance.

Final analysis... Keep an eye on the fired brass and listen to what it's telling you. Don't ignore even a slightly bulged case.

Now I feel a lot more comfortable with this set-up. I know it's not perfect but feels that it's much better than with the original Nork barrel. Armed with all the new knowledge, I'll keep an eye on those brass...

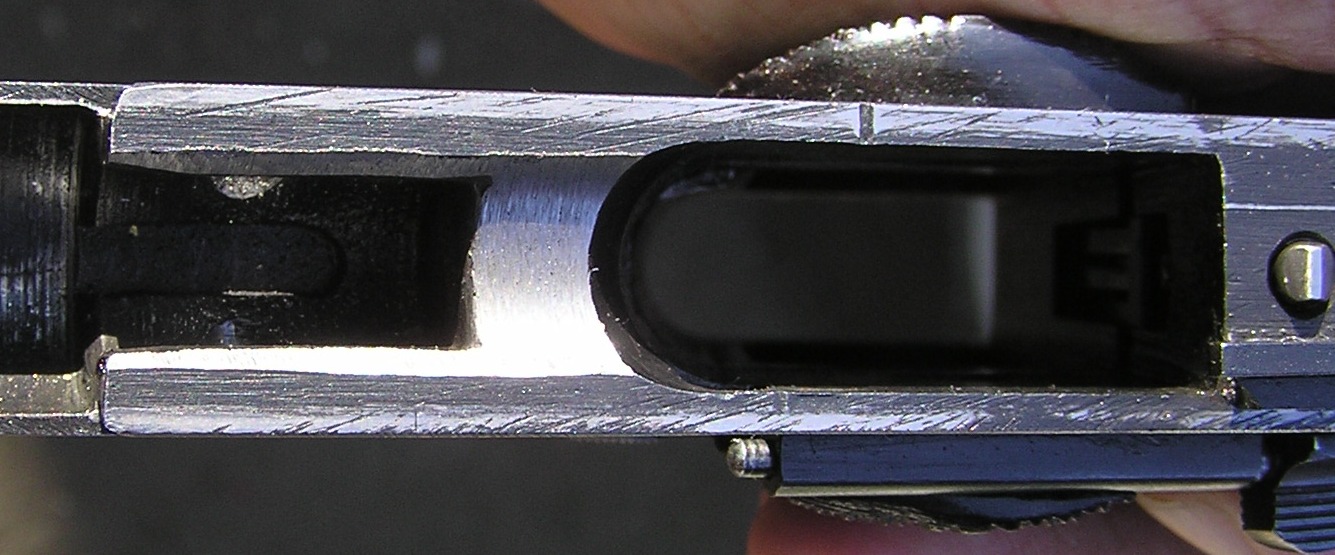

Sorry for getting back to this old thread. I recently got a PM from one forum member who was interested to know about how the Nork with the ARMSCOR barrel is doing so far. I promised him some pictures. Here they are.

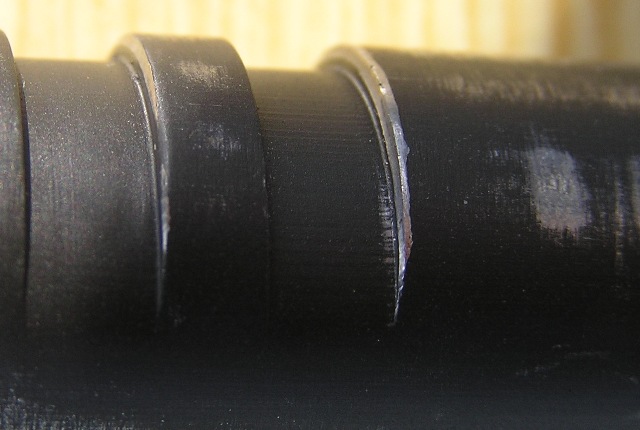

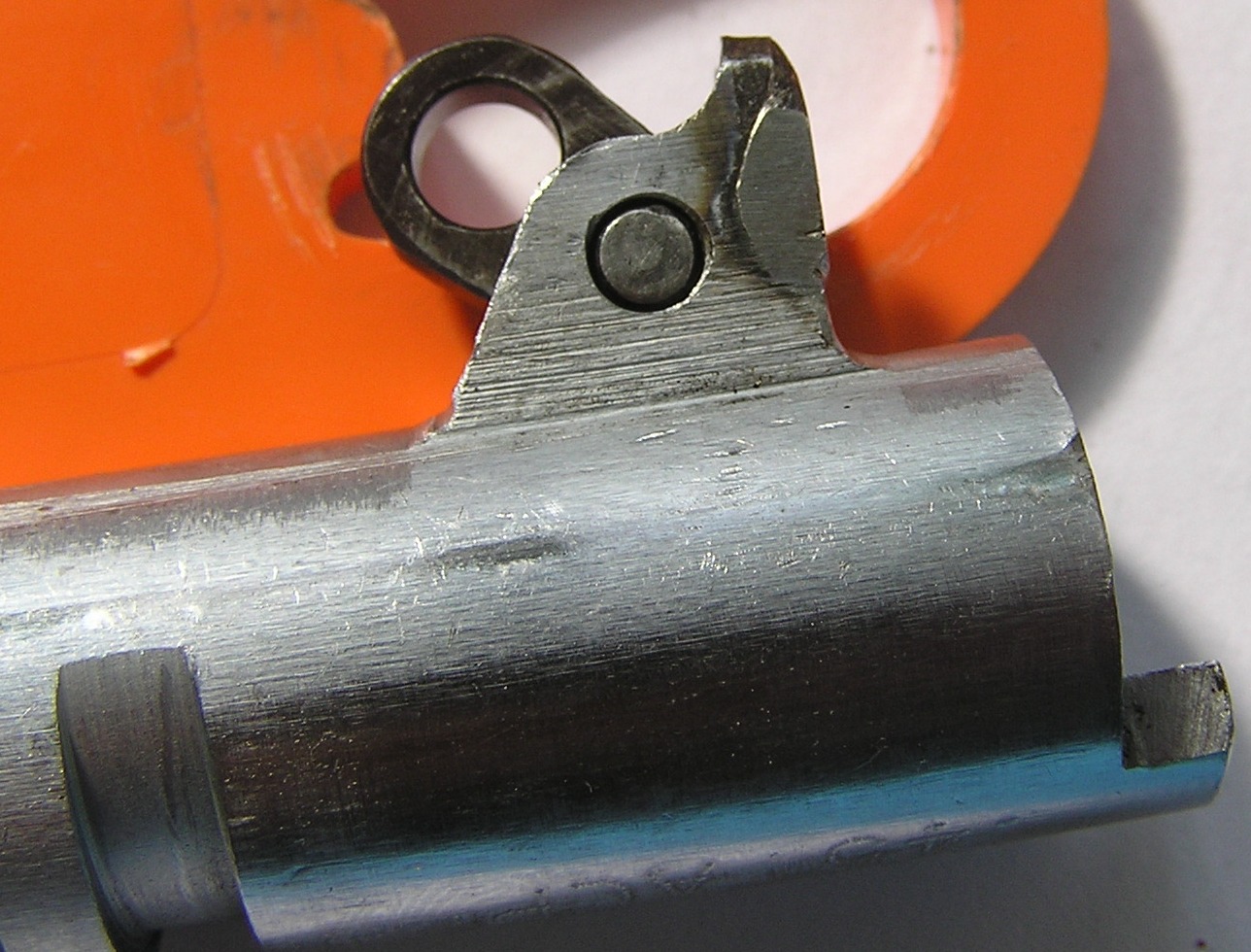

Batoy... Unless the light is playin' a trick on my agin' eyes... you've still got a problem. Take another shot of those lugs from the side for me.

They look rolled to me too Tuner...

Dangit! There's either a linkdown/drop timing problem or not enough clearance between the barrel and the slide when the barrel goes to bed.

Sorry batoy... This pistol's been a real pain for ya.

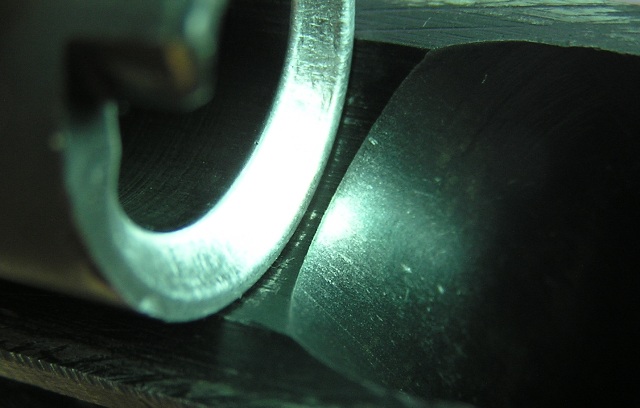

Here are some older pictures of the barrel. The last in the series was taken today just before I applied some cold blue on it.

Is it the shiny portion at the top of lug#1 just at the front corner? I noticed that earlier on, so I decided to take photos to monitor how bad it will become.

Some more info on the gun;

The shiny wear mark on top of lug#1 started to appear after only a few rounds. I was using Link#3 then.

Some time ago, I decided to replace the Nork slidestop with an EGW OS slidestop. With the .278 link, there was a noticeable lower lug/slidestop pin binding. The slide would not totally close if it was allowed to go to battery slowly. I slight push at the back of the slide and the slide would snap shut. I replaced the link pin with the Marvel +3 (.281). It made the gun function smoothly. Gun was reliable with hardball.

Tuner, with you (and HSMITH) around it becomes less of a pain and more of a learning opportunity.

Looks like a clearance problem...

I've seen a thread on this, I think. Let me look for it.

I see two things, the hood is short so the barrel gets whacked pretty good against the lugs when the bullet yanks it forward, and the lugs are rolling pretty darn bad when it drops out of lockup. The other part to this is that #1 lug is taking 75% of the load, #2 is taking 25% and #3 is just about skating by unscathed. This has been going on a while and the odds of things sorting out on their own as a normally fitted pistol would are between none and none.

Just from a casual observation it looks like it is linking down early, well before about .125" inches of slide and barrel travel locked up tight. I don't honestly know what this is called, I call it 'dwell time', thinking that the barrel and slide recoiling together without any change to the relationiship of the two parts as being a 'dwell' before unlock starts. This gun in the pictures has pressure applied to the case during unlocking, that locks the barrel to the slideand rolls the edges of the lugs as it unlocks. The gun is a 45 and this is by far the most forgiving of the cartidges the 1911 has been asked to handle. The slide is probably worse off than the barrel at this point.

Batoy, you have been a real trooper and worked honestly on this. I don't know much other than direct and I hope you take this as I intend it, but right now you need to get this gun in the hands of someone that is intimately familiar with the design and more importantly knows how to 'read' what the gun tells him and knows what to do from there. Tuner tries to play this part off, but he can truly 'read' what a gun wrote, tell what it needs, and get it there. A lot of readers buy into his 'armorer' and 'tinkerer' story, but it just ain't so. That man can look, listen, and know what a machine needs. Call me crazy, but I would bet a steak dinner it ain't just on the 1911 platform......

I was hoping there's some more "home remedies". Guess this one needs a specialist now, huh?

I've developed some kind of attachment to this gun and sure do not want to part with it. Used it to win 2 Championship trophies in IDPA style Regional Competitions. Hope the surgery isn't a major one. 'Hope too that the barrel is salvageable. Don't want to buy another one. This is an inexpensive gun and I'd like to keep it that way. Don't see the value in buying a $200 barrel to remedy a problem on a $280 1911.

Hey thanks so much HSMITH, Tuner. Around here people don't seem to worry about such stuffs as lugs and timings and clearances all that much. They just scratch their head when they break a pin or a lower lug or a link. I'm just glad you guys took notice of the photos I posted. Now if I can just find a good gunsmith...

Our esteemed Mr. Smith seems to be a pretty "Pistol Whisperer" in his own right. Early linkdown while the pressure is still in effect will tend to bevel the corners of the lugs, as these look to be... while insufficient drop clearance from a mislocated vertical impact surface... too far forward, or lower lug...too far rearward... tends to round them off or shear them outright in extreme cases.

The telltale sign is a stretched link. The trick is to determine whether the stretching occurred because the barrel was being stopped by the link... VIS located too far rearward/lower lug located too far forward, or from the barrel reaching the linkdown position while the bullet was still in the barrel, with pressure still holding the lugs in lockup... or simply a too-short link, which will also stretch as the barrel's rearward momentum places tensile stresses on it.

If it stretches because of VIS and/or lug mislocation, the damage usually shows up as rounded corners because as the link stretches, it lengthens... which delays barrel disengagement. The rear face of the lower lug strikes the VIS before it can clear the slide lugs... and the result is identical to having the barrel stop too early on a VIS located too far forward.

The beveled corners suggest early linkdown, possibly caused by a too-short link. There's a test for this. Push straight back on the muzzle until it stops.

Look to see if there's a small gap... about .101-.012 inch... between barrel hood and slide. If it's not there, either the VIS is too far forward, or the lower lug is too far rearward, and the barrel is stopping before it can disengage from the slide.

If it's there, proceed to:

Tilt the muzzle down at a 45 degree angle and cycle the slide briskly. If it hits a hard spot about a quarter-inch out of battery, but cycles normally when the muzzle is parallel to the floor, it's short-linked. To confirm a short link, move the slide a little past a quarter-inch out of battery and press down on the hood. If the hood drops lower and springs back up... it's the link.

Then:

Tilt the muzzle down at 45 degrees and cycle the slide briskly. If it hits a hard spot, it's long-linked. To confirm, hold the pistol upside down and hold the slide out of battery a little past a quarter-inch, and look to see if there's clearance between the top of the barrel and the slide bridge formed by the first lug wall. If it's not there, push the barrel toward the bed. If it moves far enough to provide ample clearance... it's the link.

To check for VIS located too far rearward, or lug too far forward, install the slidestop pin with the arm hanging vertically. Push the barrel firnly to the rear and hold it. The slidestop should move freely, with no binding. A tiny amount is acceptable, but should require no more force to move the arm in an arc, than a very light flick of a fingernail. This part also reveals a short link, but the other tests should be used to verify that it is the link and not something else in the frame's specs.

I am using the .281 link (Marvel +3) because it is the shortest link that passed the swinging slidelock arm test I did in the past. Incidentally, both the #4 and #5 links from Wilson also passed the test.

"Push straight back on the muzzle until it stops.

Look to see if there's a small gap... about .101-.012 inch... between barrel hood and slide."

The gap is there, Tuner.

proceeded to:

"Tilt the muzzle down at a 45 degree angle and cycle the slide briskly."

Slide cycles with the gun pointed at 45 degrees down the same as when it's cycled horizontally... smooth - no hesitation whatsoever.

Did the confirmatory test for the short link just the same. Hood could not be pushed further down.

To confirm if the link is too long.

"To confirm, hold the pistol upside down and hold the slide out of battery a little past a quarter-inch, and look to see if there's clearance between the top of the barrel and the slide bridge formed by the first lug wall. If it's not there, push the barrel toward the bed. If it moves far enough to provide ample clearance... it's the link."

Upside down, slide retracted >1/4 inch out of battery... no gap. Hood pushed down to bed... ample clearance created. The link is longer than necessary to clear the lugs in time?

"To check for VIS located too far rearward, or lug too far forward..."

With the .278 link, the gun failed this test. With the .281, .283 and .288 links, the slidestop swings freely and would fall out of the gun if I tilted it on its side.

I did all the tests with the gun fully assembled except for the last test. Was I able to follow you, Tuner?

Further, with the gun upside down and slide retracted a little, if I released the slide slowly to battery under recoil spring pressure, I could feel the edge/corner (same portion showing the bright wear mark on top of lug#1) of the first barrel lug catch on the slide lug... if that means anything.

Quote:

Upside down, slide retracted >1/4 inch out of battery... no gap. Hood

pushed down to bed... ample clearance created. The link is longer than

necessary to clear the lugs in time?

Long link. The barrel isn't being disengaged from the slide in time. Since a shorter link fails the slidestop arm "swing" test, either the vertical impact surface is too far rearward... the lower lug is too far forward... the link pinhole in the lug is mislocated rearward... or the slidestop pinhole in the frame is mislocated forward. Also a possibility that the link pinhole is mislocated low on the lug. Gonna take a lotta measurin' to figure out what's out of spec. Since most critical dimensions are measured from the slidestop pinhole... start there and measure from the center to the VIS and to the tops of the frame rails.

center of slidestop pinhole to the VIS = 0.442

center of slidestop pinhole to the tops of the frame rails = 0.442

I also measured from the center of link pinhole in the lug to the backside of the lower barrel lug = 0.259

Measured the right and left sides. Differences seem to be less than 0.001

quote:

center of slidestop pinhole to the VIS = 0.442

Assuming that your measurements are precise...

Your VIS is too far rearward. Spec is .431-.436 inch, so you're .006 inch further rearward than maximum allowable and about .0085 further than mid-spec. In order to know exactly, you'll need to use a pin that closely fits the hole.... measure... and subtract half the diameter.

quote:

center of slidestop pinhole to the tops of the frame rails = 0.442

Spec is .445-.450 inch. Assuming a correctly sized pin to measure from, it's .003-.007 inch too high. Workable with a .278 link, though vertical lug engagement will be a little less than optimum.

quote:

I also measured from the center of link pinhole in the lug to the backside

of the lower barrel lug = 0.259

Spec is .254-.258 inch. Assuming that the lug is located corectly at mid- spec, the rear lug face is anywhere from .001-.005 inch too far forward.

Added to the .006-.009 inch VIS mislocation, and the stackup has your barrel stopping on the .003 inch longer link with a .003 inch gap between lug and VIS... which is about right, since you said that the .281 link is the shortest one that passes the swing test.

The problem is that the link is too long to get the upper lugs out of the slide in time to prevent the crash that you've got, and using a shorter link will place stresses on the link, link pinhole, and lower lug. The link will either stretch until it fails to get the barrel out of the slide... or it'll break, causing a hard crash due to not linking the barrel down at all... or the lug will crack at the rear junction with the barrel.

Yow! Not good. Trusting Tuners math it seems that a Clark/Para ramped barrel is going to be the easy/cheap-ish/viable repair, that is if the barrel hasn't molested the slide too badly yet. $300+ for the installation I would imagine...

I used the EGW slidestop which is claimed to be .2000+/-.0005. Put it in and measured to the VIS. Added half of the .2000 to the distance from the pin to VIS. Measured the thickness of the metal from the pinhole to the top of rail then added half of .2000.

Definitely the setup is not gonna last long, huh? Think I'm goin' to buy a new barrel then. I've been meaning to buy a Kart Hard Fit barrel anyway.

HSMITH, you beat me to the keyboard. I'd like to keep a standard configuration if its workable. A standard OS gunsmith barrel perhaps? BTW there's some wear on the back side of lug#1 on the slide but it's just at the edge. I have fired maybe less than 500 rounds with this setup. And the amount of metal crashing is small owing to the shortness (only .0386 tall) of the ARMSCOR barrel's locking lugs, I suspect.

With the VIS out of location you will either have to weld it up and have it cut to the proper location or put in a ramped barrel. The ramp cuts remove the standard VIS and relocate it. I don't have any problems with ramped barrels in 45, but some don't like them.

I can do the ramp cuts and barrel installation myself, so all it would cost me is the price of the barrel. If I couldn't do the installation I would probably just retire the gun and get another one. $300+ to repair a $400 gun is a hard decision to make.

Building up the VIS seems to be the cheapest alternative. I have access to a shop that can do nice weld jobs. But I guess there's some special type of welding that's right for the purpose? Will welding in any way affect the "hardness" of the metal?

It needs to be TIG'd/GTAW'd. Send it to George Smith at EGW to get it done correctly.

Thanks for the advice BBBBill... Geo is a nice guy to deal with.

Excellent thread. A learning experience.

Desperate to make it work... I guess

Had the lower lug of the Nork barrel welded. It now passes the swinging arm test with the .278 link and EGW OS slidestop. The lug impacts at a different point in the VIS. Shots fired, seems to function ok. Accurate and reliable with hardball. LSWC need not apply though. 'Will be trying the .2755 link from Dawson Precision next to have more clearance. Doing tuner's test for a long link (gun upside down, etc...), the slide barely clears the barrel locking lug.

I'd considered suggesting welding up the rear of the lug a little... since it would require so little to close the gap... but hesitated because I'm not sure what the barrel steel is... but what the Jello... Nothin' ventured, nothin' gained.

On the clearance issue... With the slidestop removed... Can you get the barrel to drop lower, or is it completely on the bed? Be careful with a shorter link. Your vertical dimensions won't let you go much shorter than .278 inch, and if you start the linkdown too early... before the pressure is off the lugs... you can do similar damage... or worse if the link is too short to get the lugs completely clear of the slide.

If the barrel is fully in bed, you can remove about .005 inch from the bed to get a little more clearance.

Another problem with short-linking is that... even if the timing isn't too early... you can cause the barrel to hit the frame bed before it hits the VIS. That can crack the lower lug at the rear, and cause it to separate from the barrel. I've seen'em pull completely through to the chamber... which can be bad JuJu of the ka-boom variety.

"Can you get the barrel to drop lower, or is it completely on the bed?"

Can't get it to drop any further, it's completely on the bed.

I'll leave the .278 link alone, don't wanna see any of those KB.

BTW, the welder (an engineer) assured me that the weld job couldn't have hurt the integrity of the metal enough for me to worry about. Don't know what kind of welding he did.

So guys, do you think a new OS Hardfit/Gunsmith barrel that's of the standard variety can work with my out-of-spec frame? Any of you know how fat the backside of a Kart barrel lug is?

IIRC, this frame has an improperly machine VIS. I know this isn't an oversize frame, but can't you lower the barrel bed? That would get the VIS contact one needs. What is the barrel bed's measurement above the slide stop centerline?

Or this doesn't work, a ramped barrel would fix that. That was addressed earlier. What's to lose if the approach is done correctly...

Measured the depth from the bed to bottom of dust cover...

Measured the depth from top of pin to bottom of dust cover...

First measurement less the second add half of the pin diameter = 0.362 estimated distance from bed to slide stop hole centerline… best estimate I could do.

I like the idea of taking some metal off the bed.

If I visualize it correctly, this will give me some more clearance since the barrel will sink lower in recoil. This will also effectively allow the barrel to move further back possibly allowing it to make contact with the VIS. The barrel ramp will move back but so will the frame ramp.

Question: If .005 were taken off the bed, how much backward barrel movement will be gained?

Then if that doesn't work I’ll go and look for a ramped barrel and a good gunsmith. The first seems to be the easier of the two.

Going on your dimension from stop pin to the top of the frame rails, it would be a normal assumption that the frame bed itself is also a bit high, so removing a few thousandths... carefully... to provide more barrel drop clearance is reasonable.

A couple of things to be aware of:

First...

When the barrel links down and drops, it should strike the VIS before it hits the bed. It's okay for the barrel to drop an additional couple of thousandths to the bed... as long as it does it after it stops on the VIS, and as long as there is ample clearance between barrel and slide without the extra drop.

Correctly dimensioned, there should be a hair's breadth of clearance between barrel and bed when the barrel is fully down... but it's not absolutely necessary as long as the barrel doesn't hit the bed first.

Second...

Removing material from the bed will increase the gap between the top corner of the feed ramp and the lower edge of the barrel ramp... which is beneficial in that it increases the clearance between the bullet nose and the barrel ramp as the round feeds. What many people don't realize is that the barrel ramp isn't a bullet guide. It's a clearance angle. The bullet nose isn't supposed to touch any part of the barrel ramp except at the top corner... and only then on the bullet ogive... and right ON the corner as the round begins to break over to horizontal for its entry into the chamber. This aids in smooth, sure feeding and prevents the too-frequent occurrence of our old nemesis, the "3- Point Jam" because... as the bullet enters the chamber and breaks over, the small amount of "Stem Bind" present because of the controlled-feed function exerts a downward force on the barrel... keeping it in bed, and its angle as low as possible until the cartridge is nearly completely chambered. Once the round is nearly seated, the breechface contacts the barrel hood and times the barrel forward and up... properly into the slide.

If the bullet nose strikes too low on the barrel ramp, it pushes the barrel forward. As the barrel moves forward, it also moves up. If the barrel lugs try to enter the slide's lugs too early... you get a 3-Point Jam.

On a final note... "Stem Bind" is misleading, and often presented as a bad thing. Excessive stem bind is the problem. A certain amount of stem binding is always present in a Browning tilting barrel design... and as long as it's not excessive, it contributes to reliability instead of detracting from it.

Took the plunge. Took off .005 from the bed. ARMSCOR barrel with .278 link now passes the swinging arm test. Still the top of lug#1 shows impact marks... a little smaller than the one before, but it's still there.

Batoy... Check the clearance with the gun upside down. If the barrel falls back up toward the slide and eliminates the clearance, you may need a shorter link. It can close it up a little, but with all the slack taken out of the link, the barrel should still have some clearance. Another way to check for it is to insert a wooden dowel rod in the barrel, all the way back to the chamber... and lever the rear of the barrel up to remove the clearance.

This should be done at the correct linkdown timing point at .250 inch of slide travel. If there's any difference in the clearance with the slack taken out of the link, it shouldn't exceed a third of the total. Example: If you've got .015 inch before the slack is out, there should still be a minimum of .010 inch WITH the slack out.

quote:

"Check the clearance with the gun upside down. If the barrel falls back up

toward the slide and eliminates the clearance"

Barrel falls back to the slide, Tuner. I'll order some short links tonight from Dawson Precision, both .2755 and .273. Here are some photos...

I did gain some more gap between the barrel throat and frame ramp.